Zijian Huang, Yang Li, Yongqiang Yang, Yilong Zhang. Forming Quality and Defects of Sn-Ag-Cu Alloy by Selective Laser Melting in Air Environment[J]. Laser & Optoelectronics Progress, 2025, 62(3): 0314003

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 62, Issue 3, 0314003 (2025)

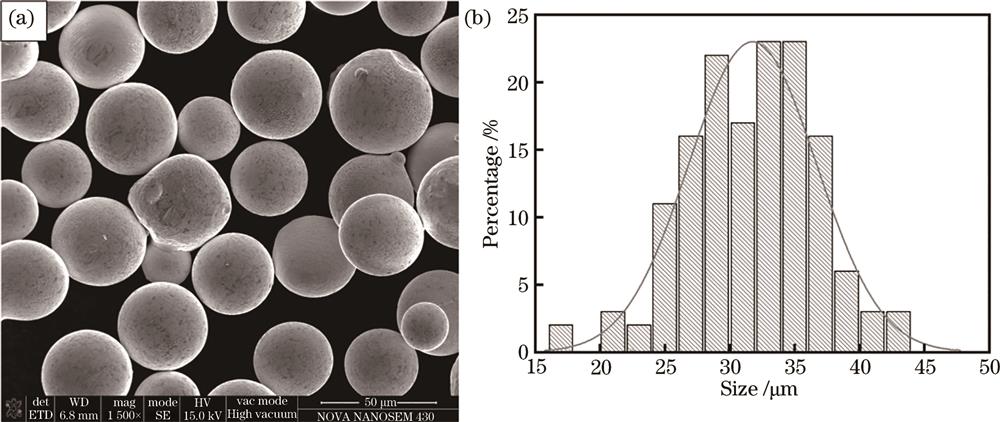

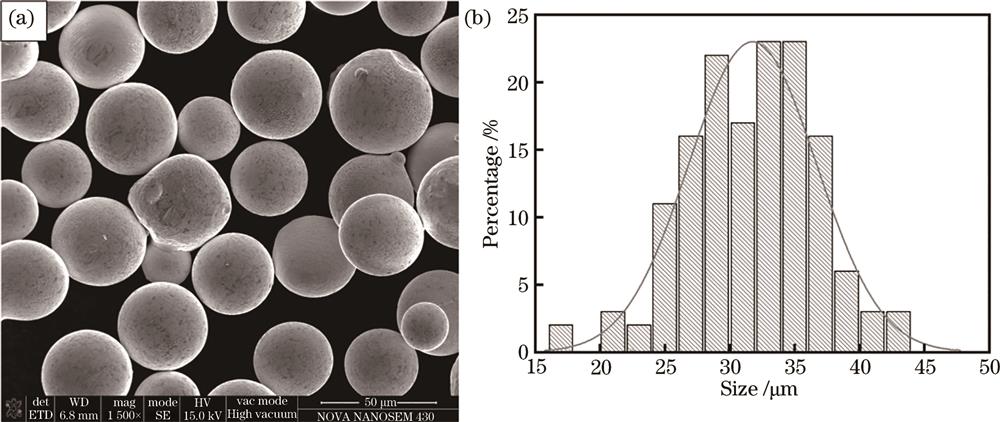

Fig. 1. Sn-3.0Ag-0.5Cu powder morphology and size distribution. (a) Powder morphology; (b) size distribution

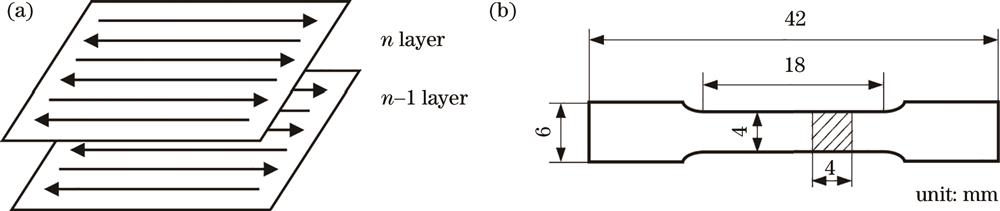

Fig. 2. Schematic of scanning strategy and tensile sample. (a) Scanning strategy; (b) tensile sample

Fig. 3. Sn-3.0Ag-0.5Cu forming samples

Fig. 4. Changes in density and various factors

Fig. 5. Energy density- density relationship of forming samples

Fig. 6. Top-surface morphologies at different process parameters. (a) 20 W-1000 mm/s-0.09 mm; (b) 20 W-800 mm/s-0.07 mm; (c) 30 W-600 mm/s-0.07 mm; (d) 35 W-900 mm/s-0.06 mm; (e) 40 W-900 mm/s-0.07 mm; (f) 40 W-700 mm/s-0.05 mm

Fig. 7. Microscope morphologies at different process parameters. (a) 20 W-1000 mm/s-0.09 mm; (b) 20 W-800 mm/s-0.07 mm; (c) 30 W-600 mm/s-0.07 mm; (d) 35 W-900 mm/s-0.06 mm; (e) 40 W-900 mm/s-0.07 mm; (f) 40 W-700 mm/s-0.05 mm

Fig. 8. Tensile properties at different powers. (a) Stress-strain curves; (b) tensile strength and elongation

Fig. 9. Fracture morphologies at different Laser powers. (a) 25 W; (b) 30 W; (c) 35 W; (d) 40 W

Fig. 10. Surface and internal morphology of samples in different environments. (a) Surface morphology with protective atmosphere; (b) surface morphology without protective atmosphere; (c) internal morphology with protective atmosphere; (d) internal morphology without protective atmosphere

Fig. 11. XRD patterns of samples in different environments

Fig. 12. SEM images of samples in different environments. (a) With protective atmosphere; (b) without protective atmosphere

Fig. 13. EDS images of samples in different environments. (a) With protective atmosphere; (b) without protective atmosphere

Fig. 14. Mechanism of spatter generation

Fig. 15. Spatter generation and residue during the forming process. (a) Spatter generation; (b) spatter residue after paving

Fig. 16. SEM image of top surface of sample in air atmosphere

Fig. 17. Influence of spatter on forming and paving. (a) Paving of the first layer; (b) residue of spatter; (c) non-fusion powder caused by spatter; (d) spatter effects on paving roller

|

Table 1. Chemical composition of Sn-3.0Ag-0.5Cu powder

|

Table 2. Factor level table

|

Table 3. Density test results

|

Table 4. Range analysis result of density

|

Table 5. Density and mechanical properties of samples in different environments

Set citation alerts for the article

Please enter your email address