Chenxin Wang, Yonggang Zou, Jie Fan, Linlin Shi, Yuxin Yue, Yingmin Song, Hongjin Liang. Thermal Characteristics Analysis of Multi-Material Composite Heat Sink Structure Based on VCSEL Array[J]. Laser & Optoelectronics Progress, 2025, 62(3): 0316002

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 62, Issue 3, 0316002 (2025)

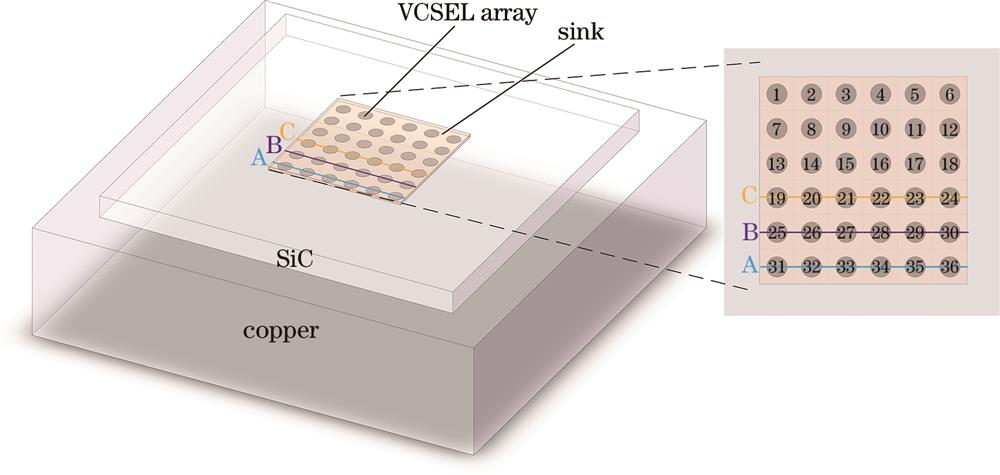

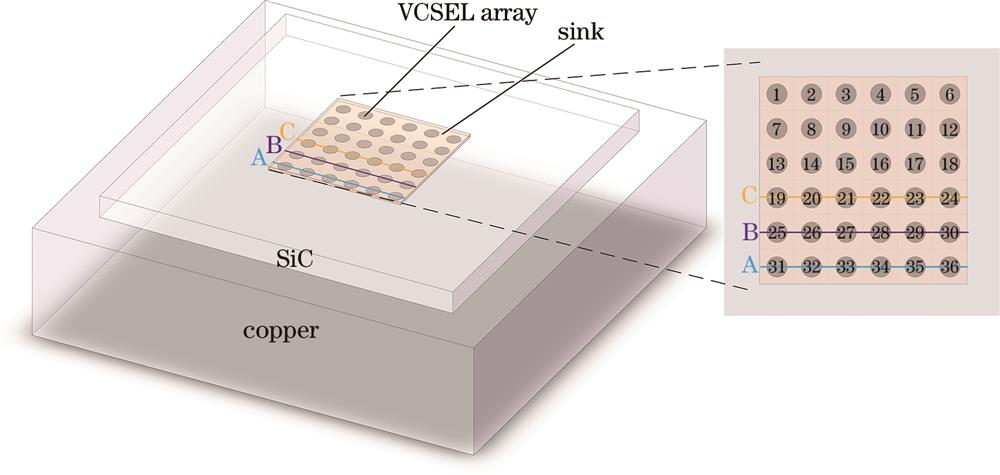

Fig. 1. Traditional structure schematic diagram

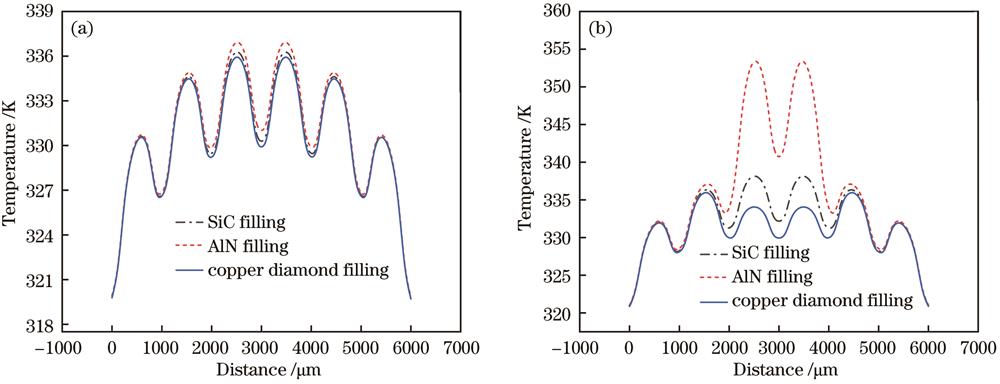

Fig. 2. Temperature distribution curve diagrams of VCSEL array along different paths with different groove filling materials. (a) Path B; (b) path C

Fig. 3. Temperature distribution curve diagrams of VCSEL array along different paths under different groove depths.(a) Path B; (b) path C

Fig. 4. Temperature distribution curve diagrams along paths A, B, and C for devices with grooves filled with copper-diamond material underneath units 15, 16, 21, and 22

Fig. 5. Simplified schematic diagram of novel multi-material composite heat sink

Fig. 6. Device temperature distribution diagrams under two different heat dissipation structures. (a) Traditional structure; (b) optimized structure

Fig. 7. Temperature distribution curves along paths A, B, and C for devices encapsulated with traditional heat dissipation structure and new heat dissipation structure

Fig. 8. P-I characteristic curves under different thermal resistances

|

Set citation alerts for the article

Please enter your email address