Linjun Zhong, Yongjie Tao, Ping Jiang, Leshi Shu. Process Parameter Optimization for Oscillating Laser Welding of Aluminum Sheet Considering Carbon Emission[J]. Laser & Optoelectronics Progress, 2022, 59(23): 2314002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 59, Issue 23, 2314002 (2022)

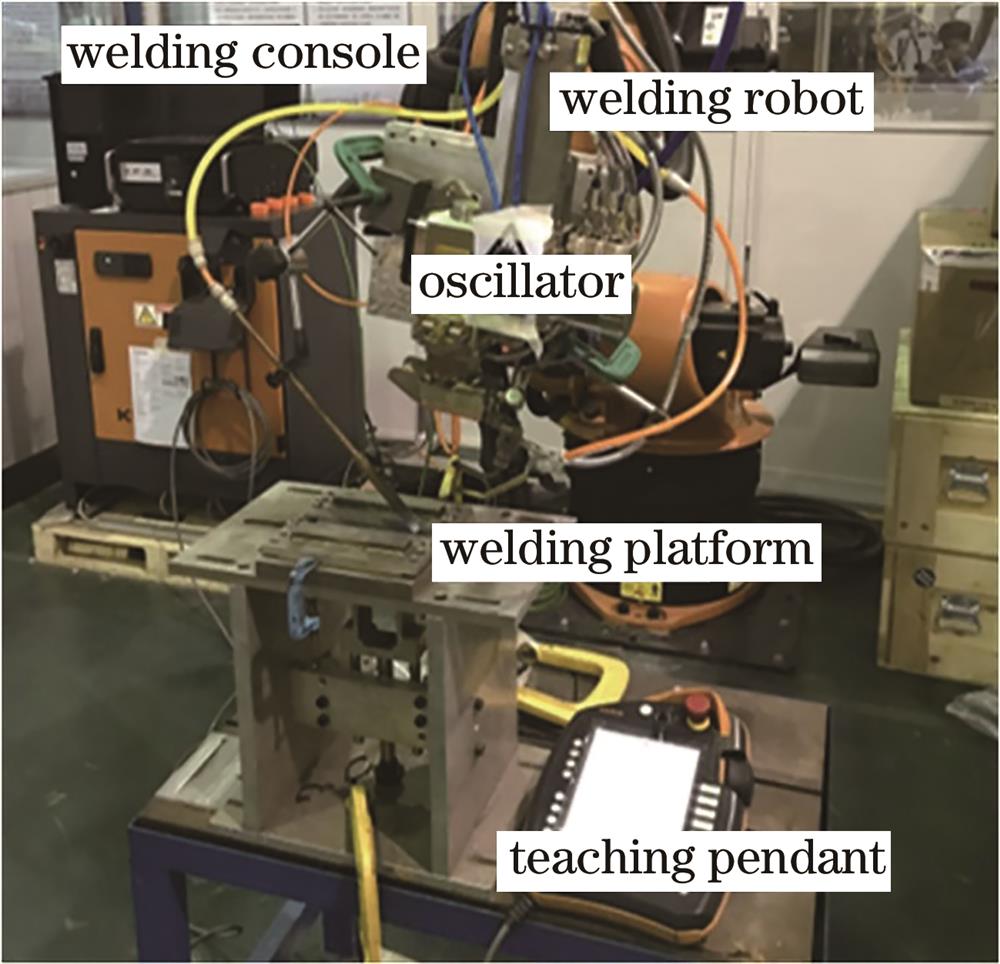

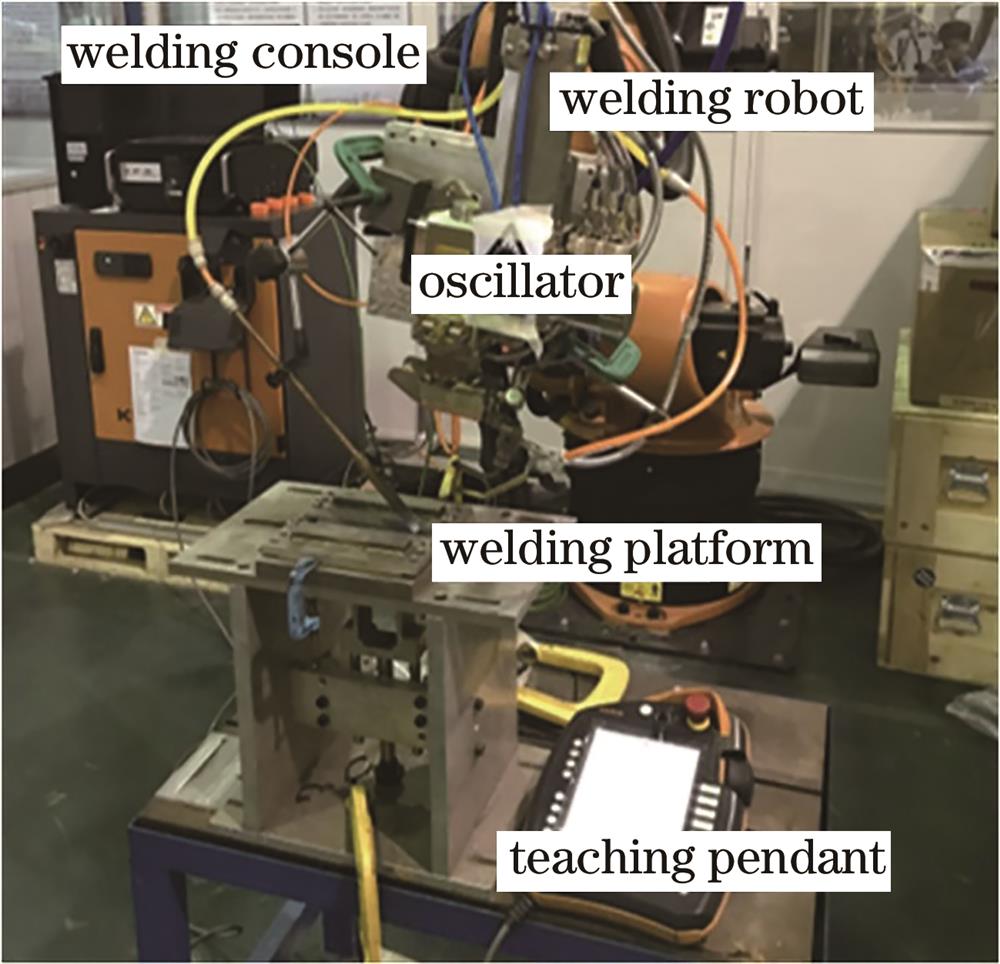

Fig. 1. Test platform of oscillating laser welding

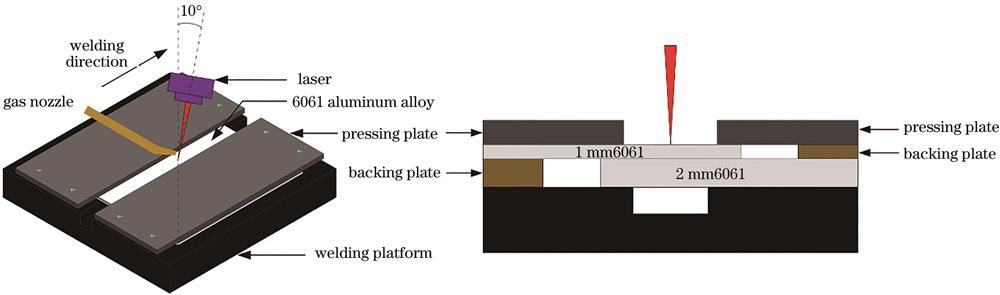

Fig. 2. Schematic diagram of oscillating laser welding lap joint

Fig. 3. Schematic. (a) Tensile specimen; (b) welded joint

Fig. 4. Prediction accuracy of MOGP model. (a) Depth; (b) weld width of lap surface; (c) maximum bearing capacity; (d) carbon emission

Fig. 5. Pareto set obtained by NSGA-II

Fig. 6. Tensile test results of welded joints with optimized process parameters

Fig. 7. Weld surface morphology. (a) After optimization; (b) before optimization

Fig. 8. Microstructure at fusion line of optimized process parameters

Fig. 9. Joint hardness distributions before and after optimization of process parameters. (a) Horizontal hardness distribution; (b) vertical hardness distribution

Fig. 10. Test results of maximum joint bearing capacity

Fig. 11. Carbon emission content test results of welding process

Fig. 12. Contribution of welding process parameters on different welding results. (a) Depth; (b) weld width of lap surface; (c) maximum bearing capacity; (d) carbon emission

|

Table 1. Chemical composition of 6061 aluminum alloy for experiment

|

Table 2. Mechanical properties of 6061 aluminum alloy for experiment

|

Table 3. Sample point data of weld morphology size, maximum joint bearing capacity, and carbon emission

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 4. Relative error results of optimal process parameter combination

Set citation alerts for the article

Please enter your email address