Guangfeng Yang, Feng Gao, Jing Cui, Anyuan Xue. Effect of scanning speed on microstructure and properties of 300M steel cladding C276 coating[J]. Infrared and Laser Engineering, 2023, 52(1): 20220328

Search by keywords or author

- Infrared and Laser Engineering

- Vol. 52, Issue 1, 20220328 (2023)

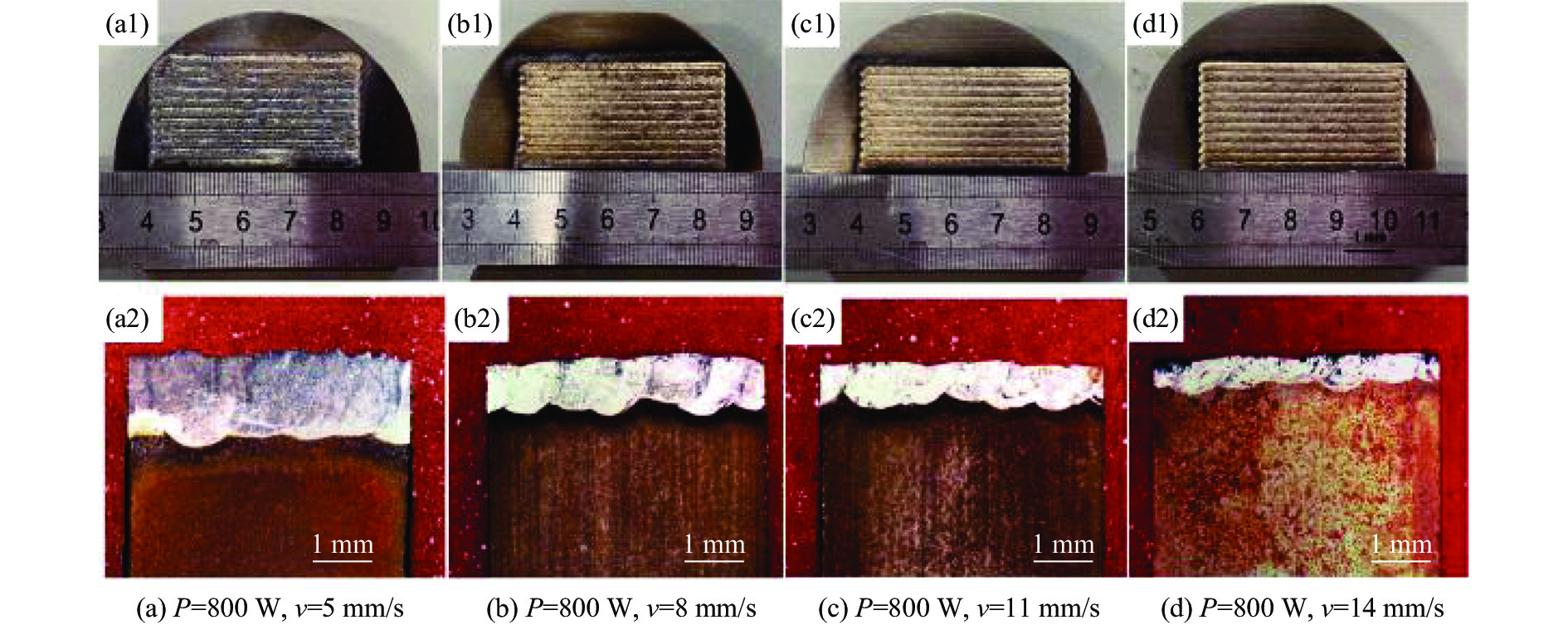

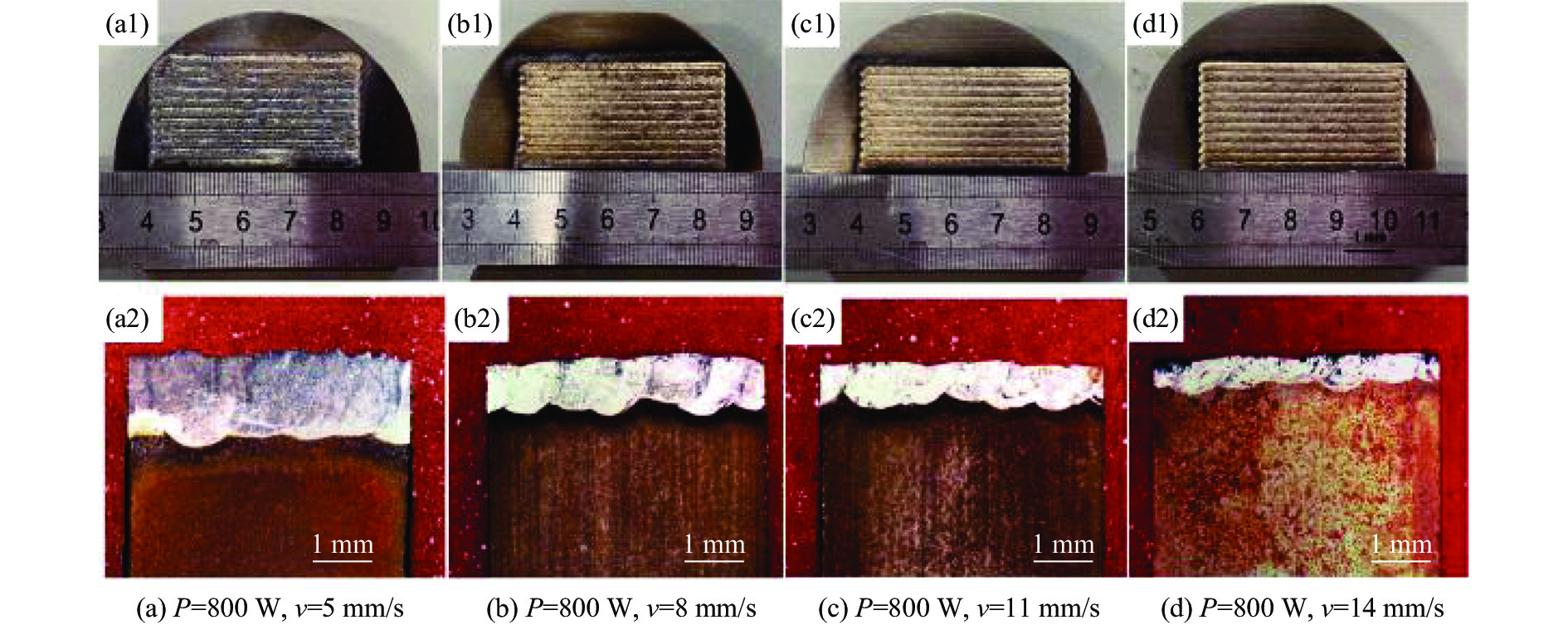

Fig. 1. Macroface topography of the coated front and cross section. (a1)-(d1) Front shape;(a2)-(d2) Cross section shape

Fig. 2. XRD diffraction pattern

Fig. 3. Grain structure distribution of laser cladding single and multi-channel forming. (a) Single channel grain structure distribution; (b) Multi-channel grain structure distribution

Fig. 4. Microscopic tissue topography of the central area of the C276 coating. (a1)-(d1) Coating and substrate handover zone; (a2)-(d2) Coating in the middle; (a3)-(d3) Coating top

Fig. 5. Microtissue topography of the C276 coating lap area. (a1)-(d1) Coating and substrate handover zone; (a2)-(d2) Coating in the middle; (a3)-(d3) Coating top

Fig. 6. Distribution diagram of EDS element. (a) EDS element distribution at the junction of coating and matrix; (b) Distribution of EDS elements at coating lap

Fig. 7. Microhardness of the coating center area and lap area. (a) Central zone; (b) Lapping area

Fig. 8. Friction coefficient curves of 300M steel and coating

Fig. 9. Weight loss and wear rate of 300M steel and coating test piece

Fig. 10. 300M steel and coating electrochemical curves. (a) Polarization curves; (b) Nyquist graph

|

Table 1. Chemical composition of 300M steel (wt%)

|

Table 2. Chemical composition of Hastelloy C276 (wt%)

|

Table 3. Polarization curve fitting results

Set citation alerts for the article

Please enter your email address