[1] S CHEN, X QIU, B ZHANG et al. Advances in antioxidation coating materials for carbon/carbon composites. Journal of Alloys and Compounds, 161143(2021).

[2] X JIN, X FAN, C LU et al. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. Journal of the European Ceramic Society, 1(2018).

[3] Q FU, P ZHANG, L ZHUANG et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science & Technology, 31(2022).

[5] Y M MANAWI, IHSANULLAH, A SAMARA et al. A review of carbon nanomaterials’ synthesis

[6] L ZHENG, Y WANG, J QIN et al. Scalable manufacturing of carbon nanotubes on continuous carbon fibers surface from chemical vapor deposition. Vacuum, 84(2018).

[7] K A SHAH, B A TALI. Synthesis of carbon nanotubes by catalytic chemical vapour deposition: a review on carbon sources, catalysts and substrates. Materials Science in Semiconductor Processing, 67(2016).

[8] X WEI, L CHENG, L ZHANG et al. Numerical simulation of effect of methyltrichlorosilane flux on isothermal chemical vapor infiltration process of C/SiC composites. Journal of the American Ceramic Society, 2762(2006).

[9] H LI, A LI, R BAI et al. Numerical simulation of chemical vapor infiltration of propylene into C/C composites with reduced multi-step kinetic models. Carbon, 2937(2005).

[10] H G KIM, W JI, H J KWON et al. Full-scale multi-physics numerical analysis of an isothermal chemical vapor infiltration process for manufacturing C/C composites. Carbon, 174(2021).

