Wenxin QUAN, Yiping YU, Bing FANG, Wei LI, Song WANG. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920

Search by keywords or author

- Journal of Inorganic Materials

- Vol. 39, Issue 8, 920 (2024)

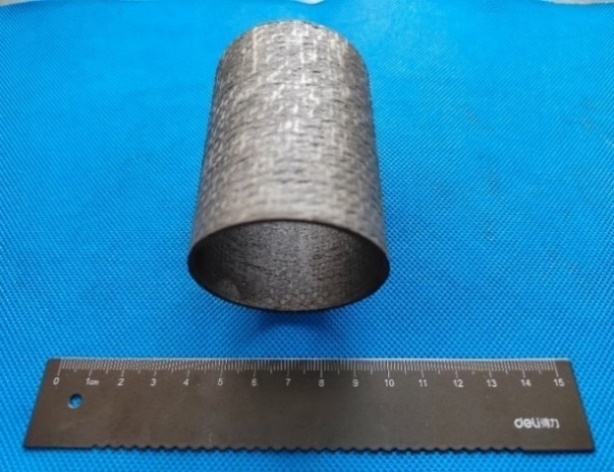

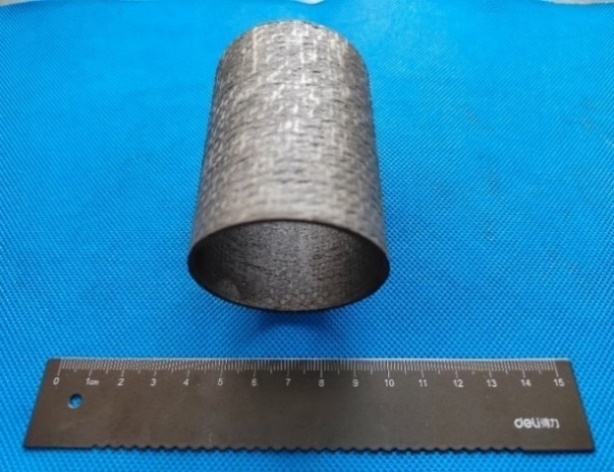

1. Tubular specimen of C/SiC composite

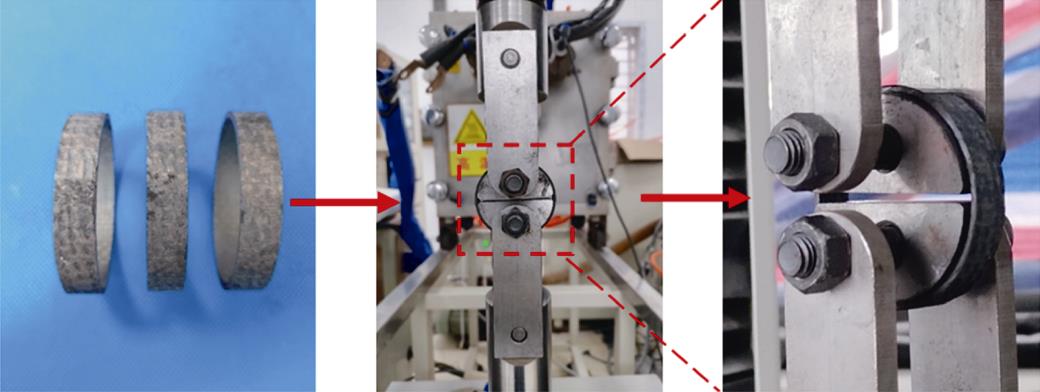

2. Ring tensile experiment of C/SiC composite

3. Crack healed through thermal expansion and oxidation of SiC matrix

4. Diffusion of oxygen in SiC cracks (a) and oxidation channel of carbon fibers (b)

5. Equivalent oxidation depth of tubular C/SiC composite

6. Mass retention rate (a), function fitting of $ \left(1-\eta_{\mathrm{m}}\right)^{2}$ with t (b), strength retention rate (c), and function fitting of $ \left(1-\eta_{\mathrm{R}}\right)^{2}$ with t (d) for tubular C/SiC composites after high-temperature air oxidation

7. Morphology and distributions of elements on the surface of tubular C/SiC composite

8. Microstructures at fractures of tubular C/SiC composites after high-temperature air oxidation

9. Microstructures at fractures of carbon fibers in tubular C/SiC composites after high-temperature air oxidation

10. Microstructures of cross-sections of tubular C/SiC composites after high-temperature air oxidation

11. EDS distributions of oxygen contents at cross sections of tubular C/SiC composites after 1100 ℃-1 h (a), 1300 ℃-0.5 h (b) and 1300 ℃-1 h (c) high-temperature air oxidation

12. Distributions of mole fraction of oxygen (a), gradient of mole fraction (b) and mole fraction with diffusion progress (c) in microcracks of SiC matrix

13. Predicted results of strength retention rate (a) and mass retention rate (b)

|

Table 1. Parabolic rate constant of SiC in air oxidation

|

Table 2. Parameters of oxidation for 10 h

|

Table 3. Modifying factor of equivalent oxidation depth

Set citation alerts for the article

Please enter your email address