Nan YANG, Tianle CHENG, Guangyuan SHI, Yuxin PI, Minchao CUI. Effect of hardness of TC4 titanium alloy samples on laser‐induced plasma temperature[J]. Chinese Journal of Quantum Electronics, 2024, 41(3): 522

Search by keywords or author

- Chinese Journal of Quantum Electronics

- Vol. 41, Issue 3, 522 (2024)

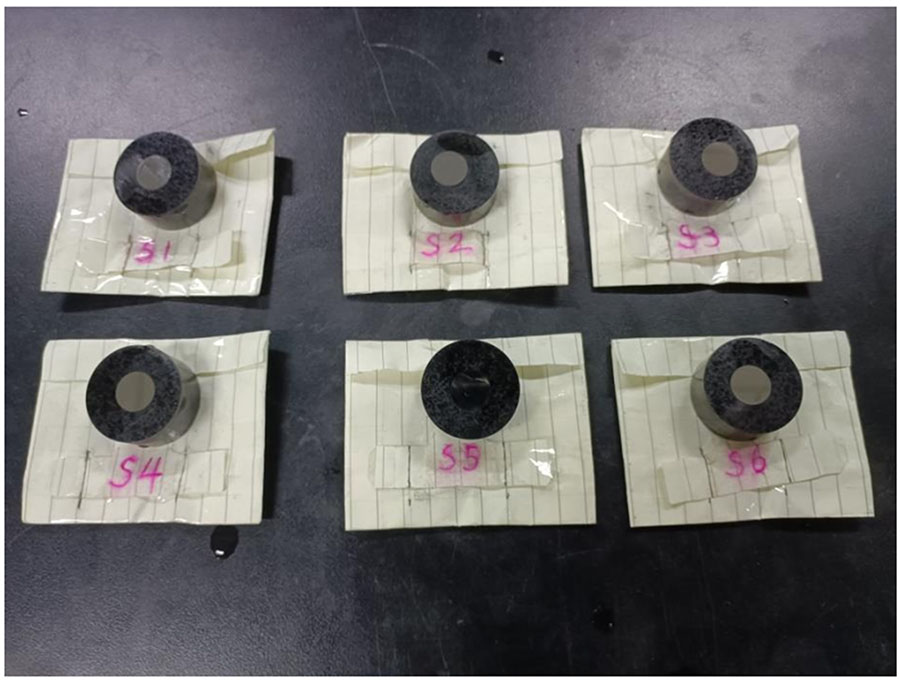

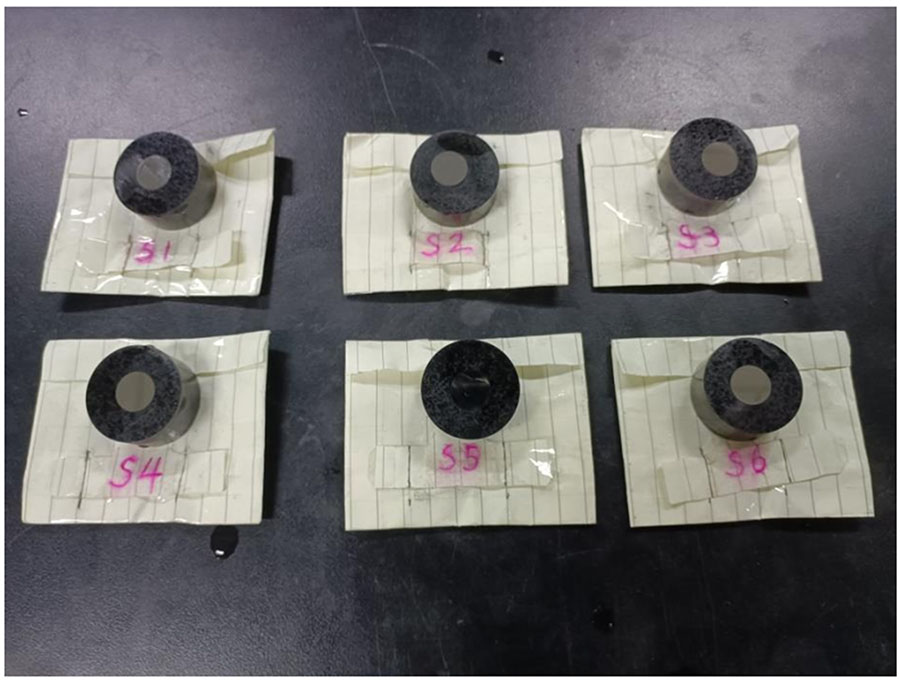

Fig. 1. Six samples after heat treatment and inlay

Fig. 2. Schematic diagram of the LIBS experimental setup for TC4 titanium alloy detection

Fig. 3. Timing diagram of laser-induced plasma radiation spectrum

Fig. 4. LIBS pulse laser ablation crater on the surface of the sample. (a) Macroscopic schematic diagram of ablation crater;(b) Microscopic schematic diagram of ablation crater

Fig. 5. Spectral line intensity of Al versus the hardness for 6 samples. (a) Al Ⅱ 281.619 nm; (b) Al Ⅰ 396.152 nm

Fig. 6. Spectral intensity ratio of Al Ⅱ 281.619 nm and Al Ⅰ 396.152 nm for 6 samples

Fig. 7. Spectral intensity ratio of Al Ⅱ 281.619 nm and Al Ⅰ 396.152 nm versus the hardness of TC4 samples

Fig. 8. Boltzmann plots of 6 TC4 titanium alloy samples with different hardness. (a) S1; (b) S2; (c) S3; (d) S4; (e) S5; (f) S6

Fig. 9. Plasma excitation temperatures versus the hardness of TC4 samples

|

Table 1. Chemical compositions of TC4 titanium alloy

|

Table 2. Hardness values of the TC4 titanium alloy samples

|

Table 3. Spectral parameters of Al II characteristic spectral lines[21]

Set citation alerts for the article

Please enter your email address