Zhihui Huang, Qike Ye, Qijiao Ye, Jianhong Liao. Study on Process and Quality of Dual Laser Etching and Cleaning Flexible Copper Clad Laminate[J]. Laser & Optoelectronics Progress, 2023, 60(17): 1714005

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 17, 1714005 (2023)

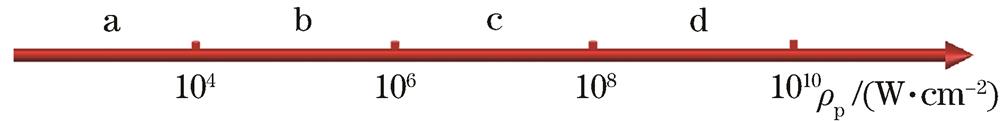

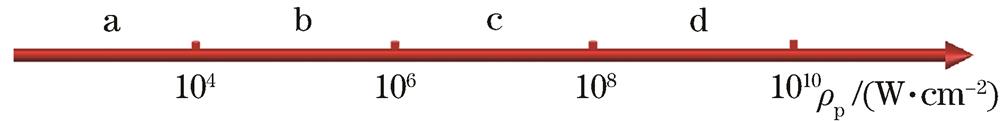

Fig. 1. Four stages of laser-material interaction at different power densities

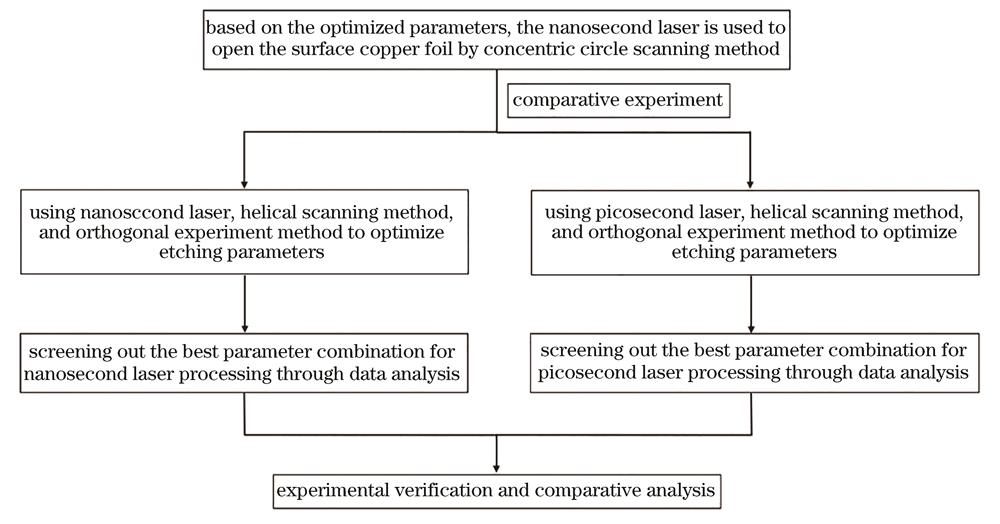

Fig. 2. Experimental scheme

Fig. 3. FCCL first-order blind hole machining schematic. (a) Schematic diagram of copper foil etching by nanosecond laser concentric scanning method; (b) copper foil layer etching profile; (c) schematic diagram of spiral scanning method of etching and cleaning blind hole; (d) schematic diagram of the first-order blind hole section

Fig. 4. Laser etched copper layer morphology. (a) Radius measurement chart under optical microscope; (b) three-dimensional height map under laser confocal microscope

Fig. 5. Observation diagram of laser etching and cleaning blind hole. (a) Nanosecond laser etching and cleaning morphology under optical microscope; (b) picosecond laser etching and cleaning morphology under optical microscope;(c) nanosecond laser processing blind hole two-dimensional profile; (d) picosecond laser processing blind hole two-dimensional contour diagram

Fig. 6. Optimized parameters for picosecond laser etching and cleaning of blind hole. (a) Three-dimensional color map under laser confocal microscope; (b) profile color map; (c) three-dimensional height map; (d) profile height map

|

Table 1. Laser processing experimental equipment parameters

|

Table 2. Factor level table

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 3. Orthogonal experimental factor design and results

|

Table 4. Range analysis

|

Table 5. Factor level table

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table 6. Orthogonal experimental factor design and results

|

Table 7. Range analysis

|

Table 8. Optimization process etching results

Set citation alerts for the article

Please enter your email address