Weiming WANG, Weide WANG, Yi SU, Qingsong MA, Dongxu YAO, Yuping ZENG. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 39, Issue 6, 634 (2024)

![Schematic of typical packaging of power semiconductor device[1]](/richHtml/jim/2024/39/6/634/img_1.png)

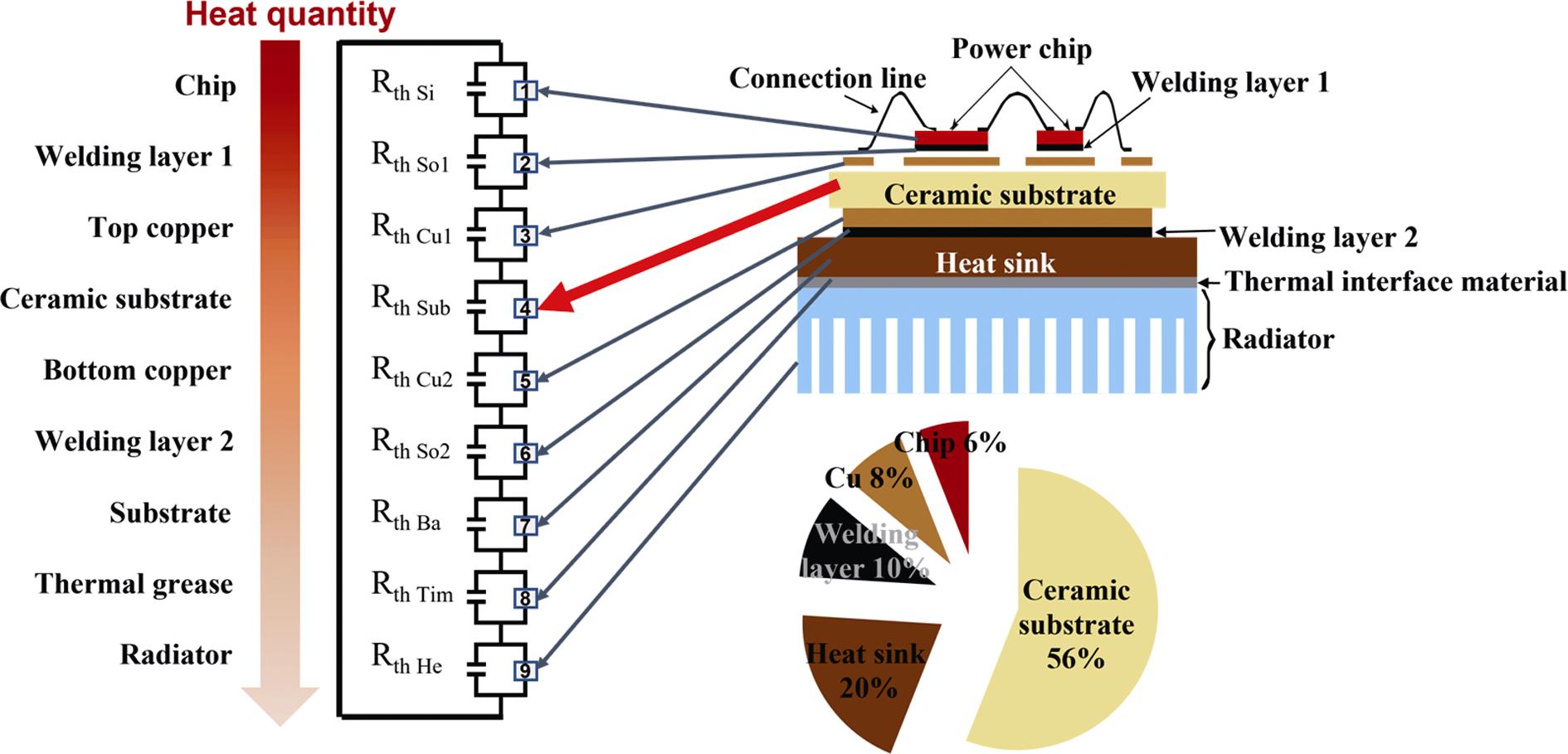

1. Schematic of typical packaging of power semiconductor device[1]

![Schematic of the liquid phase sintering mechanism for Si3N4 ceramics[10]](/richHtml/jim/2024/39/6/634/img_2.png)

2. Schematic of the liquid phase sintering mechanism for Si3N4 ceramics[10]

3. Effects of volume fraction of glassy phase, grain- boundary film thickness(δ ), and grain size on the thermal conductivity of β -Si3N4[13]

4. Effect of lattice oxygen content on the thermal conductivity of Si3N4 ceramics[17]

5. Displacement-temperature curves of Si3N4 ceramics with MgF2 or MgO as sintering additives[19]

6. XRD patterns of Si3N4 samples prepared with different LiF contents[20]

7. Depolymerization mechanism of F atom in silicate melts[22]

8. SEM morphologies of the polished surfaces of Si3N4 ceramics after gas pressure sintering (GPS) with different additives added[24]

9. Typical HRTEM images of Si3N4 ceramics added with Y2O3 (a) and Y2Si4N6C (b) as additives[31]

10. Curves of relative displacement of the as-pressed specimens with temperature variation[32]

11. Densification mechanism of Si3N4 ceramics with ZrSi2-MgO additive[36]

12. Shrinkage curves of the Si3N4 ceramics[10]

13. Schematic illustration of Si3N4-Y2O3-SiO2 phase at 1900 ℃[10]

14. STEM-EDS characterizations of Si3N4 ceramics with the addition of ZrO2 and ZrH2[47]

15. SEM images on the fracture surfaces of nitrided samples (a, b) and post-sintered samples (c, d) without (a, c) and with (b, d) graphite powder bed addition[57]

17. (a) Shrinkage behaviors and densification mechanism of Si3N4 ceramics during sintering, and (b) relationship between β phase ratio and relative density[62]

18. Evolution of microstructure and diameter of Si3N4 ceramics[10]

|

Table 1. Properties of ceramic substrate materials[2]

Set citation alerts for the article

Please enter your email address