[2] A BEYLOT, F BODéNAN, A G GUEZENNEC et al. LCA as a support to more sustainable tailings management: critical review, lessons learnt and potential way forward. Resources, 106347(2022).

[3] V S PIFFER, K SOARES, A G S GALDINO. Evaluation of mechanical and thermal properties of PP/iron ore tailing composites. Composites Part B: Engineering, 221: 109001(2021).

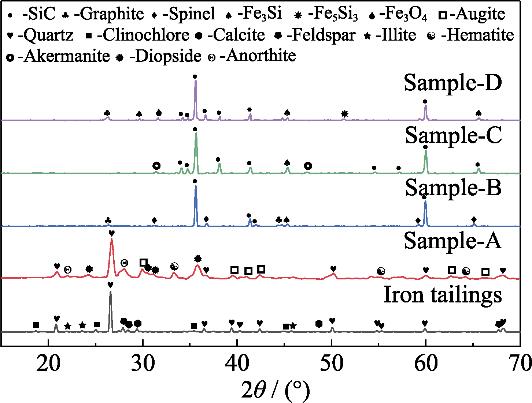

[5] C YANG, C CUI, J QIN. Recycling of low-silicon iron tailings in the production of lightweight aggregates. Ceramics International(2015).

[6] J ZHAO, K NI, Y SU et al. An evaluation of iron ore tailings characteristics and iron ore tailings concrete properties. Construction and Building Materials, 286: 122968(2021).

[7] P N LEMOUGNA, J YLINIEMI, H NGUYEN et al. Utilisation of glass wool waste and mine tailings in high performance building ceramics. Journal of Building Engineering, 31: 101383(2020).

[8] Y CHENG, F HUANG, W LI et al. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Construction and Building Materials, 118: 164(2016).

[9] Y LUO, F WANG, Q LIAO et al. Effect of TiO2 on crystallization kinetics, microstructure and properties of building glass-ceramics based on granite tailings. Journal of Non-Crystalline Solids, 572: 121092(2021).

[10] Y PENG, Z LIU, X LIU et al. Preparation of composite micro-slag based on the application of tailings slag in cement and concrete. Construction and Building Materials, 322: 126515(2022).

[11] J S ADIANSYAH, M ROSANO, S VINK et al. A framework for a sustainable approach to mine tailings management: disposal strategies. Journal of Cleaner Production, 108: 1050(2015).

[13] ANH L D HUNG, Z PÁSZTORY. An overview of factors influencing thermal conductivity of building insulation materials. Journal of Building Engineering, 44: 102604(2021).

[14] L ADITYA, T M I MAHLIA, B RISMANCHI et al. A review on insulation materials for energy conservation in buildings. Renewable and Sustainable Energy Reviews, 73: 1352(2017).

[15] D N NKWETTA, F HAGHIGHAT. Thermal energy storage with phase change material—a state-of-the art review. Sustainable Cities and Society, 10: 87(2014).

[16] W VILLASMIL, L J FISCHER, J WORLITSCHEK. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renewable and Sustainable Energy Reviews, 103: 71(2019).

[17] S WI, J H PARK, Y U KIM et al. Thermal, hygric, and environmental performance evaluation of thermal insulation materials for their sustainable utilization in buildings. Environmental Pollution, 272: 116033(2021).

[18] H GAO, H LIU, L LIAO et al. A novel inorganic thermal insulation material utilizing perlite tailings. Energy and Buildings, 190: 25(2019).

[19] J ZHAO, S LI. Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials—a review. Energy and Buildings, 254: 111582(2022).

[20] B ABU-JDAYIL, A H MOURAD, W HITTINI et al. Traditional, state-of-the-art and renewable thermal building insulation materials: an overview. Construction and Building Materials, 214: 709(2019).

[21] P ARUMUGAM, V RAMALINGAM, P VELLAICHAMY. Effective PCM, insulation, natural and/or night ventilation techniques to enhance the thermal performance of buildings located in various climates—a review. Energy and Buildings, 258: 111840(2022).

[22] D C GAO, Y SUN, A M L FONG et al. Mineral-based form-stable phase change materials for thermal energy storage: a state-of-the art review. Energy Storage Materials, 46: 100(2022).

[25] C VAKIFAHMETOGLU, D ZEYDANLI, P COLOMBO. Porous polymer derived ceramics. Materials Science and Engineering: R: Reports, 106: 1(2016).

[26] Q SONG, J BAO, S XUE et al. Study on the recycling of ceramic polishing slag in autoclaved aerated foam concrete by response surface methodology. Journal of Building Engineering, 56: 104827(2022).

[28] Y WANG, X HUANG, J CHU et al. Analysis of polishing waste ceramic foam packing in evaporative cooling. Applied Thermal Engineering, 212: 118477(2022).

[30] C TIAN, X HUANG, W GUO et al. Preparation of SiC porous ceramics by a novel gelcasting method assisted with surface modification. Ceramics International(2020).

[32] E C HAMMEL, O L R IGHODARO, O I OKOLI. Processing and properties of advanced porous ceramics: an application based review. Ceramics International(2014).

[34] K S P KARUNADASA, C H MANORATNE, PITAWALA H et al. Thermal decomposition of calcium carbonate (calcite polymorph) as examined by

[36] H CHEN, B LI, M ZHAO et al. Lanthanum modification of crystalline phases and residual glass in augite glass ceramics produced with industrial solid wastes. Journal of Non-Crystalline Solids, 524: 119638(2019).