Lei Li, Jing Wang, Lei Huang, Hongyu Zheng, Yuanliang Zhao, Yongling Wu, Langping Wang. Simulation and Analysis of Temperature Field During Oxidation Layer Preparation on Titanium Alloy Using Infrared Laser[J]. Laser & Optoelectronics Progress, 2023, 60(17): 1714006

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 17, 1714006 (2023)

Fig. 1. Finite element model of titanium and mesh generation

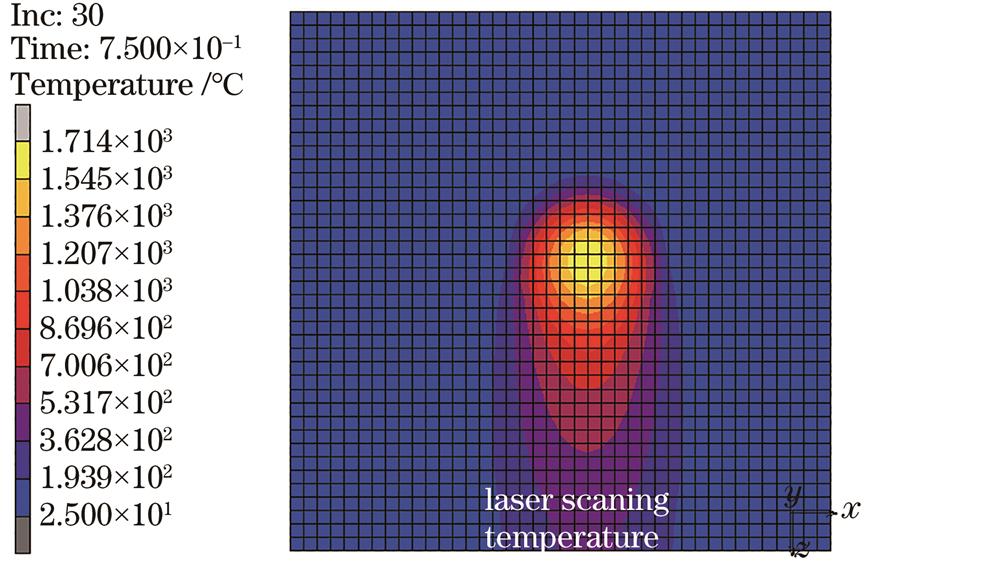

Fig. 2. Temperature distribution on the surface during processing

Fig. 3. Temperatures of surface nodes perpendicular to the scanning path

Fig. 4. Temperature distribution along thickness

Fig. 5. Temperature distribution along vertical direction at the center of laser spot

Fig. 6. Surface morphology of titanium alloy after laser scanning

Fig. 7. Metallographic structure of titanium alloy in section direction after laser scanning

Fig. 8. Metallographic structure of partially transformed zone

Fig. 9. Surface temperature varies with time under different scanning rates

Fig. 10. Surface temperature and temperature distribution along thickness under different scanning rates. (a) Surface temperature distribution; (b) temperature distribution along thickness

Fig. 11. Surface morphology of titanium alloy and microstructure and composition of oxide layer under No.2 parameter. (a) Surface morphology of titanium alloy after laser scanning; (b) oxide layer on the surface; (c) energy spectrum results of the oxide layer

Fig. 12. Variation of surface node temperature with time at the spot under different parameters

Fig. 13. Temperature distribution along the thickness direction under different parameters

Fig. 14. Variation of surface node temperature at different scanning time intervals

|

Table 1. Thermophysical properties of Ti6Al4V alloy[19]

|

Table 2. Chemical composition of Ti6Al4V alloy

|

Table 3. Laser processing parameters simulated by finite element

Set citation alerts for the article

Please enter your email address