[1] Conde A, Colaço R, Vilar R et al. Corrosion 6c-haviour of steels after laser surface melting[J]. Materials & Design, 21, 441-445(2013).

[2] Zhang Y, Huang Y P. Finite element simulation and parameter optimization of laser rust removal technology for marine steel plate[J]. Applied Laser, 40, 294-299(2020).

[3] Zhang R N, Wei P Y, Jiang Z et al. Research and application status of laser derusting technology in shipbuilding field[J]. Laser Journal, 42, 1-9(2021).

[4] Wang K J. Study on pulsed laser derusting process of Q235 carbon steel[D](2017).

[5] Lu S Y. Technical study on laser cleaning of rust on steel surface[D](2017).

[6] Zhu M. Study on nanosecond laser cleaning process and surface quality of stainless steel Q345C[D](2020).

[7] Saklakoğlu N, Bolouri A, Irizalp S et al. Effects of shot peening and artificial surface defects on fatigue properties of 50CrV4 steel[J]. The International Journal of Advanced Manufacturing Technology, 112, 2961-2970(2021).

[8] Xiao H B, Du C L, Zhang S L et al. Study on the surface morphology of micro-particles and the oxide layer on silicon carbide crystal using nanosecond green laser cleaning assisted with airflow[J]. Crystals, 12, 1788(2022).

[9] Salimbeni R, Pini R, Siano S. A variable pulse width Nd: YAG laser for conservation[J]. Journal of Cultural Heritage, 4, 72-76(2003).

[10] Korenberg C, Baldwin A. Laser cleaning of iron[M]. Lasers in the conservation of artworks VIII, 123-128(2010).

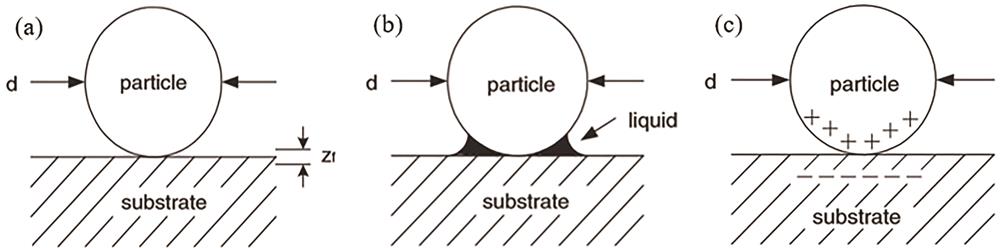

[11] Hsu S C, Lin J. Removal mechanisms of micro-scale particles by surface wave in laser cleaning[J]. Optics & Laser Technology, 38, 544-551(2006).

[12] Luk’yanchuk B S, Arnold N, Huang S M et al. Three-dimensional effects in dry laser cleaning[J]. Applied Physics A, 77, 209-215(2003).

[13] Chen G X, Kwee T J, Tan K P et al. High-power fibre laser cleaning for green shipbuilding[J]. Journal of Laser Micro, 7, 249-253(2012).

[14] Choubey A, Vishwakarma S C, Vachhani D M et al. Study and development of 22 kW peak power fiber coupled short pulse Nd∶YAG laser for cleaning applications[J]. Optics and Lasers in Engineering, 62, 69-79(2014).

[15] Yang M K, Zhou F R, Ma Y et al. Laser derusting technology and its application[J]. Cleaning World, 34, 37-42(2018).

[16] Xu C Y, Xu X K. Mechanism and technology of laser cleaning of ultra-smooth optical substrate surface[J]. Journal of Northwestern Polytechnical University, 128-131(2002).

[17] Tian B. Theoretical model and experimental study on dry laser cleaning[D](2008).

[18] Tong Y Q. Study on mechanism and application fundamentals of laser removal of metal oxides[D](2014).

[19] Li W. Research on mechanisms of laser rust removal and manufacture of laser cleaning devices[D](2014).

[20] Ren Z G, Wu C Z, Chen H N et al. Mechanism of laser derusting and surface properties of low carbon steel[J]. Opto-Electronic Engineering, 44, 1210-1216, 1246(2017).

[21] Yu H Y, Zhang Q M, Chen X et al. Three-dimensional direct laser writing of biomimetic neuron interfaces in the era of artificial intelligence: principles, materials, and applications[J]. Advanced Photonics, 4, 034002(2022).

[22] Yan J W, Huang N S, Deng H X et al. First observation of laser-beam interaction in a dipole magnet[J]. Advanced Photonics, 3, 045003(2021).

[23] Wei J C, Li P, Yu L P et al. Mode-locked fiber laser of 3.5 µm using a single-walled carbon nanotube saturable absorber mirror[J]. Chinese Optics Letters, 20, 011404(2022).

[24] Li H Y, Yang F, Guo J W et al. Development status and prospect of laser cleaning[J]. Laser Technology, 45, 654-661(2021).

[25] Yu X C. Development of laser cleaning equipment based on pulse solid-state laser[D](2018).

[26] Zhu X R, Wang X R[M]. Corrosion and protection of metals in marine environment(1999).

[27] de la Fuente D, Alcántara J, Chico B et al. Characterisation of rust surfaces formed on mild steel exposed to marine atmospheres using XRD and SEM/Micro-Raman techniques[J]. Corrosion Science, 110, 253-264(2016).

