Tian Tian, Min Li, Yiwei Ma, Song Li, Tao Geng, Libo Yuan, "Highly sensitive vector bending sensor based on chirped core fiber structure," Chin. Opt. Lett. 23, 021204 (2025)

Search by keywords or author

- Chinese Optics Letters

- Vol. 23, Issue 2, 021204 (2025)

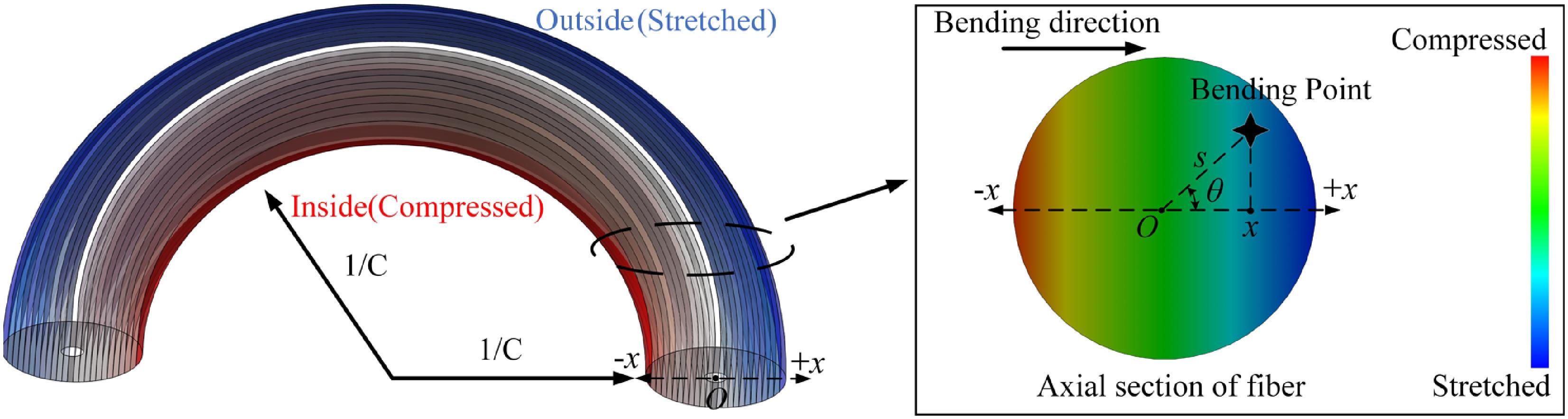

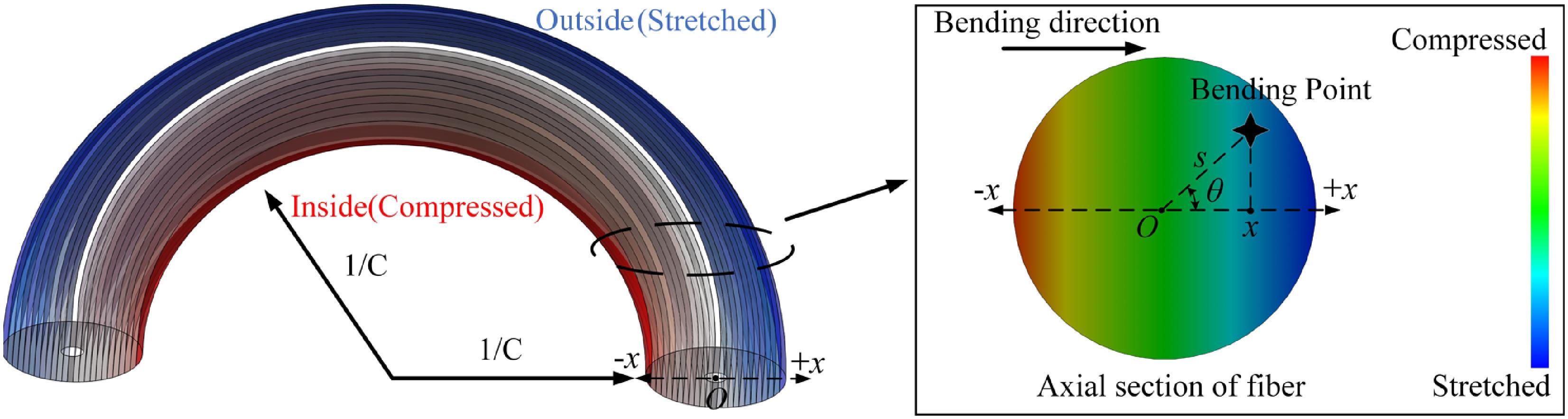

Fig. 1. Schematic diagram of fiber bending. The surface over fiber axis and perpendicular to the bending direction is the neutral surface where x = 0. (s, θ) is the polar coordinate of the bending point.

Fig. 2. (a) Schematic diagram of the CC-MZI based on the SCF. (b) Light distributions on the vertical axis plane of the SCF for different values of the mis-core. (c) Comparison of the transmission spectra of Eq. (1 ) (l = 4.2 mm) and three samples of CC-MZIs.

Fig. 3. (a) Fabrication steps of the CCS. (b) Real image of the CCS through a microscope. (c) Micrograph of the off-axis splicing between the SCF and the CCS.

Fig. 4. Schematic diagram of off-axis splicing using a fiber fusion splicer. (a) Fiber position distribution in the x–y plane. (b) Fiber position distribution in the x–z plane. (c) Structure observed from the y–z plane.

Fig. 5. (a) Schematic diagram of the bending and temperature measurement platform. (b) Definition of bending direction.

Fig. 6. (a) Variation of the broad spectrum with curvatures in the 0°, 90°, and 180° directions. (b) Spectral potential corresponding to the interference peak in the bending direction. The variation of transmission spectra with different curvatures at (c) 0°, (d) 90°, and (e) 180°.

Fig. 7. Fitting curves between the wavelength and the curvature at bending directions of 0°, 90°, and 180°. (a) Dip A. (b) Dip B. (c) Dip B–Dip A. (d) Fitted curve of the bending direction and curvature sensitivity of FSRA-B. (e) Error analysis.

Fig. 8. Linear fitting curves for Dip A and Dip B. (a) Wavelength response to temperature. (b) Wavelength response to strain.

|

Table 1. Parameters of Fibers Used for Preparing CCS

|

Table 2. Comparing the Performance of Different Types of Fiber Optic Curvature Sensors

Set citation alerts for the article

Please enter your email address