[1] Jia H L, Sun H, Wang H Z et al. Scanning strategy in selective laser melting (SLM): a review[J]. The International Journal of Advanced Manufacturing Technology, 113, 2413-2435(2021).

[2] Zhao Y Z, Dong Z, Wang D et al. Anisotropy in microstructure and mechanical properties of pure zinc fabricated by laser additive manufacturing (invited)[J]. Chinese Journal of Lasers, 51, 0402301(2024).

[3] Dejene N D, Lemu H G. Current status and challenges of powder bed fusion-based metal additive manufacturing: literature review[J]. Metals, 13, 424(2023).

[4] Hu W N, Feng Y, Wang D et al. Method and process of selective laser melting forming low‐angle support‐free structures (invited)[J]. Chinese Journal of Lasers, 51, 0402303(2024).

[5] Wang Y, Tan Q T, Pu F et al. A review of the application of additive manufacturing in prosthetic and orthotic clinics from a biomechanical perspective[J]. Engineering, 6, 1258-1266(2020).

[6] Ma Y, Guan Y C. Research and application progress in laser additive manufacturing of heterogeneous metals (invited)[J]. Chinese Journal of Lasers, 51, 1002304(2024).

[7] Kumar V, Pruncu C I, Wang Y P et al. The response of 316 L steel manufactured by selective laser melting route to high-temperature oxidation behaviour: the role of microstructure modification[J]. Materials Characterization, 207, 113531(2024).

[8] Texier D, Copin E, Flores A et al. High temperature oxidation of NiCrAlY coated alloy 625 manufactured by selective laser melting[J]. Surface and Coatings Technology, 398, 126041(2020).

[9] Pauzon C, Dietrich K, Forêt P et al. Control of residual oxygen of the process atmosphere during laser-powder bed fusion processing of Ti-6Al-4V[J]. Additive Manufacturing, 38, 101765(2021).

[10] Hu Z H, Zhu H H, Nie X J et al. On the role of atmospheric oxygen into mechanical properties and fracture behavior of selective laser melted AlCu5MnCdVA[J]. Materials & Design, 150, 18-27(2018).

[11] Dietrich K, Diller J, Dubiez-Le Goff S et al. The influence of oxygen on the chemical composition and mechanical properties of Ti-6Al-4V during laser powder bed fusion (L-PBF)[J]. Additive Manufacturing, 32, 100980(2020).

[12] Li R D, Liu J H, Shi Y S et al. Balling behavior of stainless steel and nickel powder during selective laser melting process[J]. The International Journal of Advanced Manufacturing Technology, 59, 1025-1035(2012).

[13] Zhou X, An Z B, Shen Z J et al. Particles control in selective laser melting in situ oxide dispersion strengthened method[J]. IOP Conference Series: Materials Science and Engineering, 167, 012048(2017).

[14] Iveković A, Omidvari N, Vrancken B et al. Selective laser melting of tungsten and tungsten alloys[J]. International Journal of Refractory Metals and Hard Materials, 72, 27-32(2018).

[15] Chantaramanee S, Sungkhaphaitoon P. Combined effects of Bi and Sb elements on microstructure, thermal and mechanical properties of Sn-0.7Ag-0.5Cu solder alloys[J]. Transactions of Nonferrous Metals Society of China, 32, 3301-3311(2022).

[16] Zhang L, Sun L, Guo Y H et al. Properties of SnAgCu solders bearing Al nanoparticles[C], 195-197(2015).

[17] Tian S, Wang F J, He P et al. Effect of reflowing atmosphere on mechanical properties of Sn-3.0Ag-0.5Cu Pb-free solder joints[J]. Electronics Process Technology, 36, 311-314(2015).

[18] Liang H X, Tang Y S, Yang W Y et al. Study on oxidation behavior of SnCu and SnAgCu series lead-free solder[J]. Hot Working Technology, 52, 118-120, 127(2023).

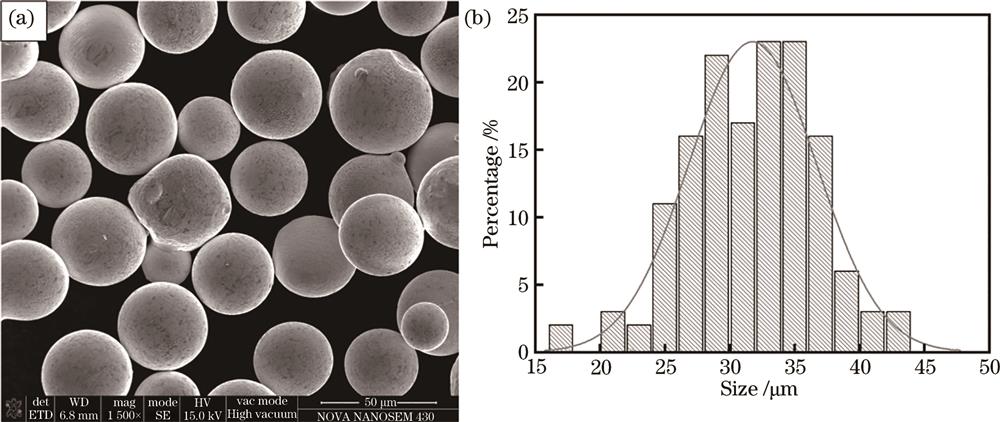

[19] Yu J M, Yang Y Q, Trofimov V et al. Laser powder bed fusion fabrication of Sn‑3.0Ag‑0.5Cu (SAC305) alloys without protective atmosphere: process and mechanical properties[J]. Chinese Journal of Lasers, 50, 2402303(2023).

[20] Zhao Y S, Ding C G, Chen H et al. Study on SLM forming process, residual stress and thermal fatigue of 24CrNiMo alloy steel[J]. Materials, 14, 4383(2021).

[21] Yang J J, Han J, Yu H C et al. Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6Al-4V alloy[J]. Materials & Design, 110, 558-570(2016).

[22] Cong J Q, Ji Y P, Wang L et al. Research progress on defects and forming mechanisms of selective laser melting formed 316L stainless steel parts[J]. Materials for Mechanical Engineering, 47, 1-6(2023).

[23] Hua W J, Zhang J X. Defect and quality control of GH3536 super alloy fabricated via laser selective melting[J]. Laser & Optoelectronics Progress, 61, 0514008(2024).

[24] Wang D, Wu S B, Fu F et al. Mechanisms and characteristics of spatter generation in SLM processing and its effect on the properties[J]. Materials & Design, 117, 121-130(2017).

[25] Chen X Y, Wei H L, Liu T T et al. In‑situ monitoring and diagnostics for deposition defects in laser powder bed fusion process based on optical signals of melt pool (invited)[J]. Chinese Journal of Lasers, 51, 1002308(2024).

[26] Fan S J, Yang Y Q, Song C H et al. Properties of 316L stainless steel formed by dual-laser selective melting[J]. Chinese Journal of Lasers, 50, 1602305(2023).

[27] Wang B, Li K N, Du X X et al. Effect of oxide membrane on melting of Sn powder particles and properties of Cu-Sn binders[J]. Shanxi Metallurgy, 45, 12-15(2022).