Peng Song, Yang Bai, Chao Yang, Chuang Li, Changxi Xue, Jiawen Ding, Jie Guo. Turning method for correcting centrifugal force error of large-diameter off-axis aspheric surface[J]. Infrared and Laser Engineering, 2023, 52(7): 20220888

Search by keywords or author

- Infrared and Laser Engineering

- Vol. 52, Issue 7, 20220888 (2023)

Fig. 1. Experimental diagram of SPDT

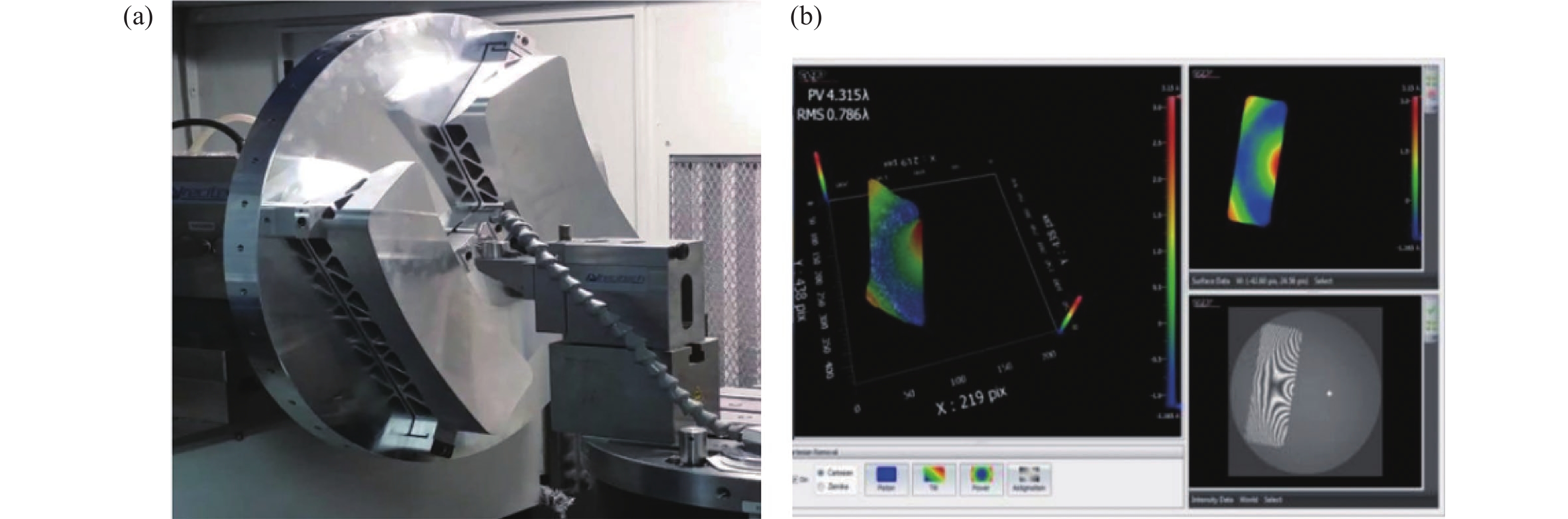

Fig. 2. (a) Machining process and (b) processing results of aluminum alloy off-axis aspheric mirror

Fig. 3. Centrifugal force deformation process. (a) Initial blank surface shape; (b) Centrifugal force loading elastic deformation; (c) Turning process; (d) Centrifugal force unloading elastic recovery

Fig. 4. Off-axis aspheric processing model. (a) Traditional processing model; (b) Suppression centrifugal force coordinate transformation machining model

Fig. 5. Simulation process of centrifugal force deformation

Fig. 6. Simulation results of centrifugal force deformation. (a) Simulation result; (b) The lowest point X -Y cross section; (b) The lowest point Z -Y cross section

Fig. 7. Off-axis aspheric surface morphology. (a) Traditional processing model; (b) Suppression centrifugal force coordinate transformation machining model

Fig. 8. (a) Physical map and (b) test result of off-axis aspheric surface aluminum alloy

|

Table 1. Off-axis aspheric surface parameters

|

Table 2. Johnson-Cook intrinsic model of 6061 aluminum alloy material

|

Table 3. Processing parameters of SPDT

Set citation alerts for the article

Please enter your email address