Shi FU, Zengchao YANG, Honghua LI, Liang WANG, Jiangtao LI. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 37, Issue 9, 947 (2022)

1. XRD patterns of Si3N4 ceramics with different additive systems prepared by hot pressing sintering

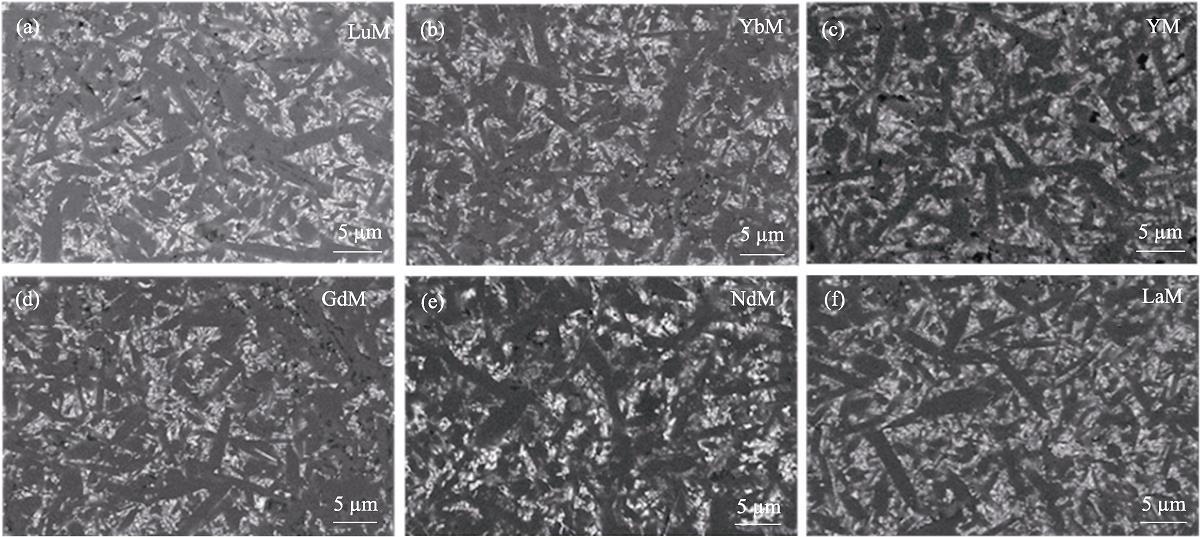

2. SEM images of the polished surfaces of Si3N4 ceramics with different additive systems prepared by hot pressing sintering

3. XRD patterns of Si3N4 ceramics with different additive systems after annealing

4. SEM images of the polished surfaces of Si3N4 ceramics with different additive systems after annealing

5. (a) Average grain size, (b) bending strength, (c) fracture toughness, and (d) thermal conductivity changing with radius of rare earth ion of Si3N4 ceramics before and after annealing

6. Microstructures of Si3N4 ceramic samples before and after annealing

|

Table 1. Properties of Si3N4 ceramic samples prepared by hot pressing sintering

Set citation alerts for the article

Please enter your email address