Songze WU, Yang ZHOU, Runfeng LI, Xiaoqian LIU, Cuiwei LI, Zhenying HUANG. Reaction Sintered Porous Ceramics Using Iron Tailings: Preparation and Properties [J]. Journal of Inorganic Materials, 2023, 38(10): 1193

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 38, Issue 10, 1193 (2023)

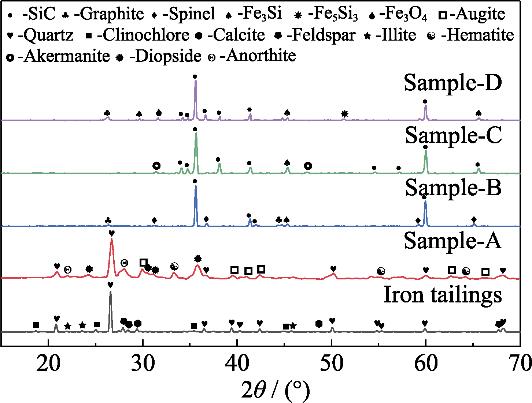

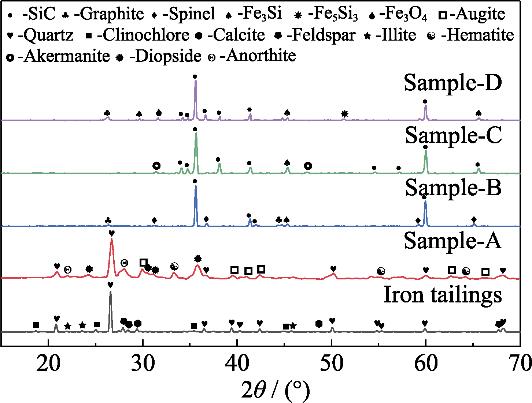

1. XRD patterns of iron tailings raw materials and test samples

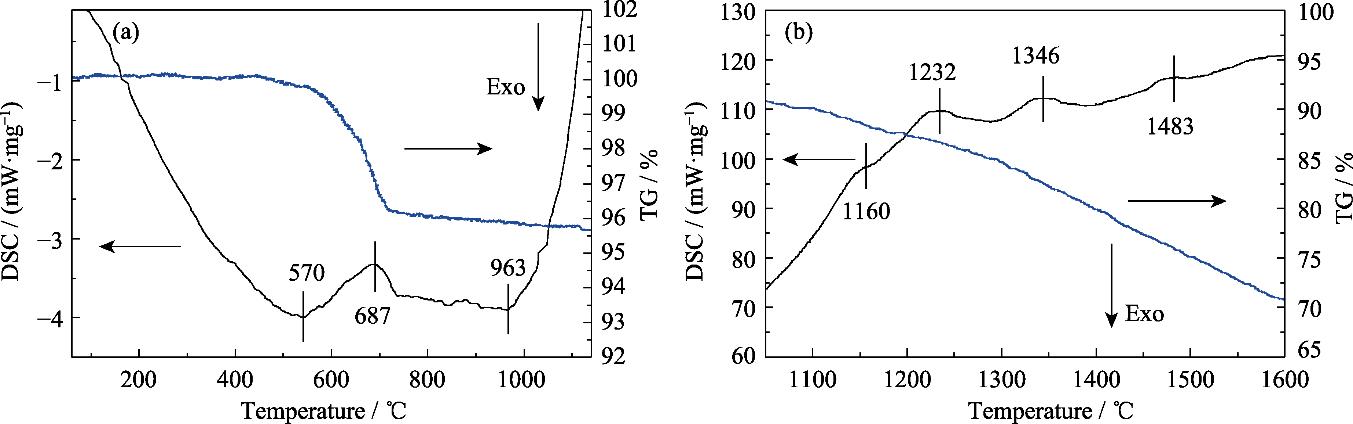

2. DSC-TG curves for (a) iron tailings and (b) iron tailing-graphite

3. Macrostructures of porous ceramics

4. (a, c, e, g) Fracture morphologies and (b, d, f, h) skeleton microstructures of porous ceramic Sample A, Sample B, Sample C, and Sample D

5. Bulk density and apparent porosity of porous ceramics

6. Compressive strengths and thermal conductivities of porous ceramics

|

Table 1. Composition of iron tailings raw materials

|

Table 2. Composition, forming and sintering technology of porous ceramics prepared using iron tailings by different methods

Set citation alerts for the article

Please enter your email address