Aochen DU, Qiyuan DU, Xin LIU, Yimin YANG, Chenyang XIA, Jun ZOU, Jiang LI. Ce:YAG Transparent Ceramics Enabling High Luminous Efficacy for High-power LEDs/LDs [J]. Journal of Inorganic Materials, 2021, 36(8): 883

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 36, Issue 8, 883 (2021)

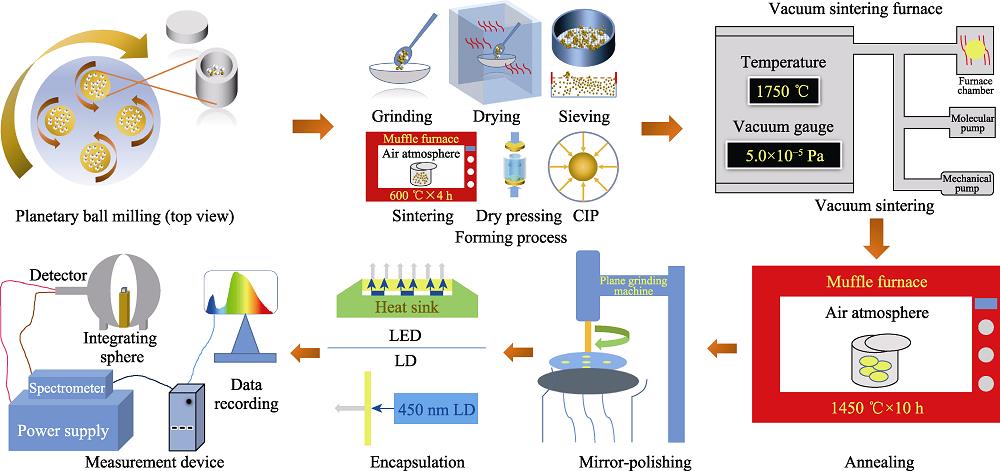

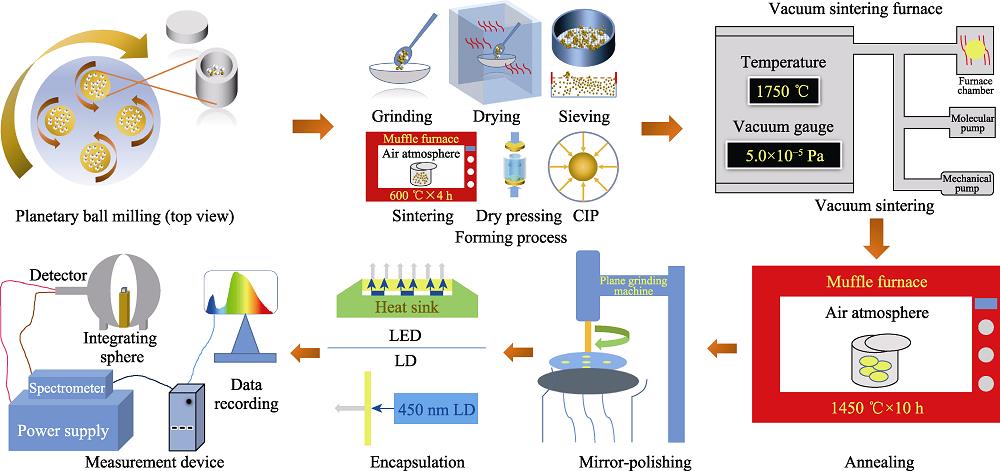

1. Flowchart for the preparation process of Ce:YAG transparent ceramics

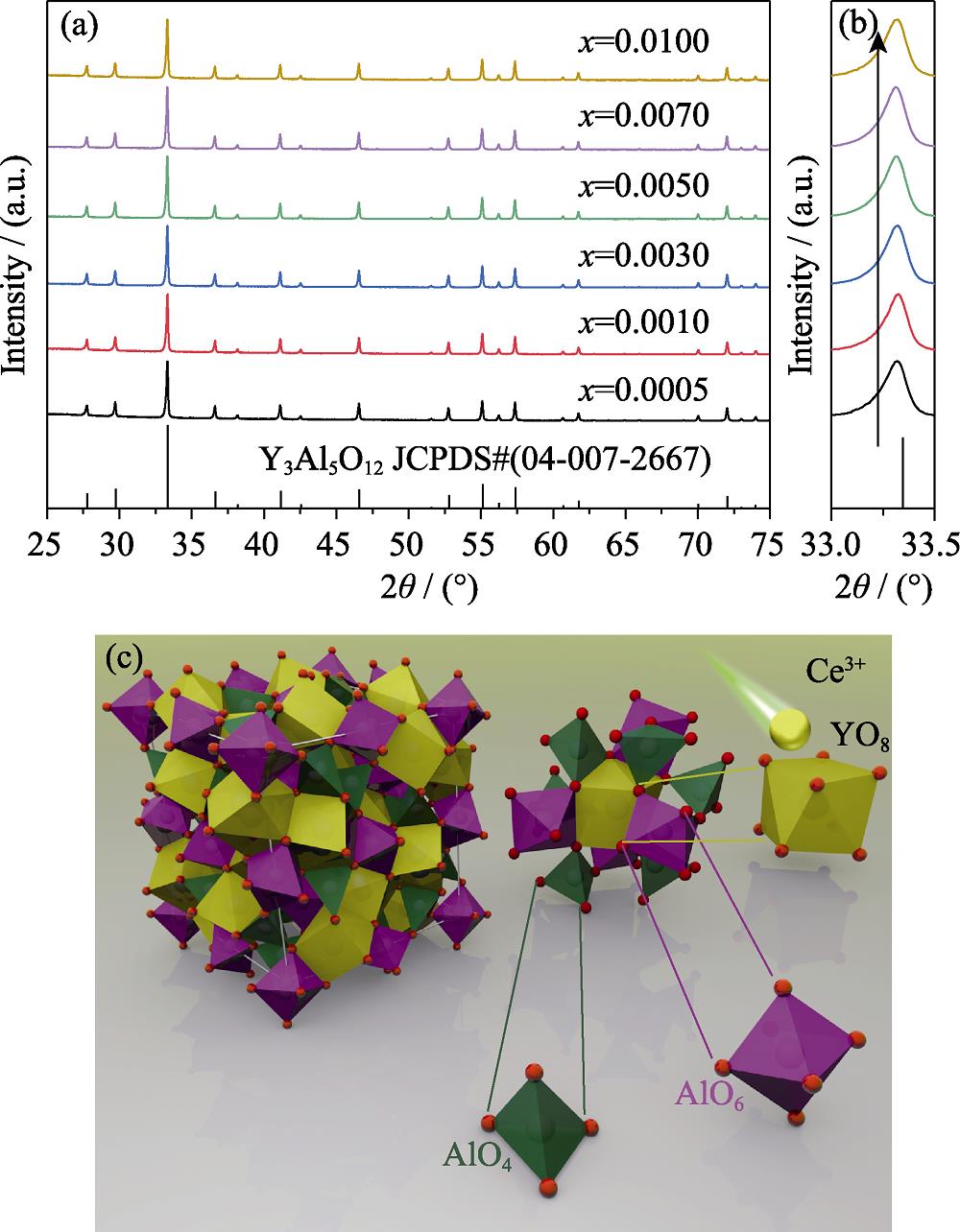

2. XRD patterns (a) of (Cex Y1-x )3Al5O12 transparent ceramics smashed into powder, expanded view (b) of 2θ diffraction peaks between 33.0° and 32.5°, and illustration of Ce:YAG crystalline structure and the coordinated environments (c) of YO8 dodecahedron, AlO4 tetrahedra, and AlO6 octahedra based on JCPDS #04-007-2667

3. FESEM images of the thermally etched surfaces of (Cex Y1-x )3Al5O12 ceramics with different doping concentrations

(a) x =0.0005; (b) x =0.0010; (c) x =0.0030; (d) x =0.0050; (e) x =0.0070; (f) x =0.0100

4. Photographs of all (Cex Y1-x )3Al5O12 ceramics with orthogonally designed parameters under sunlight. All conditions (thickness and concentration) were independent and resulted in the great difference in color from light yellow to deep yellow

(x =0.0005, 0.0010, 0.0030, 0.0050, 0.0070 and 0.0100, d =0.2, 0.4 and 1.0 mm)

5. In-line transmittance curves for annealed and unannealed (Cex Y1-x )3Al5O12 ceramics

(x =0.0005, 0.0010, 0.0030, 0.0050, 0.0070 and 0.0100, d =0.2, 0.4 and 1.0 mm)

6. PLE and PL spectra (a) of (Cex Y1-x )3Al5O12 ceramics, Gaussian deconvolution (b) of the 0.5at%Ce:YAG ceramic with inset showing energy-level scheme of Ce3+, PLE (λ em=525 nm) (c) and PL (λ ex=450 nm) (e) of the prepared Ce:YAG ceramics as the function of Ce3+ doping concentration, the detailed peak positions and emission intensities of PLE (d) and PL (f) spectra of the Ce:YAG ceramics

