[1] DebRoy T, Wei H L, Zoback J S et al. Additive manufacturing of metallic components-process, structure, and properties[J]. Progress in Materials Science, 92, 112-224(2018).

[2] Zhang Y, Wu L M, Guo X Y et al. Additive manufacturing of metallic materials: a review[J]. Journal of Materials Engineering and Performance, 27, 1-13(2018).

[3] Lee H, Lim C H J, Low M J et al. Lasers in additive manufacturing: a review[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 4, 307-322(2017).

[4] Svetlizky D, Das M, Zheng B L et al. Directed energy deposition (DED) additive manufacturing: physical characteristics, defects, challenges, and applications[J]. Materials Today, 49, 271-295(2021).

[5] Liang W X, Yang Y, Jin K et al. Morphology prediction of a coaxial powder feeding multichannel laser cladding layer based on the response surface[J]. Laser & Optoelectronics Progress, 59, 0114012(2022).

[6] Chen F, Song C H, Yang Y Q et al. Surface quality and mechanical properties of 316L stainless steel manufactured by powder feeding laser additive and milling subtractive hybrid manufacturing[J]. Laser & Optoelectronics Progress, 59, 0114009(2022).

[7] Zhang A F, Li D C, Liang S D et al. The development of laser additive manufacturing of high-performance metal parts[J]. Aeronautical Manufacturing Technology, 59, 16-22(2016).

[8] Zhang J C, Shi S H, Gong Y Q et al. Research progress in laser cladding technology[J]. Surface Technology, 49, 1-11(2020).

[9] Guner A, Bidart P, Jiménez A et al. Nozzle designs in powder-based direct laser deposition: a review[J]. International Journal of Precision Engineering and Manufacturing, 23, 1077-1094(2022).

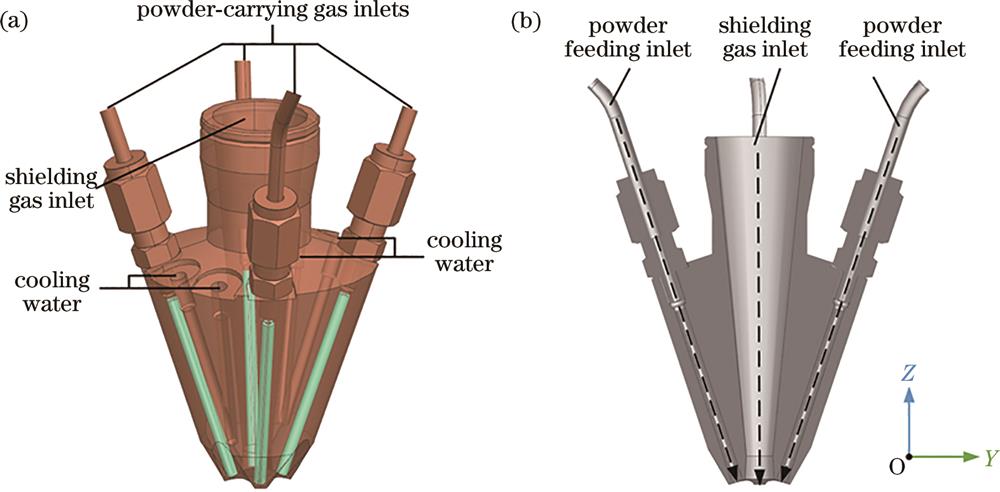

[10] Su P, Li H, Yang J Y et al. Optimal design of structure parameters of the coaxial powder feeding nozzle for laser cladding[J]. Journal of Physics: Conference Series, 1798, 012050(2021).

[11] Wang W, Cai L, Yang G et al. Research on the coaxial powder-feeding nozzle for laser cladding[J]. Chinese Journal of Lasers, 39, 0403003(2012).

[12] Liu H, Yu G, He X L et al. The effect of powder properties on the convergence of the powder stream in coaxial laser cladding[J]. Chinese Journal of Lasers, 40, 0503008(2013).

[14] Zhang Z Y, Lei Y Y, Wang S et al. Numerical simulation of the flow field of the coaxial powder-feeding nozzle for heterogeneous materials[J]. Journal of Machine Design, 38, 57-66(2021).

[15] Ferreira E, Dal M, Colin C et al. Experimental and numerical analyzes of gas/powder flow for different LMD nozzles[J]. Metals, 10, 667(2020).

[16] Zhang A F, Li D C, Zhou Z M et al. Numerical simulation of the powder flow field on a coaxial powder nozzle in laser metal direct manufacturing[J]. The International Journal of Advanced Manufacturing Technology, 49, 853-859(2010).

[17] Zhang A F, Li D C, Zhang L F et al. 3D numerical simulation of coaxial powder feeding nozzle powder convergence characteristics[J]. Infrared and Laser Engineering, 40, 859-863(2011).

[18] Lu Q P, Zhang A F, Li D C et al. Numerical simulation and experimental research on gas-carrier coaxial powder nozzle[J]. Chinese Journal of Lasers, 37, 3162-3167(2010).

[19] Liu H, Hao J B, Yu G et al. A numerical study of metallic powder flow in coaxial laser cladding[J]. Journal of Applied Fluid Mechanics, 9, 2247-2256(2016).

[20] Takemura S, Koike R, Kakinuma Y et al. The design of a powder nozzle for high resource efficiency in directed energy deposition based on computational fluid dynamics simulation[J]. The International Journal of Advanced Manufacturing Technology, 105, 4107-4121(2019).

[21] Li L Q, Huang Y C, Zou C Y et al. A numerical study of the powder stream characteristics of a coaxial laser metal deposition nozzle[J]. Crystals, 11, 282(2021).

[22] Liu Q P, Yang K, Gao Y H et al. An analytical study of powder stream geometry in laser-based direct energy deposition process with a continuous coaxial nozzle[J]. Crystals, 11, 1306(2021).

[23] Zekovic S, Dwivedi R, Kovacevic R. Numerical simulation and experimental investigation of gas-powder flow from radially symmetrical nozzles in laser-based direct metal deposition[J]. International Journal of Machine Tools and Manufacture, 47, 112-123(2007).

[24] Xia Y L, Huang Z, Chen H N et al. Numerical simulation and experimental investigation of powder transport of a new-type annular coaxial nozzle[J]. The International Journal of Advanced Manufacturing Technology, 115, 2353-2364(2021).

[25] Batchelor G K[M]. An introduction to fluid dynamics(1967).

[26] Voller V R, Prakash C. A fixed grid numerical modeling methodology for convection-diffusion mushy region phase-change problems[J]. International Journal of Heat and Mass Transfer, 30, 1709-1719(1987).

[27] Shih T H, Liou W, Shabbir A et al. A new k-ε eddy viscosity model for high Reynolds number turbulent flows[J]. Computers & Fluids, 24, 227-238(1995).

[28] Lateb M, Masson C, Stathopoulos T et al. Comparison of various types of k-ε models for pollutant emissions around a two-building configuration[J]. Journal of Wind Engineering & Industrial Aerodynamics, 115, 9-21(2013).

[29] Jayawickrama T R, Haugen N E L, Babler M U et al. The effect of Stefan flow on the drag coefficient of spherical particles in a gas flow[J]. International Journal of Multiphase Flow, 117, 130-137(2019).