[28] Lei Z L, Sun H R, Chen Y B et al. Elimination of rusting layer from high-strength steel surface using different laser cleaning methods[J]. Chinese Journal of Lasers, 46, 0702003(2019).

[29] Koh Y S, Powell J, Kaplan A et al. Laser cleaning of corroded steel surfaces: a comparison with mechanical cleaning methods[M]. Nimmrichter J, Kautek W, Schreiner M. Lasers in the conservation of artworks. Springer proceedings in physics, 116, 13-20(2007).

[30] Zapka W, Ziemlich W, Leung W P et al. “Laser cleaning” removes particles from surfaces[J]. Microelectronic Engineering, 20, 171-183(1993).

[31] Zapka W[M]. The road to ‘steam laser cleaning’, 23-48(2002).

[32] Chen G X, Kwee T J, Tan K P et al. Laser cleaning of steel for paint removal[J]. Applied Physics A, 101, 249-253(2010).

[33] D’Addona D M, Genna S, Giordano A et al. Laser ablation of primer during the welding process of iron plate for shipbuilding industry[J]. Procedia CIRP, 33, 464-469(2015).

[34] Zhang G X, Hua X M, Li F et al. Research and application status of laser de-rusting and de-painting[J]. Hot Working Technology, 48, 1-4, 8(2019).

[35] Brygo F, Dutouquet C, Le Guern F et al. Laser fluence, repetition rate and pulse duration effects on paint ablation[J]. Applied Surface Science, 252, 2131-2138(2006).

[36] Qiu Z B, Zhu H H. Process parameter study on the removing rust using pulsed laser[J]. Applied Laser, 33, 416-420(2013).

[37] Shen Q, Tong Y Q, Ma G D et al. Study on surface roughness of the substrate after laser derusting[J]. Laser & Infrared, 44, 605-608(2014).

[38] Yu H B, Wang C M, Wang J et al. Research on the laser de-rusting of carbon steel surface[J]. Applied Laser, 34, 310-314(2014).

[39] Jasim H A, Demir A G, Previtali B et al. Process development and monitoring in stripping of a highly transparent polymeric paint with ns-pulsed fiber laser[J]. Optics & Laser Technology, 93, 60-66(2017).

[40] Zhang J, Wang Y N, Cheng P et al. Effect of pulsing parameters on laser ablative cleaning of copper oxides[J]. Journal of Applied Physics, 99, 064902(2006).

[41] Song F, Liu S J, Niu K Z et al. Principle and application research on laser cleaning[J]. Cleaning World, 21, 1-6(2005).

[42] Li H T, Zhou J Z, Sun Q et al. Electrochemical corrosion properties of AH32 steel via laser cleaning[J]. Laser & Optoelectronics Progress, 56, 211403(2019).

[43] Lu Y F, Song W D, Hong M H et al. Mechanism of and method to avoid discoloration of stainless steel surfaces in laser cleaning[J]. Applied Physics A, 64, 573-578(1997).

[44] Yang M K, Zhou F R, Ma Y et al. Laser rust removing process of deep rusting steel plate[J]. Applied Laser, 38, 975-980(2018).

[45] Zhao M L, Liu T G, Jiang J F et al. Effect of defocusing distance on the contaminated surface of brass ring with nanosecond laser in a 3D laser scanning system[J]. Optics and Lasers in Engineering, 59, 11-18(2014).

[46] Zhang X, Wang M D, Liu J C et al. Laser intelligent rust removal based on machine vision[J]. Laser & Optoelectronics Progress, 58, 0814001(2021).

[47] Saravanan D. Machine vision for detection contaminations technique of cotton[J]. Man-Made Textiles in India, X7, 409-413(2019).

[48] Shi T Y, Zhou L Z, Wang C M et al. Machine vision-based real-time monitor system for laser cleaning aluminum alloy[J]. Chinese Journal of Lasers, 46, 0402007(2019).

[49] Ding Y, Xue Y, Pang J H et al. Advances in in situ monitoring technology for laser processing[J]. Scientia Sinica: Physica, Mechanica & Astronomica, 49, 60-78(2019).

[50] He B, Jiang W, Fan Z Y et al. Application of rust-removing laser in marine engineering construction[J]. Coating and Protection, 41, 40-45(2020).

[51] Tong Y Q, Zhang Y K, Yao H B et al. Real-time monitoring system for laser derusting based on plasma intensity[J]. Chinese Journal of Lasers, 38, 1003009(2011).

[52] Lee J M, Steen W M. In-process surface monitoring for laser cleaning processes using a chromatic modulation technique[J]. The International Journal of Advanced Manufacturing Technology, 17, 281-287(2001).

[53] Moretti P, Iwanicka M, Melessanaki K et al. Laser cleaning of paintings: in situ optimization of operative parameters through non-invasive assessment by optical coherence tomography (OCT), reflection FT-IR spectroscopy and laser induced fluorescence spectroscopy (LIF)[J]. Heritage Science, 7, 1-12(2019).

[54] Tserevelakis G J, Pouli P, Zacharakis G. Listening to laser light interactions with objects of art: a novel photoacoustic approach for diagnosis and monitoring of laser cleaning interventions[J]. Heritage Science, 8, 6-98(2020).

[55] Sun L X, Wang W J, Qi L F et al. Online monitoring of laser cleaning effect of carbon fiber composite materials based on laser-induced breakdown spectroscopy technology[J]. Chinese Journal of Lasers, 47, 1111003(2020).