(x =0.0005, 0.0010, 0.0030, 0.0050, 0.0070 and 0.0100)

7. Thermal quenching behavior (a) for photoluminescence 0.50at%Ce:YAG ceramic phosphor, detailed peak positions and emission intensities of PL spectra (b) of 0.5at%Ce:YAG ceramic, thermal conductivity (c) of (Cex Y1-x )3Al5O12 ceramics at different temperatures, and configurational coordination diagrams (d) illustrating the thermally quenching of 5d-4f luminescence of Ce3+

8. Simplified three-dimensional model view of assemblage and white LEDs encapsulation model (TOP figure), thermal distribution of 0.5at%Ce:YAG transparent ceramics, thickness 0.2 mm (a, d), 0.4 mm (b, e), 1.0 mm (c, f) respectively, during steady thermal state or transient thermal state, and (g-i) three common packaging methods and heat dissipation

9. EL spectra of Ce:YAG ceramics with different doping concentrations (a) and thickness (b), CIE of the LEDs with Ce:YAG ceramics of different doping concentrations (c) and thicknesses (d), the pictures of the LEDs with Ce:YAG ceramics with the increase of doping concentrations and thickness, which changes from blue to yellow (e-g)

10. EL spectra of Ce:YAG ceramics with different doping concentrations (a) and thicknesses (b), CIE of the LDs with Ce:YAG ceramics of different doping concentrations (c) and thicknesses (d)

11. Packaged LEDs devices from blue to yellow arbitrarily by adjusting the Ce3+ concentration and the thickness of transparent ceramics

|

Table 1.

White light emission parameters of Ce:YAG packaged devices ((Ce

Set citation alerts for the article

Please enter your email address