Hanwang Zhu, Xiangyao Xue, Mingzhen Shao, Wenbao Zhang, Shang Li, Xiushuo Wang, Guangyi Wang, Xinyu Yang. Design and optimization of a single-core axis in a ground-based photoelectric imaging system[J]. Infrared and Laser Engineering, 2024, 53(3): 20230629

Search by keywords or author

- Infrared and Laser Engineering

- Vol. 53, Issue 3, 20230629 (2024)

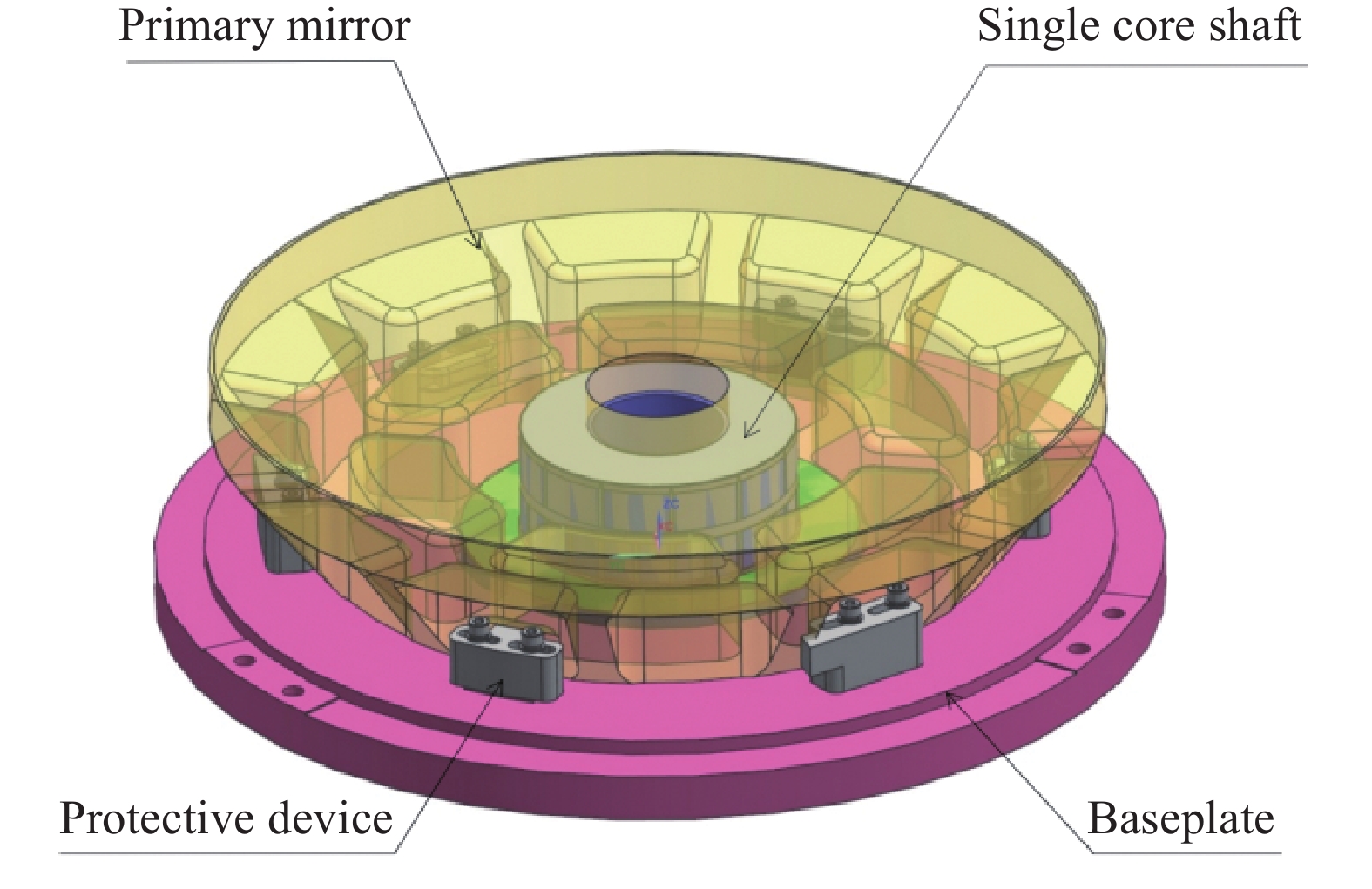

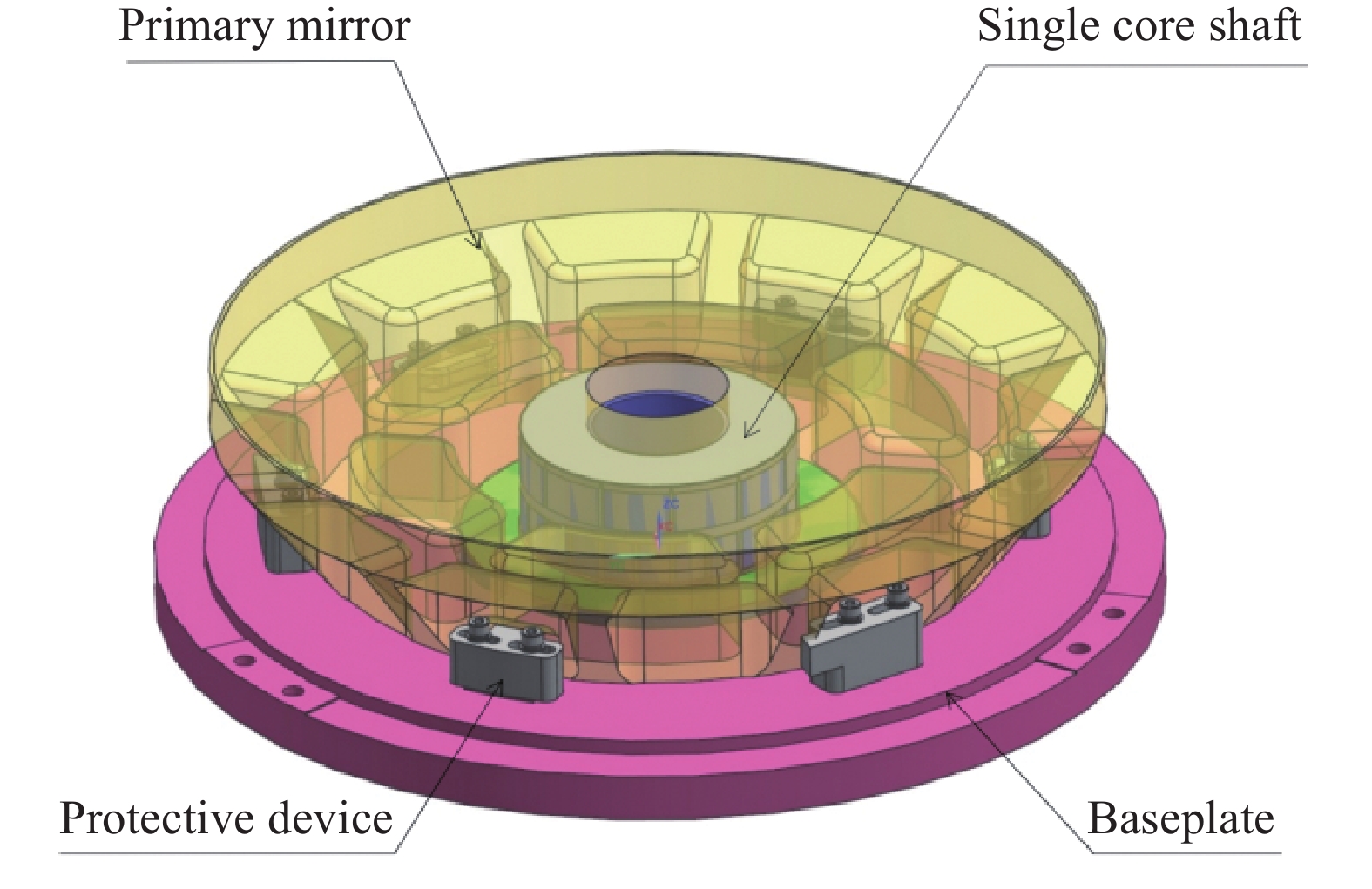

Fig. 1. Main system structural composition

Fig. 2. Schematic diagram of supporting structure parameters

Fig. 3. Schematic diagram of support structure diagram

Fig. 4. Relationship between C 11, a , b and c

Fig. 5. Structure of MISA

Fig. 6. Workflow chart of Isight integration platform

Fig. 7. Iterative processes of MIGA

Fig. 8. Pareto front analysis of parameter relationships

Fig. 9. Deformation cloud map of the primary mirror under thermal field

Fig. 10. Deformation cloud map of the primary mirror under gravitational field

Fig. 11. Overall comparison of surface shape errors before and after optimization under different temperature changes. (a) ΔT =20 ℃ (from +20 ℃ to +40 ℃); (b) ΔT =80 ℃ (from −40 ℃ to +40 ℃)

Fig. 12. The primary mirror is placed in a horizontal position along the optical axis

Fig. 13. Analysis of main mirror surface accuracy using interferometry. (a) Detection at 20 ℃; (b) Detection at 40 ℃

|

Table 1. Properties of the material mechanics

|

Table 2. MIGA parameter setting

|

Table 3. Comparison before and after optimization

|

Table 4. Each working state error of the primary mirror

Set citation alerts for the article

Please enter your email address