Siying LING, Ming LING, Hu LIN, Fengtao WANG, Liding WANG. Research progress in high-precision gear involute artifacts and measuring instruments[J]. Optics and Precision Engineering, 2023, 31(23): 3457

Search by keywords or author

- Optics and Precision Engineering

- Vol. 31, Issue 23, 3457 (2023)

Fig. 1. Gear involute artifact with single base circle from DLUT

![Gear involute artifacts with single base circle from NGML and PTB[18-19]](/richHtml/gxjmgc/2023/31/23/3457/img_2.jpg)

Fig. 3. Involute corrugation artifact from PTB[20]

Fig. 4. Gear involute artifact with rollers from NMIJ[22]

Fig. 5. Gear involute artifact with double design base circles from BelGIM[25]

Fig. 6. Micro-gear involute artifact with multi-modular internal teeth from PTB[27]

Fig. 7. Gear involute artifact with three design base circles from DLUT[30]

Fig. 8. Workpiece gear artifact[31]

Fig. 9. Class-1 master gear from DLUT

Fig. 10. Large involute gear segment measurement standard from PTB[34]

Fig. 11. Large ring gear measurement standard from PTB[36]

Fig. 13. Double-axis arc-shaped large-size involute artifact from BJUT[45]

Fig. 14. Micro gear artifacts[46]