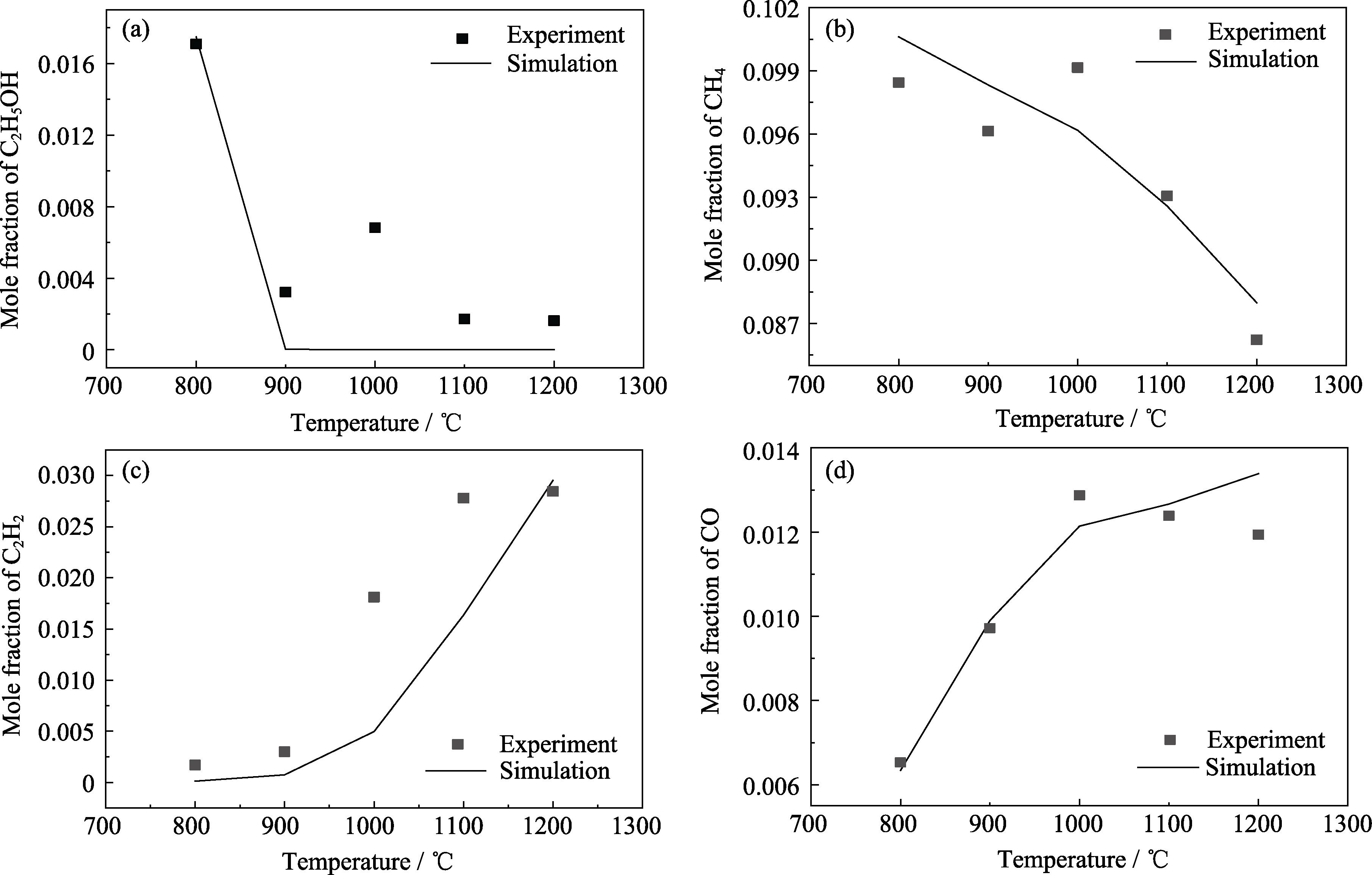

[11] B REN, S ZHANG, L HE et al. Effect of oxygen and hydrogen on microstructure of pyrolytic carbon deposited from thermal decomposition of methane and ethanol. Journal of Solid State Chemistry, 86(2018).

[12] J REN, K LI, S ZHANG et al. Preparation of carbon/carbon composite by pyrolysis of ethanol and methane. Materials & Design, 174(2015).

[13] A LI, S ZHANG, B REZNIK et al. Chemistry and kinetics of chemical vapor deposition of pyrolytic carbon from ethanol. Proceedings of the Combustion Institute, 1843(2011).

[14] A LI, S ZHANG, B REZNIK et al. Synthesis of pyrolytic carbon composites using ethanol as precursor. Industrial & Engineering Chemistry Research, 10421(2010).

[15] N M MARINOV. A detailed chemical kinetic model for high temperature ethanol oxidation. International Journal of Chemical Kinetics, 183(1999).

[16] A V MINAKOV, M M SIMUNIN, I I RYZHKOV. Modelling of ethanol pyrolysis in a commercial CVD reactor for growing carbon layers on alumina substrates. International Journal of Heat and Mass Transfer, 118764(2019).

[17] C HU, H LI, S ZHANG et al. A molecular-level analysis of gas-phase reactions in chemical vapor deposition of carbon from methane using a detailed kinetic model. Journal of Materials Science, 38976(2016).

[18] V M SHINDE, P PRADEEP. Detailed gas-phase kinetics and reduced reaction mechanism for methane pyrolysis involved in CVD/CVI processes. Journal of Analytical and Applied Pyrolysis, 104998(2021).

[19] C W GAO, J W ALLEN, W H GREEN et al. Reaction mechanism generator: automatic construction of chemical kinetic mechanisms. Computer Physics Communications, 212(2016).

[20] C F CURTISS, J O HIRSCHFELDER. Integration of stiff equations. Proceedings of the National Academy of Sciences, 235(1952).

[21] S W BENSON, J H BUSS. Additivity rules for the estimation of molecular properties. Thermodynamic properties. Journal of Chemical Physics, 546(1958).

[22] S W BENSON. Thermochemical kinetics:methods for the estimation of thermochemical data and rate parameters(1976).

[23] H HASHEMI, J M CHRISTENSEN, P GLARBORG. High- pressure pyrolysis and oxidation of ethanol. Fuel, 247(2018).

[24] R G SUSNOW, A M DEAN, W H GREEN et al. Rate-based construction of kinetic models for complex systems. Journal of Physical Chemistry A, 3731(1997).

[25] M LIU, D A GRINBERG, M S JOHNSON et al. Reaction mechanism generator v3.0: advances in automatic mechanism generation. Journal of Chemical Information and Modeling, 2686(2021).

[26] Q HUANG, Y CHEN, Z BAO et al. PFR model for high-pressure reaction flow of fuel. Combustion Science and Technology, 2268(2022).

[27] A GUPTA, S NIGAM, V M SHINDE. Gas-phase kinetic of boron carbide chemical vapor deposition using BCl3+ CH4+ H2 mixture. Journal of the American Ceramic Society, 3885(2022).

[28] M BRÜGGERT, Z HU, K J HÜTTINGER. Chemistry and kinetics of chemical vapor deposition of pyrocarbon: VI. influence of temperature using methane as a carbon source. Carbon, 2021(1999).