Fuxin PENG, Zhongwei HU, Yu CHEN, Binhui XIE, Zhihao ZHOU. Surface crack depth detection of sapphire substrate two-sided lapping[J]. Optics and Precision Engineering, 2023, 31(14): 2060

Search by keywords or author

- Optics and Precision Engineering

- Vol. 31, Issue 14, 2060 (2023)

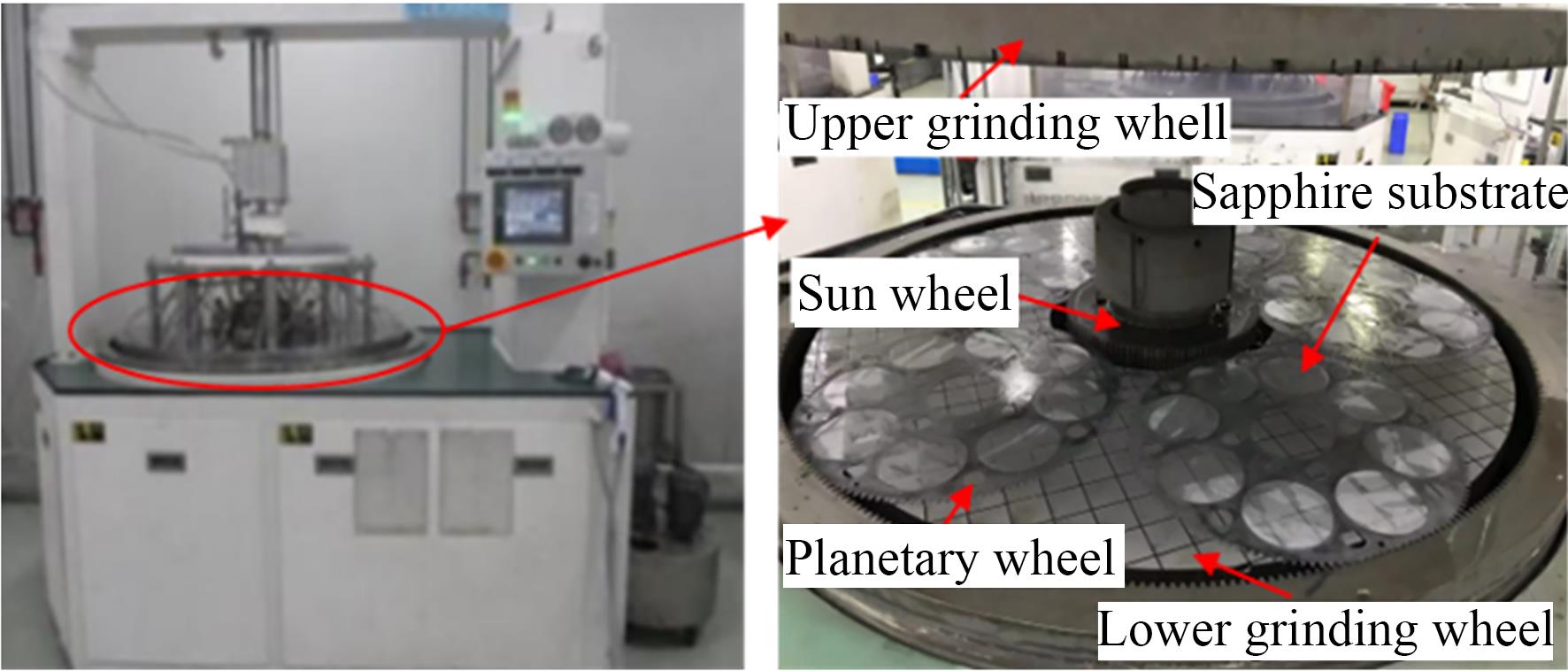

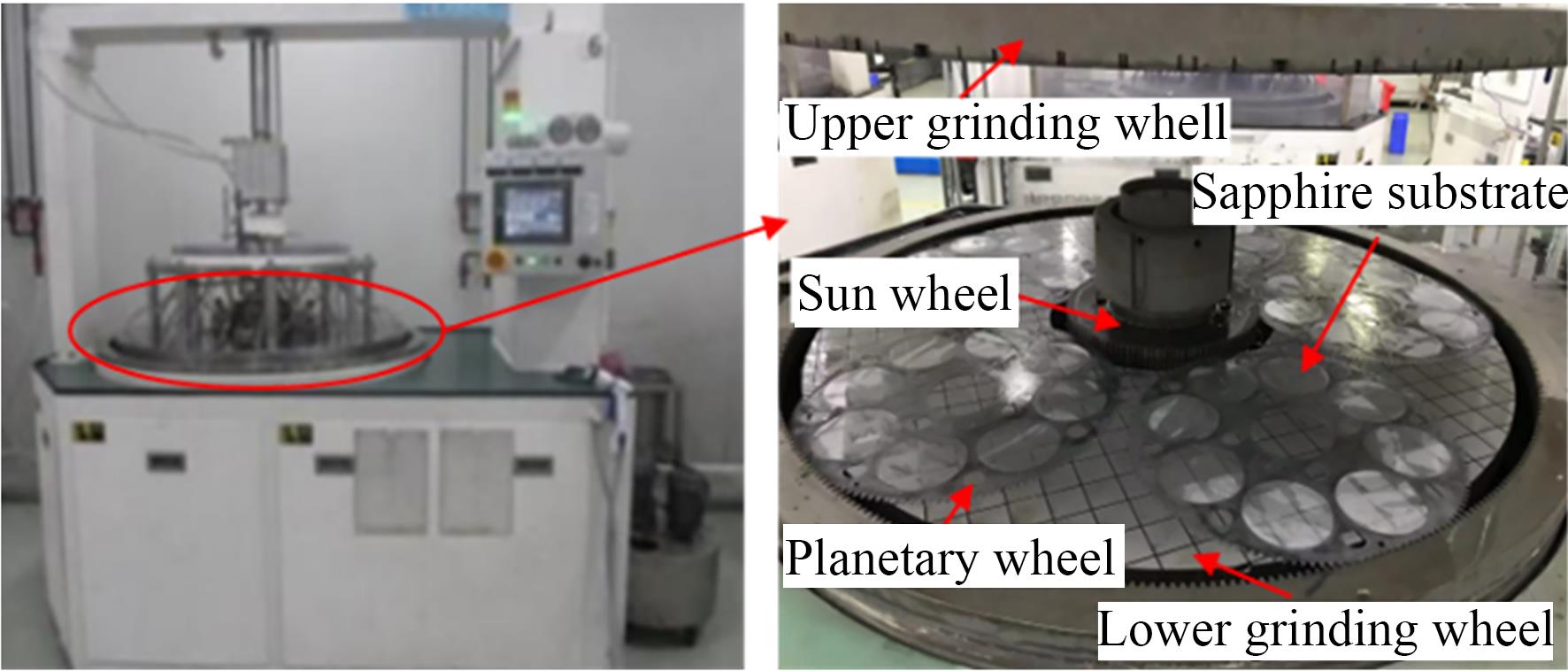

Fig. 1. Double side grinding machine

Fig. 2. Section microscopic observation method sample

Fig. 3. Principle of Focused Ion Beam Side Observation

Fig. 4. High temperature etching machine

Fig. 5. Grinding sapphire substrate etching rate curve

Fig. 6. Magnetorheological polishing sapphire substrate

Fig. 7. Magnetorheological polishing spot midline contour curve

Fig. 8. CMP Polishing machine

Fig. 9. Polishing cross section cracks on double side grinding sapphire substrate

Fig. 10. Cross section crack of focused ion beam in double side polished sapphire wafer

Fig. 11. Differential etching rate curve of grinding sapphire

Fig. 12. Surface morphology changes of sapphire after grinding for 30-40 min

Fig. 13. Surface morphology of different points on the midline of polishing spot

Fig. 14. Surface morphology of polished sapphire layer by layer

Fig. 15. Models of surface and subsurface cracks on double-sided grinding sapphire substrate

|

Table 1. Crack depth measured by different methods

Set citation alerts for the article

Please enter your email address