Benting ZHU, Guomin WU. Numerical simulation on truncated oval-nosed projectile penetrating into stiffened plate[J]. Chinese Journal of Ship Research, 2022, 17(6): 244

Search by keywords or author

- Chinese Journal of Ship Research

- Vol. 17, Issue 6, 244 (2022)

![[in Chinese]](/richHtml/CJSR/2022/17/6/244/img_1.jpg)

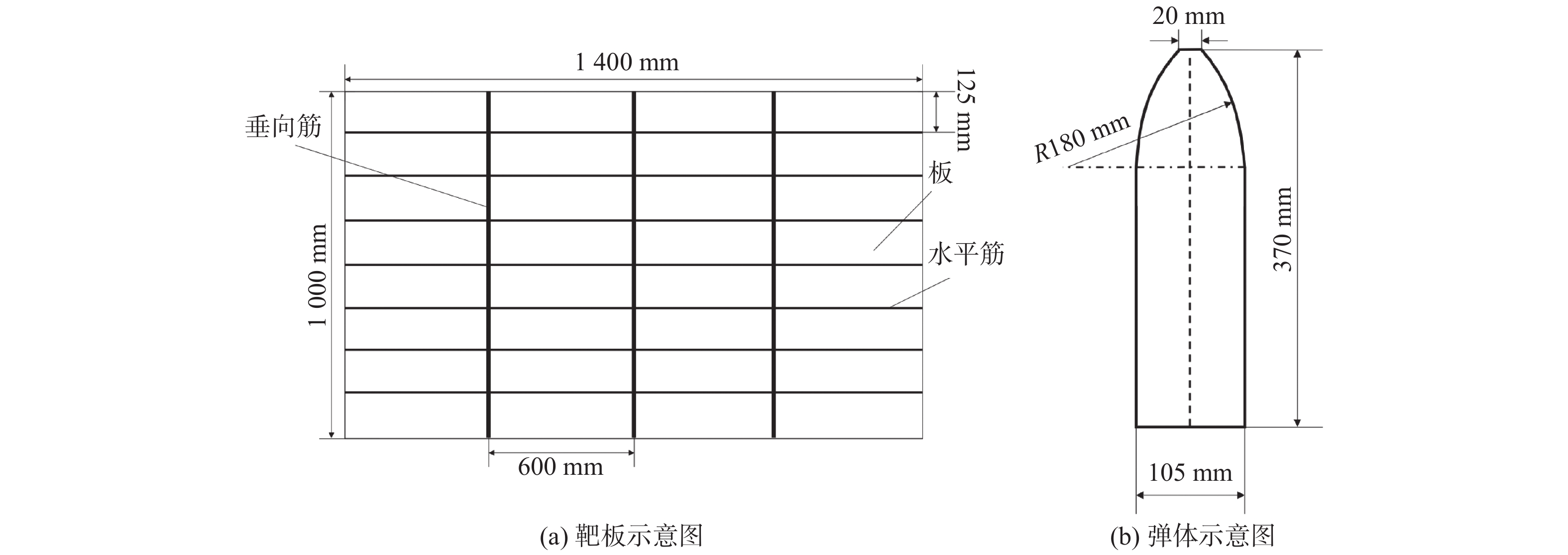

Fig. 1. [in Chinese]

![[in Chinese]](/richHtml/CJSR/2022/17/6/244/img_2.jpg)

Fig. 2. [in Chinese]

Fig. 3. [in Chinese]

Fig. 4. [in Chinese]

Fig. 5. [in Chinese]

Fig. 6. [in Chinese]

Fig. 7. [in Chinese]

Fig. 8. [in Chinese]

Fig. 9. [in Chinese]

Fig. 10. [in Chinese]

|

Table 1. Material parameters

|

Table 2. Comparison of numerical and experimental results

|

Table 3. Energy absorption of each part of stiffened plate at different initial velocities

|

Table 4. Influence of rectangular stiffeners on projectile trajectory

|

Table 5. Influence of T-stiffeners on missile flight trajectory

Set citation alerts for the article

Please enter your email address