Fig. 15. Involute measurement based on rolling generation

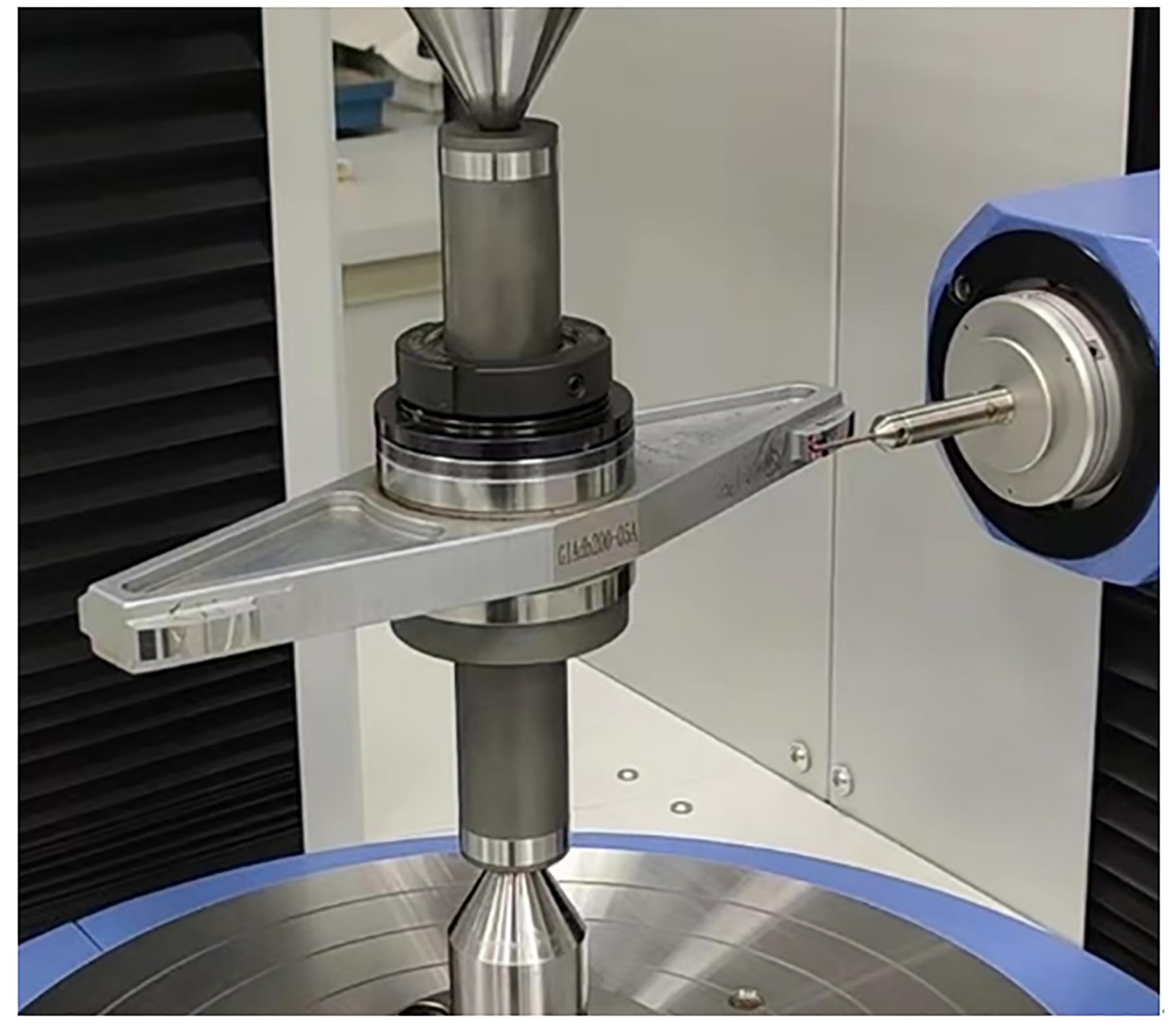

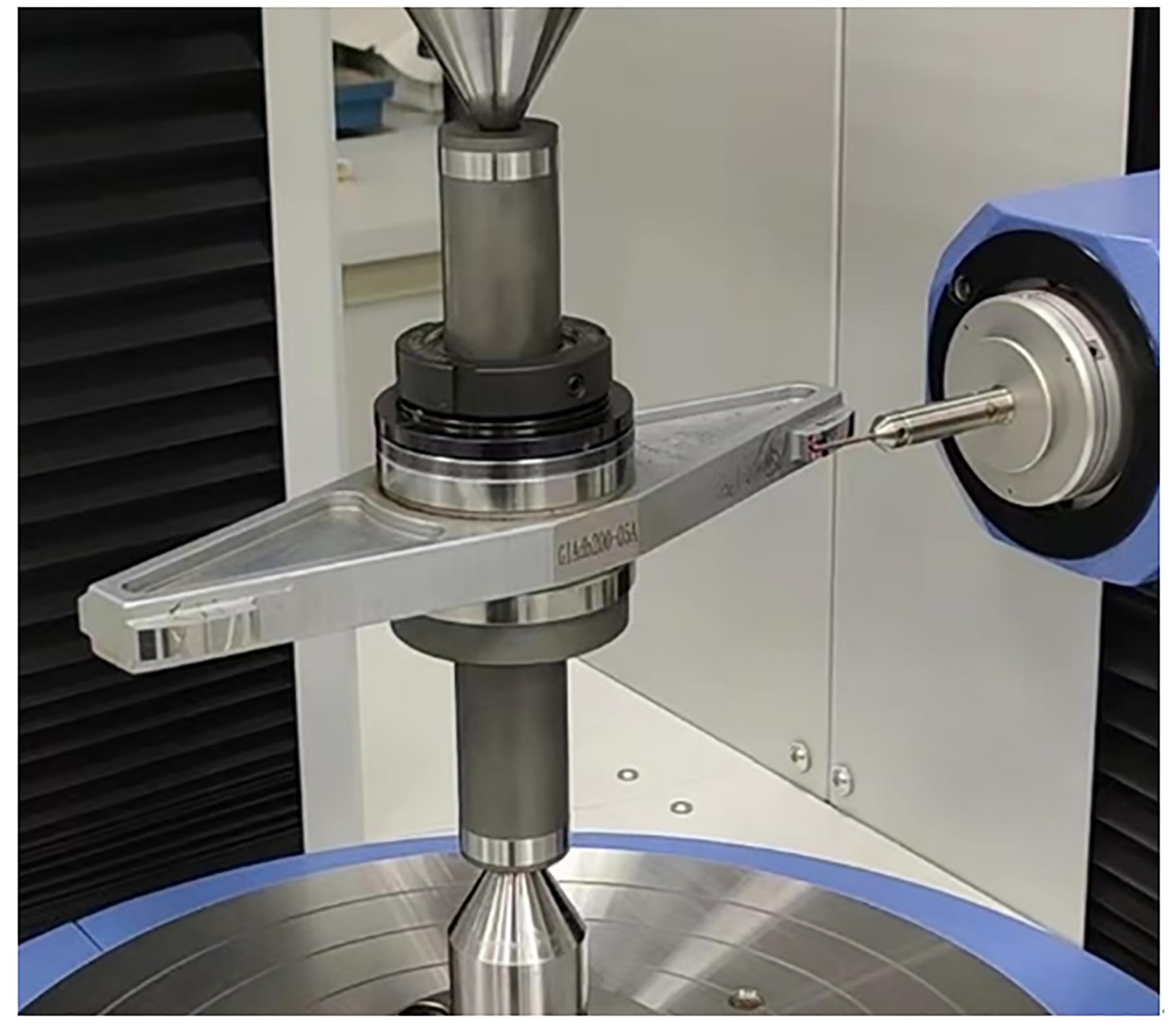

Fig. 16. Gear measuring center(GMC) and its measuring principles[37]

Fig. 17. CMM form PTB(5 m×4 m×2 m)[35]

Fig. 18. Large standard gear with multi-parameters

Fig. 19. Large gear involute artifact assembled with mandrel

Fig. 20. Comparison of evaluation ranges of gear involute artifacts with those of standard gears

Set citation alerts for the article

Please enter your email address