Jie LI, Zhixin LUO, Yang CUI, Guangheng ZHANG, Luchao SUN, Jingyang WANG. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 39, Issue 6, 671 (2024)

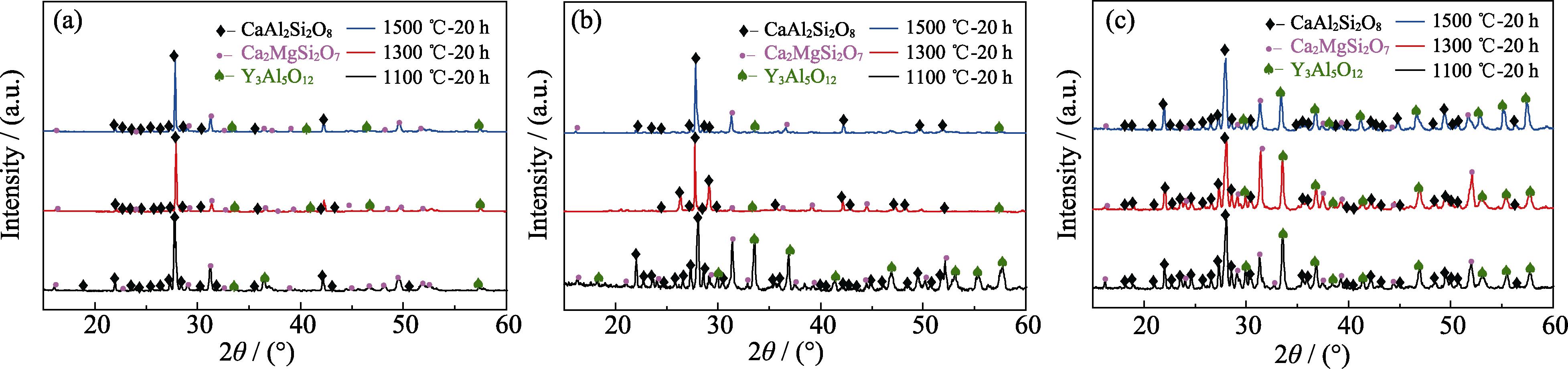

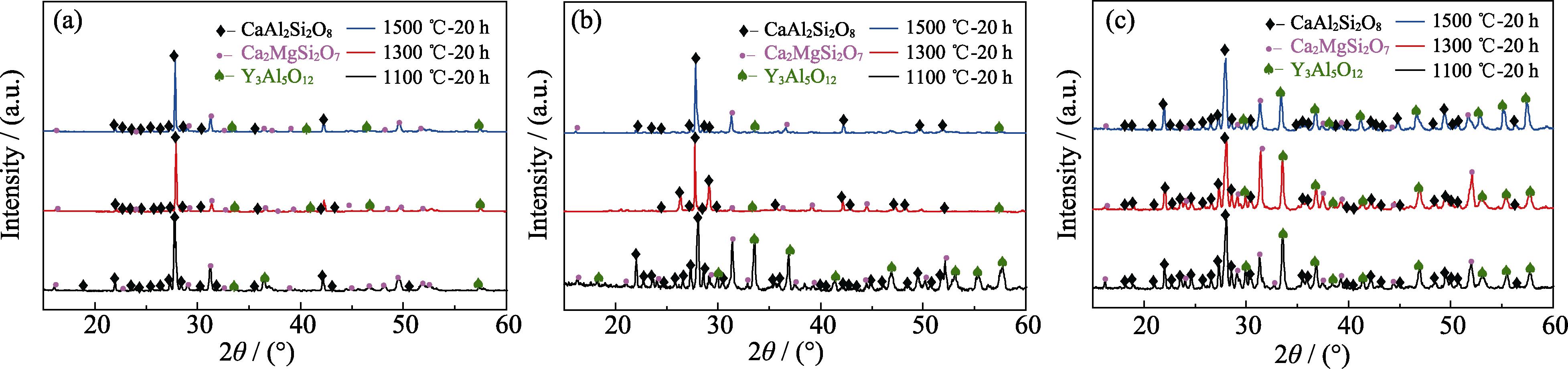

1. XRD patterns of the surfaces of YAG/Al2O3 coatings after CMAS corrosion at 1300 ℃ for (a) 1, (b) 4, and (c) 25 h Colorful patterns are available on website

2. Surface morphologies of YAG/Al2O3 coatings after CMAS corrosion

3. TEM analyses of YAG/Al2O3 coating annealed at 1100 ℃ after CMAS corrosion for 1 h

4. Cross-sectional morphologies of YAG/Al2O3 coatings after CMAS corrosion

5. TEM analyses of YAG/Al2O3 coating annealed at 1300 ℃ after CMAS corrosion for 4 h

6. EDS mappings of the cross-section of YAG/Al2O3 coating annealed at 1100 ℃ after CMAS corrosion for 1 h

7. EDS mappings of the cross-section of YAG/Al2O3 coating annealed at 1500 ℃ after CMAS corrosion for 1 h

S1. High-magnification cross-section observations of YAG/Al2O3 coatings annealed at 1300 ℃ after CMAS corrosion for (a) 1, (b) 4, and (c) 25 h

S2. High-magnification cross-section observations of YAG/Al2O3 coatings annealed at 1500 ℃ after CMAS corrosion for (a) 1, (b) 4, and (c) 25 h

S3. Cross-section observations of (a) as-deposited YAG/Al2O3 coating and coatings annealed at (b) 1100, (c) 1300, and (d) 1500 ℃

S4. Equivalent thickness statistics of precipitation YAG garnet-structure solid solution of coatings annealed at different temperatures

|

Table 1. Atmospheric plasma spraying parameters for YAG/Al2O3 coating

|

Table 1. TEM-EDS results of the regions marked with letters E, F, and G in Fig. 5(c) (%, in atom)

|

Table 2. SEM-EDS analytical results of the phases on the surface of YAG/Al2O3 coating annealed at 1100 ℃ after CMAS corrosion for 1 h (%, in atom)

|

Table 3. SEM-EDS analytical results of phases in the cross-section of YAG/Al2O3 coating annealed at 1300 ℃ after CMAS corrosion for 4 h (%, in atom)

Set citation alerts for the article

Please enter your email address