Xiaodong Wang, Songyu Hu. Continuous smart light source controller design for laser structure light measurement[J]. Infrared and Laser Engineering, 2021, 50(3): 20200180

Search by keywords or author

- Infrared and Laser Engineering

- Vol. 50, Issue 3, 20200180 (2021)

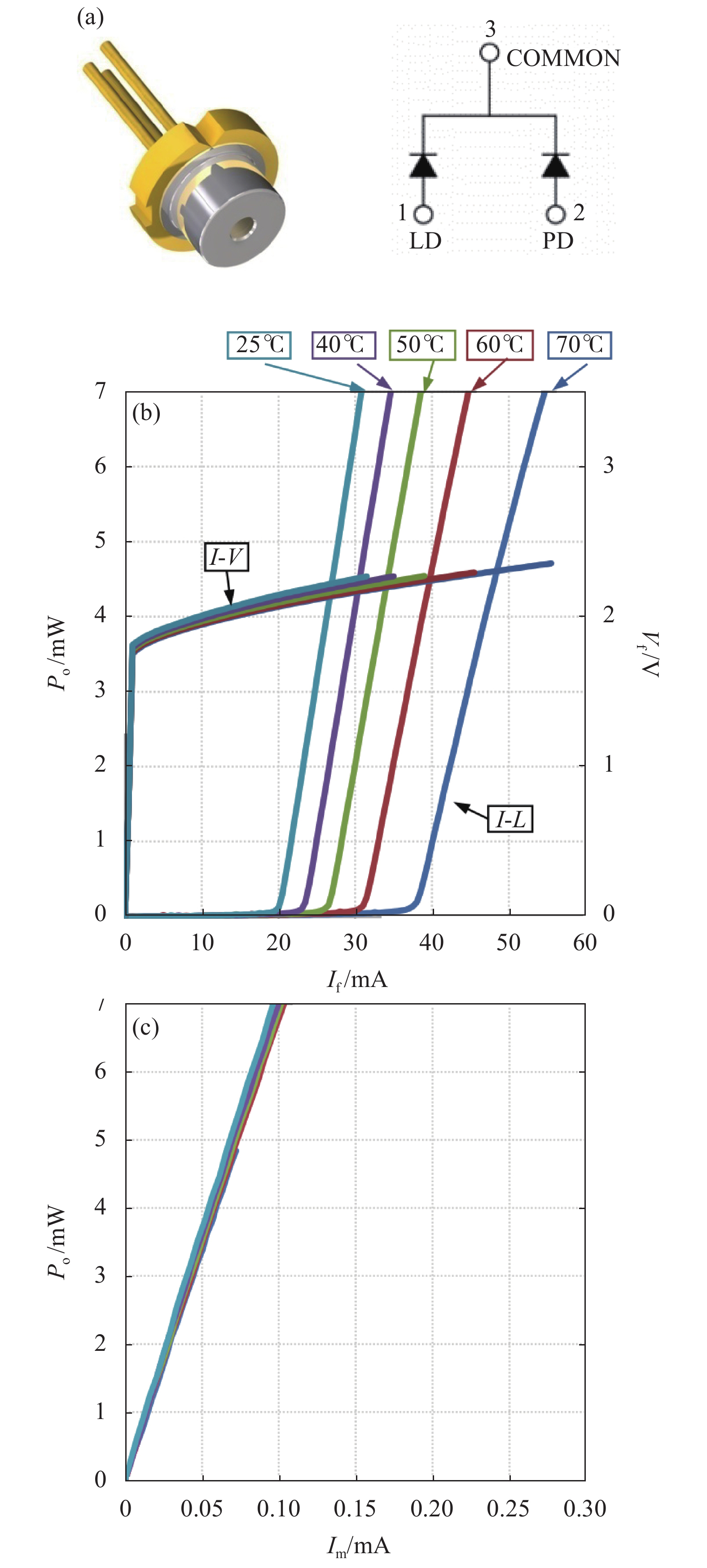

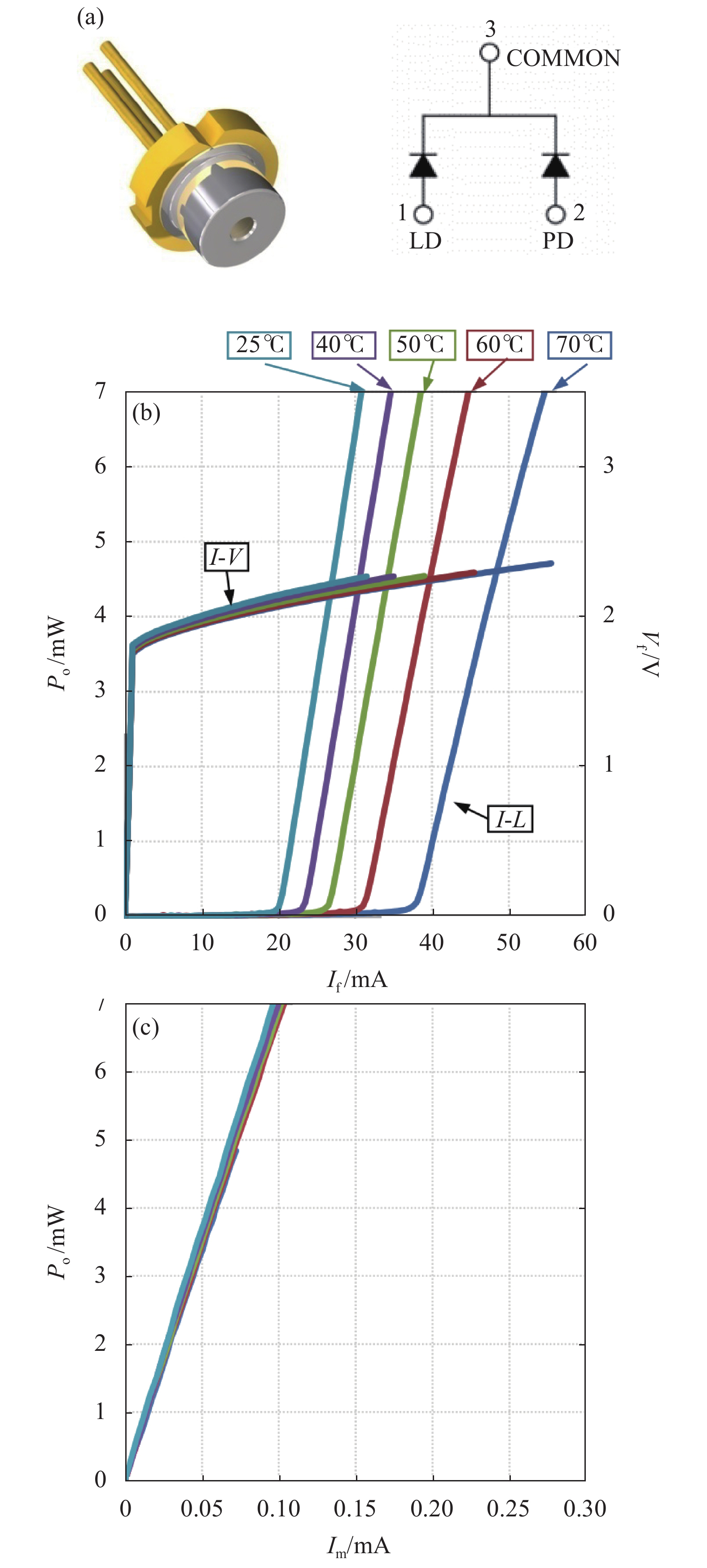

Fig. 1. The laser diode electrical feature definition. (a) Laser diode pin map; (b) V -I feature of LD; (c) Electrical feature of PD

Fig. 2. Architecture diagram of laser structure light controller

Fig. 3. Diagram of four PWM signals principle with STM32 MCU advanced timer TIM1

Fig. 4. Laser diode driver circuit diagram of by PWM signal of STM32

Fig. 5. PWM pulse wave parameters diagram

Fig. 6. Laser diode relationship curve of PWM ratio and circuit current

Fig. 7. Laser images analysis data diagrams of different PWM ratio laser output. (a) Image of 46.29% ratio, 21.43 mA laser current; (b) Gray horizontal distribution chart of (a); (c) Image of 75.59% ratio, 55.9 mA laser current; (d) Gray horizontal distribution chart of (b)

Fig. 8. Diagrams of imaging analysis for laser controller. (a) Hybrid material surface laser projection image (21 mA); (b) Hybrid material surface laser projection image (55 mA); (c) Package platform laser projection image (21 mA); (d) Package platform laser projection image (55 mA); (e) Light spot number ( Serials1 is (c), and Serials2 is (d) Laser Images) (f) Measurement error (( Serials1 , Serials2 is the error of (c) , (d))

| ||||||||||||||||||||||||||||||||||||||

Table 1. [in Chinese]

Set citation alerts for the article

Please enter your email address