Chenxin JIA, Rongfu ZHANG, Mengyuan REN, Zhaohui XU, Yangdan GONGJI, Hanlin LIU. An endoscope welding spot detection system based on FPGA image processing[J]. Optical Instruments, 2022, 44(5): 53

Search by keywords or author

- Optical Instruments

- Vol. 44, Issue 5, 53 (2022)

Fig. 1. Overall block diagram of the system

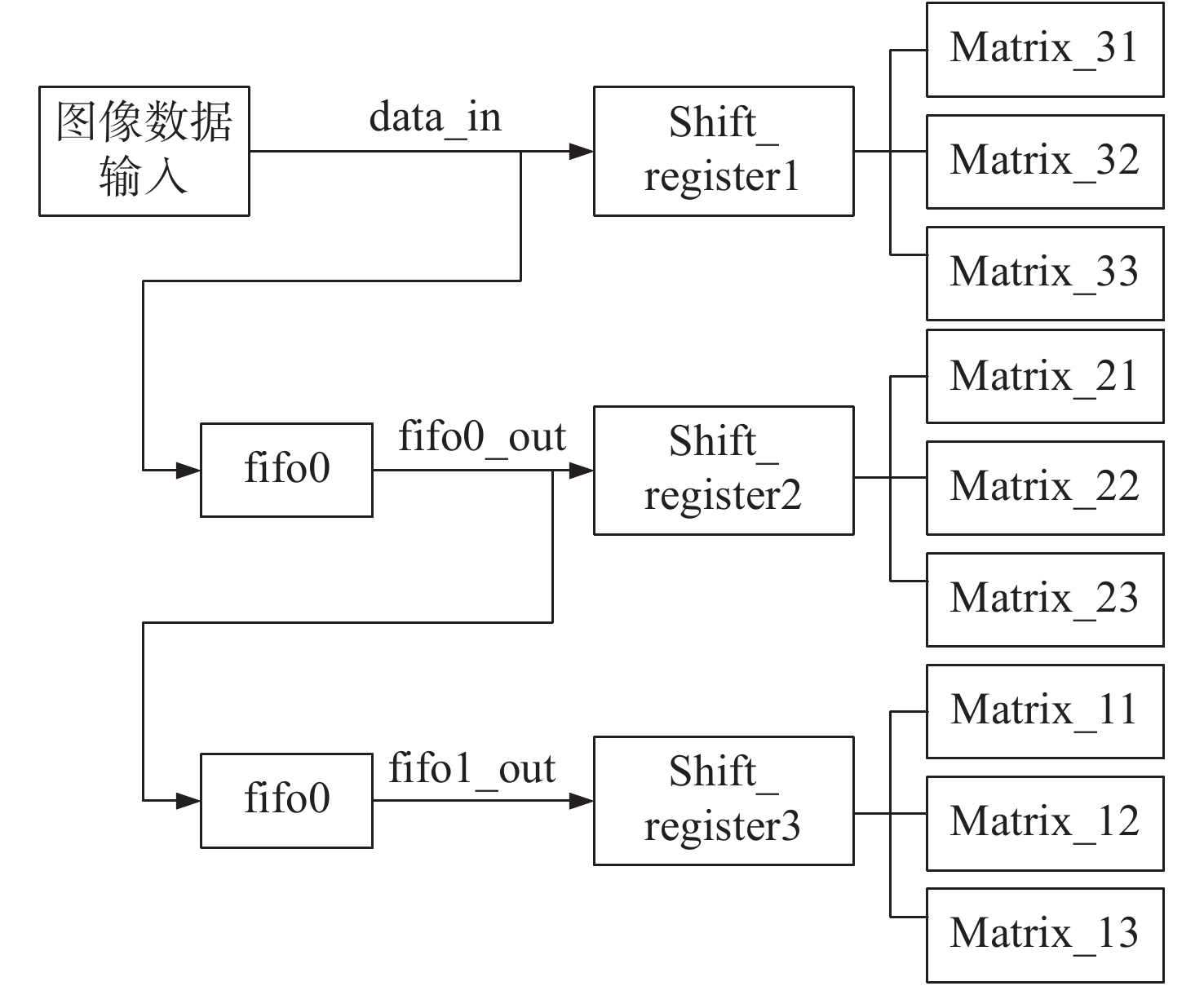

Fig. 2. 3×3 slide window to generate graph

Fig. 3. Effect of image acquisition

Fig. 4. Structure of pixel coordinate system

Fig. 5. Random placement of the target board

Fig. 6. Flow chart of welding point coordinate acquisition

Fig. 7. Linear region segmentation model

Fig. 8. Test platform

Fig. 9. Extraction of coordinates of solder joint

Fig. 10. Defect of target plate

|

Table 1. Comparision between the detected coordinates and the actual coordinates

|

Table 2. Analysis of experimental results of welding spot detection

Set citation alerts for the article

Please enter your email address