[1] Zhang R Z, Li L J, Tang M Q et al. Research progress of laser cladding technology[J]. Heat Treatment Technology and Equipment, 38, 7-11(2017).

[2] Hu D W, Liu Y, Chen H et al. Microstructure and properties of laser cladding Ni-based WC coating on Q960E steel[J]. Chinese Journal of Lasers, 48, 0602120(2021).

[3] Hua C. Application of laser cladding technology[J]. Science and Technology Wind, 146(2019).

[4] Feng Y Q, Du Z X, Hu Z F. Influence of Ni content on microstructure and properties of NiTi alloy coatings fabricated by laser cladding[J]. Chinese Journal of Lasers, 49, 0802022(2022).

[5] Nie J H. Study on the microstructure and high temperature properties of FeCrAlNbNi coating on 304 stainless steel surface by laser cladding[D](2021).

[6] Fang Z X, Qi W J, Li Z Q. Effect of laser cladding lap ratio of 304 stainless steel on microstructure, wear resistance and corrosion resistance of CoCrW coating[J]. Materials Reports, 35, 12123-12129(2021).

[7] Ouyang C S, Liu X B, Luo Y S et al. High-temperature tribological properties of Ti3SiC2-Ni based self-lubricating composite coatings prepared on 304 stainless steel by laser cladding[J]. Surface Technology, 49, 161-171(2020).

[8] Vasantharaja P, Vasudevan M. Optimization of A-TIG welding process parameters for RAFM steel using response surface methodology[J]. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 232, 121-136(2018).

[9] Li C G. Reserch on the geometrical model of cross-section morphology of single laser cladding by powder injection[D](2014).

[10] Gao J L, Wang C, Hao Y B et al. Prediction of TC11 single-track geometry in laser metal deposition based on back propagation neural network and random forest[J]. Journal of Mechanical Science and Technology, 36, 1417-1425(2022).

[11] Wen H J, Meng X L, Xu X C et al. Multi-objective optimization of laser cladding process parameters based on neural network and genetic algorithm[J]. Applied Laser, 39, 734-740(2019).

[12] Yang X Q. Predicting the quality of clad in laser cladding by powder and numerical simulation of cladding process[D](2008).

[13] Wang Y Y, Li J H, Shu L S et al. Multi-objective optimization of laser cladding parameters based on RSM and NSGA-Ⅱ algorithm[J]. Laser & Optoelectronics Progress, 59, 0714004(2022).

[14] Yang S R, Bai H Q, Bao J et al. Prediction of cladding layer morphology based on bp neural network.

[15] Li Q, Li T, Wu Z P et al. Prediction of laser cladding layer area and porosity based on neural network[J]. Applied Laser, 40, 29-34(2020).

[16] Chen S X, Li H Y, Chen H. Prediction of cross section morphology of Ni based cladding layer by laser cladding[J]. Welding & Joining, 9-13, 62(2021).

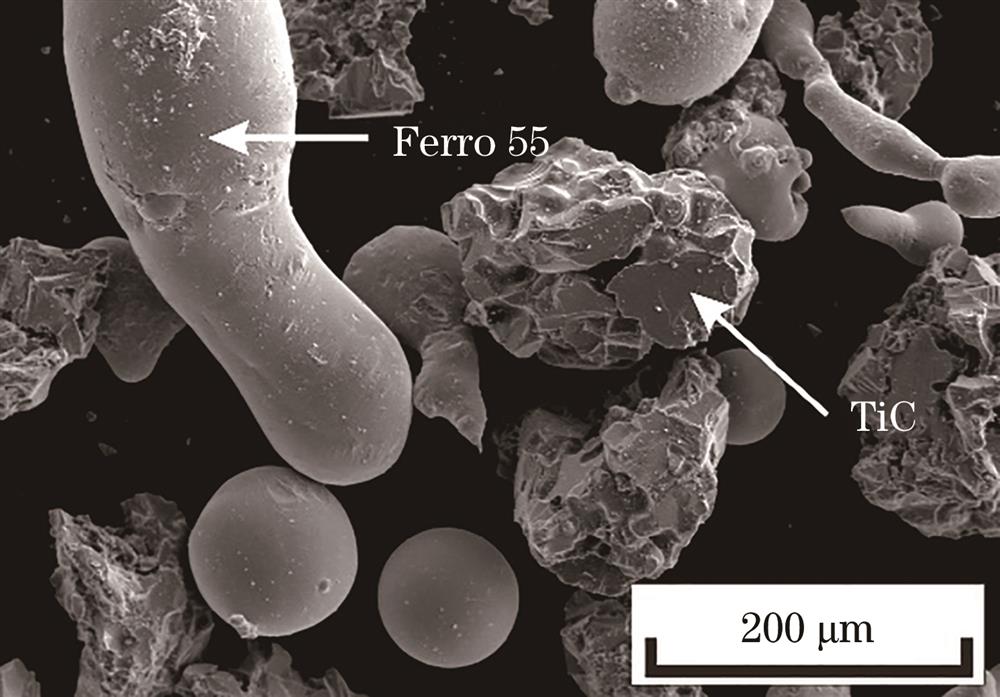

[17] Wang Q T, Zeng X B, Chen C R et al. An integrated method for multi-objective optimization of multi-pass Fe50/TiC laser cladding on AISI 1045 steel based on grey relational analysis and principal component analysis[J]. Coatings, 10, 151(2020).

[18] Fan P F, Zhang G. Prediction on geometrical characteristics of cermet laser cladding based on linear regression and neural network[J]. Surface Technology, 48, 353-359, 368(2019).

[19] Bax B, Rajput R, Kellet R et al. Systematic evaluation of process parameter maps for laser cladding and directed energy deposition[J]. Additive Manufacturing, 21, 487-494(2018).

[20] Lian G F, Xiao S H, Zhang Y et al. Multi-objective optimization of coating properties and cladding efficiency in 316L/WC composite laser cladding based on grey relational analysis[J]. The International Journal of Advanced Manufacturing Technology, 112, 1449-1459(2021).

[21] Ni L B, Liu J C, Wu Y T et al. Optimization of laser cladding process variables based on neural network and particle swarm optimization algorithms[J]. Chinese Journal of Lasers, 38, 0203003(2011).

[22] Alizadeh-Sh M, Marashi S P H, Ranjbarnodeh E et al. Laser cladding of Inconel 718 powder on a non-weldable substrate: clad bead geometry-solidification cracking relationship[J]. Journal of Manufacturing Processes, 56, 54-62(2020).

[23] Liu J C, Ni L B. Prediction of laser clad parameters based on neural network[J]. Materials Technology, 27, 11-14(2012).

[24] Li Y K. Research, analysis and improvement application of BP neural network[D](2012).