Guanyu Hou, Bin Wu, Rongfang He, Weibin Zhang. Three-Dimensional Measurement Method of Defects Based on Binocular Grating Reconstruction and Texture Mapping[J]. Acta Optica Sinica, 2022, 42(7): 0712003

Search by keywords or author

- Acta Optica Sinica

- Vol. 42, Issue 7, 0712003 (2022)

Fig. 1. Schematic diagram of binocular grating projection reconstruction system

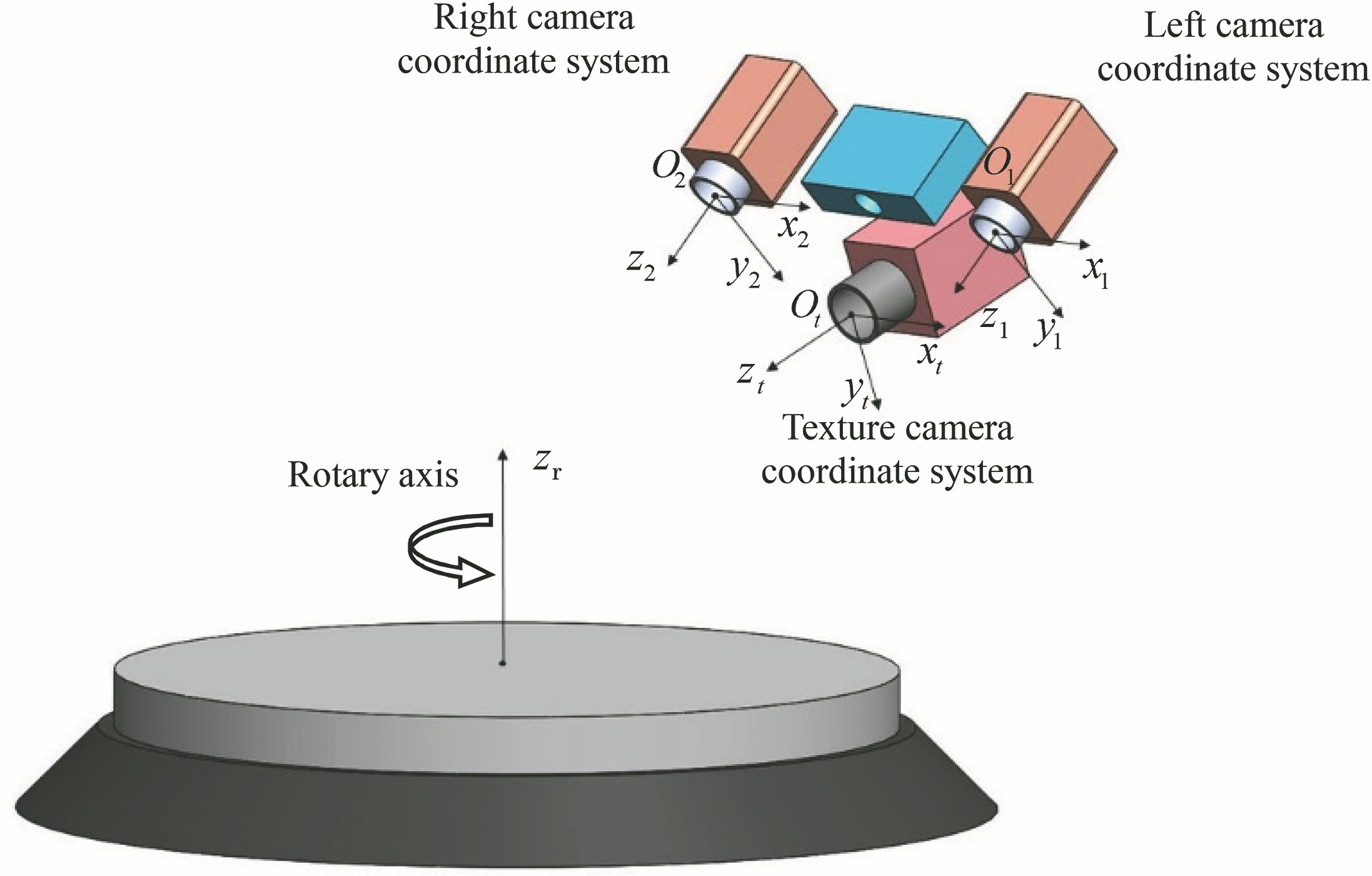

Fig. 2. 3D reconstruction system with turntable and texture camera

Fig. 3. Comparison of effect of texture mapping before and after occlusion judgment. (a) Original point cloud data; (b) direct apping result; (c) texture image; (d) mapping result after occlusion judgment (eliminated points are displayed in black)

Fig. 4. Segmentation and search method of finding four closest points

Fig. 5. Conversion of selected image pixels to spatial points

Fig. 6. Measurement system structure

Fig. 7. Two kinds of test objects and their defect labels. (a) Test object 1; (b) test object 2

Fig. 8. Reconstruction results of 5 scratches on the inner surface of the test object 1. (a) Reconstruction result obtained by the interpolation method proposed in this paper; (b) reconstruction result by using the method of direct searching to find the point cloud in the contour

Fig. 9. Comparison of measured defect widths and results of image measurement instrument

Fig. 10. Reconstruction results of surface defects of test object. (a) Reconstruction result after point cloud interpolation; (b) reconstruction result obtained by using method of direct searching point clouds in contour

Fig. 11. Defect distance measurement data and error

|

Table 1. Defect width measurement data and error

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 2. Simulated defect area measurement results

Set citation alerts for the article

Please enter your email address