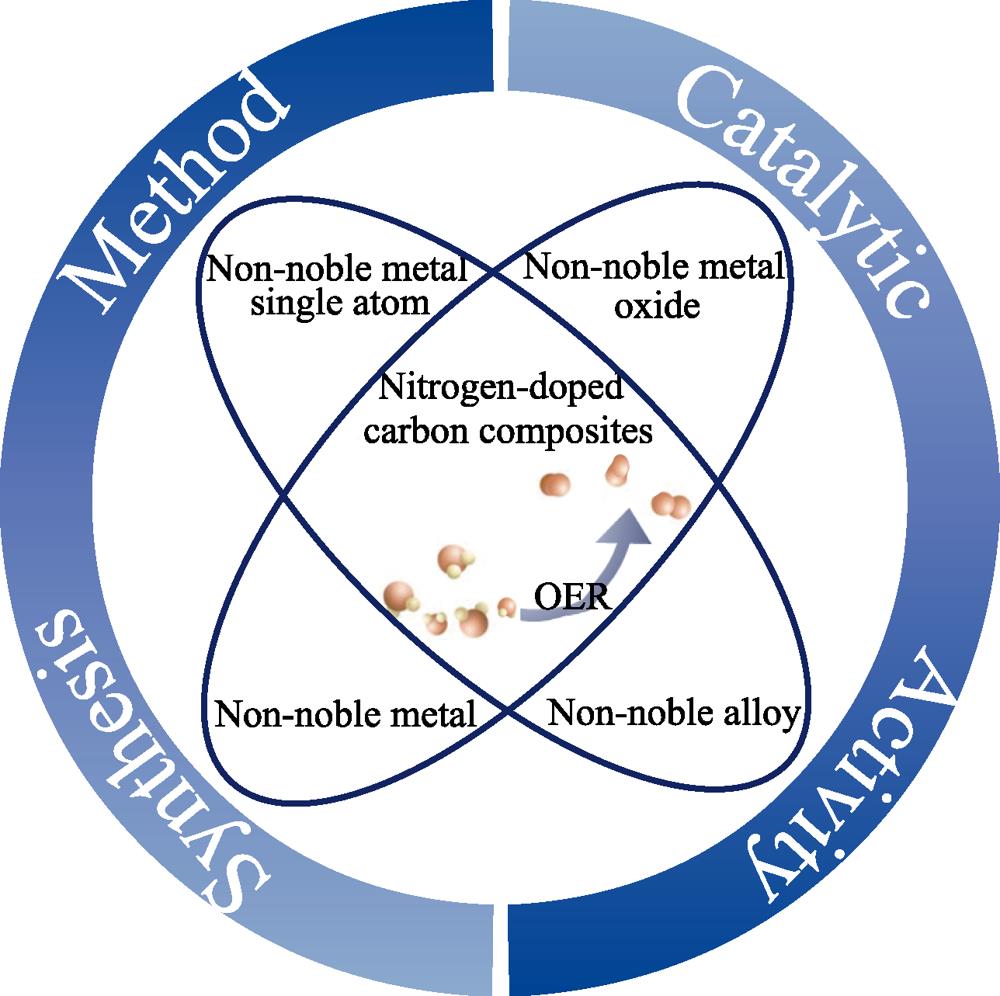

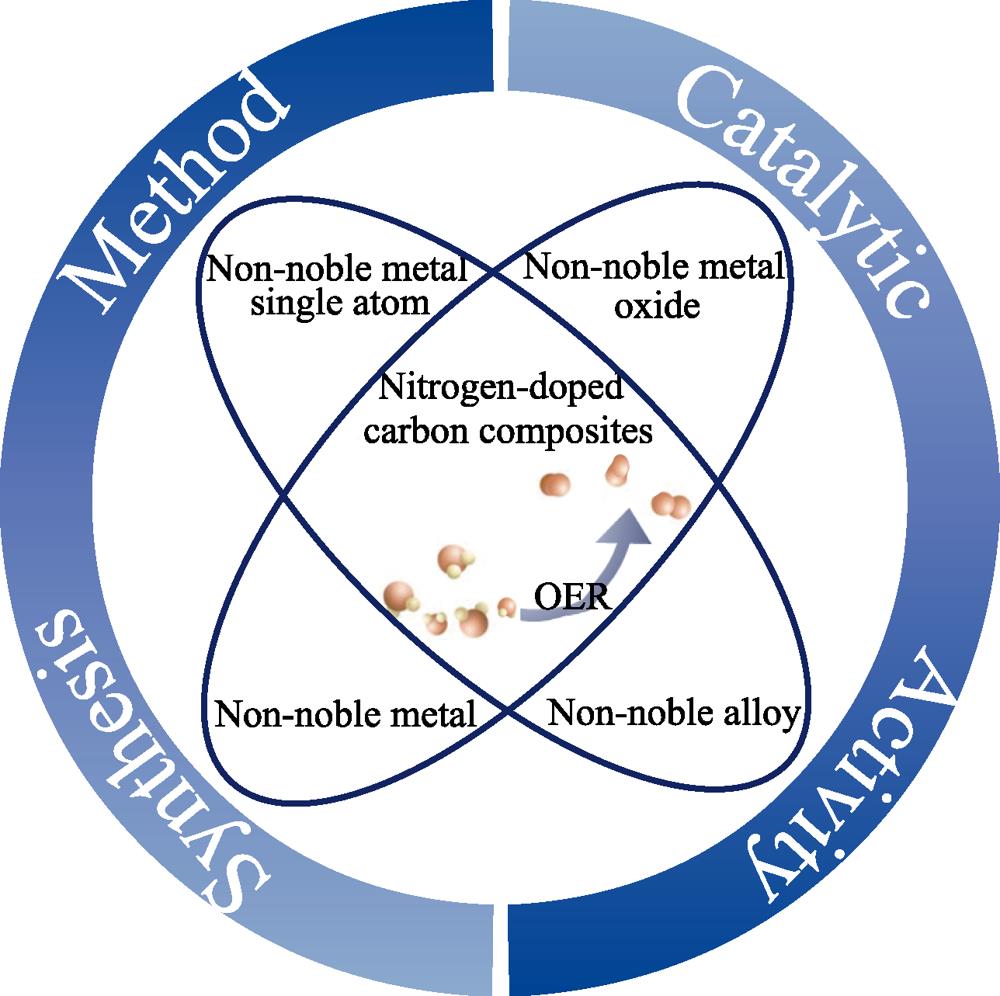

Yongsheng FU, Min BI, Chun LI, Jingwen SUN, Xin WANG, Junwu ZHU. Research Progress on Non-noble Metal/Nitrogen-doped Carbon Composite Materials in Electrocatalytic Oxygen Evolution Reaction [J]. Journal of Inorganic Materials, 2022, 37(2): 163

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 37, Issue 2, 163 (2022)

1. Classification of non-noble metal/nitrogen-doped carbon composite materials

![Synthesis schemes of (a) Co@CNT/NC composites[23], (b) Co-MOF//NF and Co-NCNTFs//NF[25]; (c) OER polarization curves with 85% iR compensation in a 1 mol·L-1 KOH solution at a scan rate of 1 mV·s-1 and (d) related Tafel plots of Co-MOF//NF, Co-NCNTFs//NF, bare Ni foam, and RuO2[25]; (e) Stability tests of Co-NCNTFs//NF for OER and HER at a current density of 10 mA·cm-2[25]; (f) Illustration of the Co@NC/CC composite fabrication[27]](/richHtml/jim/2022/37/2/163/img_2.png)

2. Synthesis schemes of (a) Co@CNT/NC composites[23], (b) Co-MOF//NF and Co-NCNTFs//NF[25]; (c) OER polarization curves with 85% iR compensation in a 1 mol·L-1 KOH solution at a scan rate of 1 mV·s-1 and (d) related Tafel plots of Co-MOF//NF, Co-NCNTFs//NF, bare Ni foam, and RuO2[25]; (e) Stability tests of Co-NCNTFs//NF for OER and HER at a current density of 10 mA·cm-2[25]; (f) Illustration of the Co@NC/CC composite fabrication[27]

3. (a) “Confined recrystallization” self-template synthesis strategy for Fe-NC SAC[28]; (b) Schematic illustration of the synthetic procedure of the SCoNC catalysts[32]; (c) Schematic description of the synthetic process, (d, e) FESEM and (f) TEM images of the HCM@Ni-N[35]; (g, h) FESEM and (i) TEM images for HCM@Ni-N after continuous operation for 10 h[35]; (j) LSV curves in 1.0 mol·L-1 KOH and (k) the related Tafel plots of HCM@Ni-N, HCM@Ni, HCM@N, and HCM[35]

