- Opto-Electronic Advances

- Vol. 7, Issue 12, 240222 (2024)

Abstract

Transparent materials, such as sapphires, diamonds, and quartzs, have excellent material properties

High repetition rate femtosecond laser has shown its unique advantages in many material processing fields

In the recent work published in Opto-Electronic Science

![]()

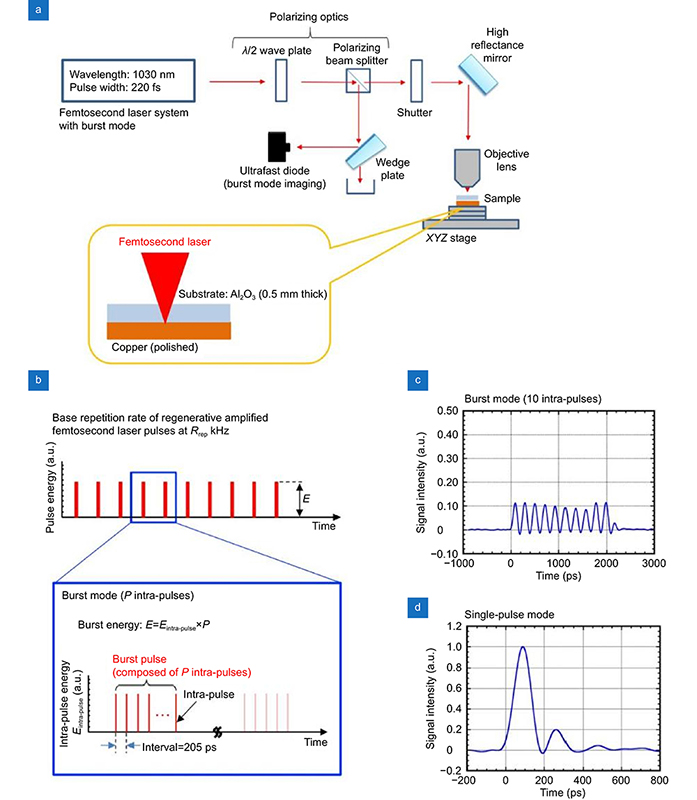

Figure 1.Experimental setup for the GHz burst mode fs-LIPAA process.

References

[1] SF Wang, J Zhang, DW Luo et al. Transparent ceramics: processing, materials and applications. Prog Solid State Chem, 41, 20-54(2013).

[2] HG Liu, WX Lin, MH Hong. Hybrid laser precision engineering of transparent hard materials: challenges, solutions and applications. Light Sci Appl, 10, 162(2021).

[3] TY Yan, LF Ji. Ultrafast laser filamentation in transparent solids. Ultrafast Sci, 3, 0023(2023).

[4] J Zhang, K Sugioka, K Midorikawa. Direct fabrication of microgratings in fused quartz by laser-induced plasma-assisted ablation with a KrF excimer laser. Opt Lett, 23, 1486-1488(1998).

[5] MH Hong, K Sugioka, YF Lu et al. Laser microfabrication of transparent hard materials and signal diagnostics. Appl Surf Sci, 186, 556-561(2002).

[6] YL Zhao, TY Yan, MH Hong. Enhancement of laser-induced plasma-assisted ablation of glass substrate via interacting spatial double laser pulse irradiation. Opt Laser Technol, 180, 111588(2025).

[7] Y Hanada, K Sugioka, I Miyamoto et al. Double-pulse irradiation by laser-induced plasma-assisted ablation (LIPAA) and mechanisms study. Appl Surf Sci, 248, 276-280(2005).

[8] C Kerse, H Kalaycıoğlu, P Elahi et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature, 537, 84-88(2016).

[9] M Park, YR Gu, XL Mao et al. Mechanisms of ultrafast GHz burst fs laser ablation. Sci Adv, 9, eadf6397(2023).

[10] K Obata, S Kawabata, Y Hanada et al. High performance micromachining of sapphire by laser induced plasma assisted ablation (LIPAA) using GHz burst mode femtosecond pulses. Opto-Electron Sci, 3, 230053(2024).

[11] ZY Lin, K Liu, T Cao et al. Microsphere femtosecond laser sub-50 nm structuring in far field via non-linear absorption. Opto-Electron Adv, 6, 230029(2023).

[12] JB Yin, YZ Li, ZW Chen et al. Formation of armored silicon nanowires array via high-repetition-rate femtosecond laser oxidation for robust surface-enhanced Raman scattering detection. ACS Appl Mater Interfaces, 16, 48667-48675(2024).

[13] LM Jia, L Cheng, W Zheng. 8-nm narrowband photodetection in diamonds. Opto-Electron Sci, 2, 230010(2023).

[14] Z Wang, B Zhang, DZ Tan et al. Ostensibly perpetual optical data storage in glass with ultra-high stability and tailored photoluminescence. Opto-Electron Adv, 6, 220008(2023).

Set citation alerts for the article

Please enter your email address

AI Video Guide

AI Video Guide  AI Picture Guide

AI Picture Guide AI One Sentence

AI One Sentence