Zhuorui TANG, Chaobin MAO, Yinghuai ZHANG, Chang FENG, Minyan QIU, Cheng HU, Xin ZHANG. CGH compensation surface testing technology for high-order SiC aspherical secondary mirror[J]. Infrared and Laser Engineering, 2025, 54(2): 20240519

Search by keywords or author

- Infrared and Laser Engineering

- Vol. 54, Issue 2, 20240519 (2025)

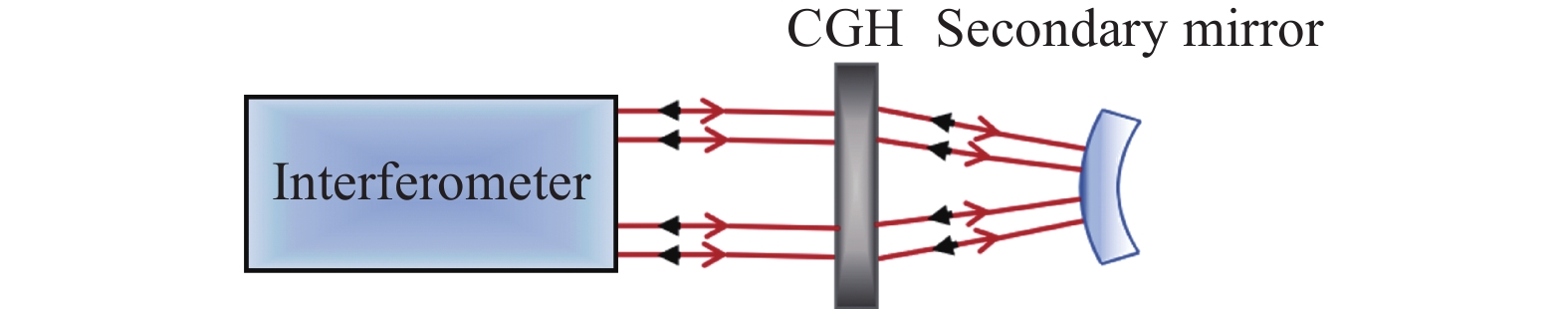

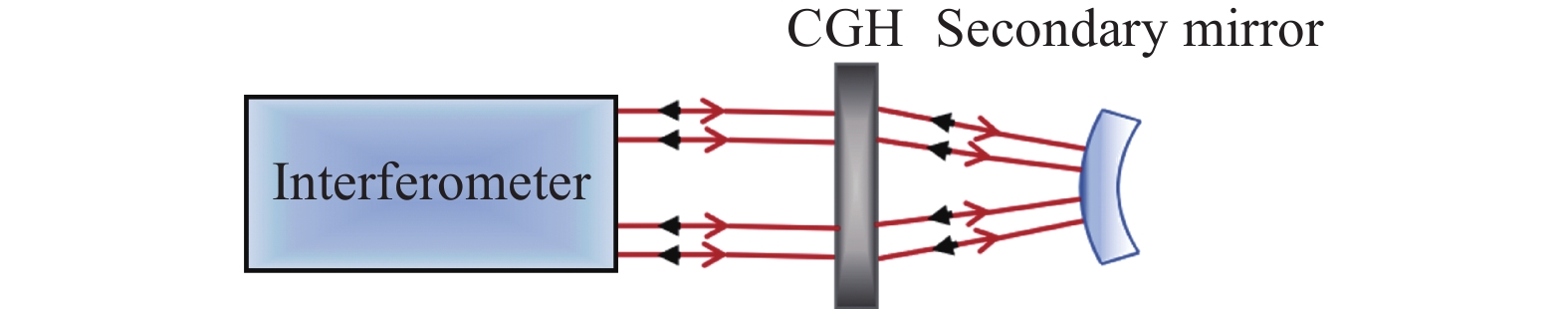

Fig. 1. The optical path diagram of CGH compensation testing of the secondary mirror

Fig. 2. The optical path design diagram of CGH null compensation high-order aspheric secondary mirror

Fig. 3. Design residual of the main area

Fig. 4. Fringe diagram of the main area of CGH designed for high-order aspherical secondary mirror

Fig. 5. Fringe diagram of CGH alignment area of high-order aspherical secondary mirror

Fig. 6. Optical path diagram of the diffraction order separation of the high-order aspherical secondary mirror

Fig. 7. Schematic diagram of the diffraction order separation of high-order aspherical secondary mirror

Fig. 8. Surface map of the high-order aspherical secondary mirror interference detection results

Fig. 9. Surface map of transmission wave aberration detection results of CGH

Fig. 10. CGH substrate error Zernike fitting result

Fig. 11. Surface map of the high-order aspherical secondary mirror interference detection results after calibration

|

Table 1. The basic parameters of the optical path

Set citation alerts for the article

Please enter your email address