4. Schematic synthesis process of (a) FeCo@MNC[42], (b) Ni1.5Co0.5 @ N-C NT/NFs[44] and (c) FeNi@NC-x [46]; (d) SEM image of FeNi@NC-2[46]; (e) LSV curves and (f)Tafel plots of RuO2, and FeNi@NC-x [46]; (g) Illustration of the preparation of Ni3Fe-GAs [47]; (h,i) SEM images and (j) TEM image for Ni3Fe-GA1[47]; (k) OER polarization curves and (l) corresponding Tafel plots for Ni3Fe-GAs [47]; (m) Chronopotentiometric curves of Ni3Fe-GA1 and IrO2 catalysts[47]

5. (a) Illustration of the synthesis process of N-Co3O4 and N-CoO/C[59]; SEM images of (b, c) CoO and (d, e) N-CoO nanowire arrays[60]; (f) Illustration of the synthesis process of CoO/Co@N-C[61]; SEM images of (g) Co3O4 and (h) Co3O4@Glu microspheres, and (i) CoO/Co@N-C electrocatalyst[61]; (j) LSV curves and (k) Tafel plots of CoO@N-C, CoO/Co@N-C, CoO/Co@N-C-x samples that etched in HCl with x representing etching time, Ir/C and Pt/C in 0.1 mol·L-1 KOH solution; (l) LSV curves for the CoO/Co@N-C electrocatalyst before and after 2000 CV cycles in 0.1 mol·L-1 KOH solution[61]

|

Table 1. OER electrocatalytic performances of non-noble metal/nitrogen-doped carbon composites

|

Table 2. OER electrocatalytic performances of non-noble metal single atom/nitrogen-doped carbon composites

|

Table 3. OER electrocatalytic performances of non-noble alloy/nitrogen-doped carbon composites

|

Table 4. OER electrocatalytic performance of non-noble metal oxide/nitrogen-doped carbon composites

Set citation alerts for the article

Please enter your email address