Xiaming Chen, Luzhong Zhang, Kunlun Qin, Jia Song, Xiaonan Wang, Nagaumi Hiromi. Study on Porosity Suppression for Laser Welds of High-Pressure Die-Casting Al-Si Alloys[J]. Chinese Journal of Lasers, 2025, 52(8): 0802109

Search by keywords or author

- Chinese Journal of Lasers

- Vol. 52, Issue 8, 0802109 (2025)

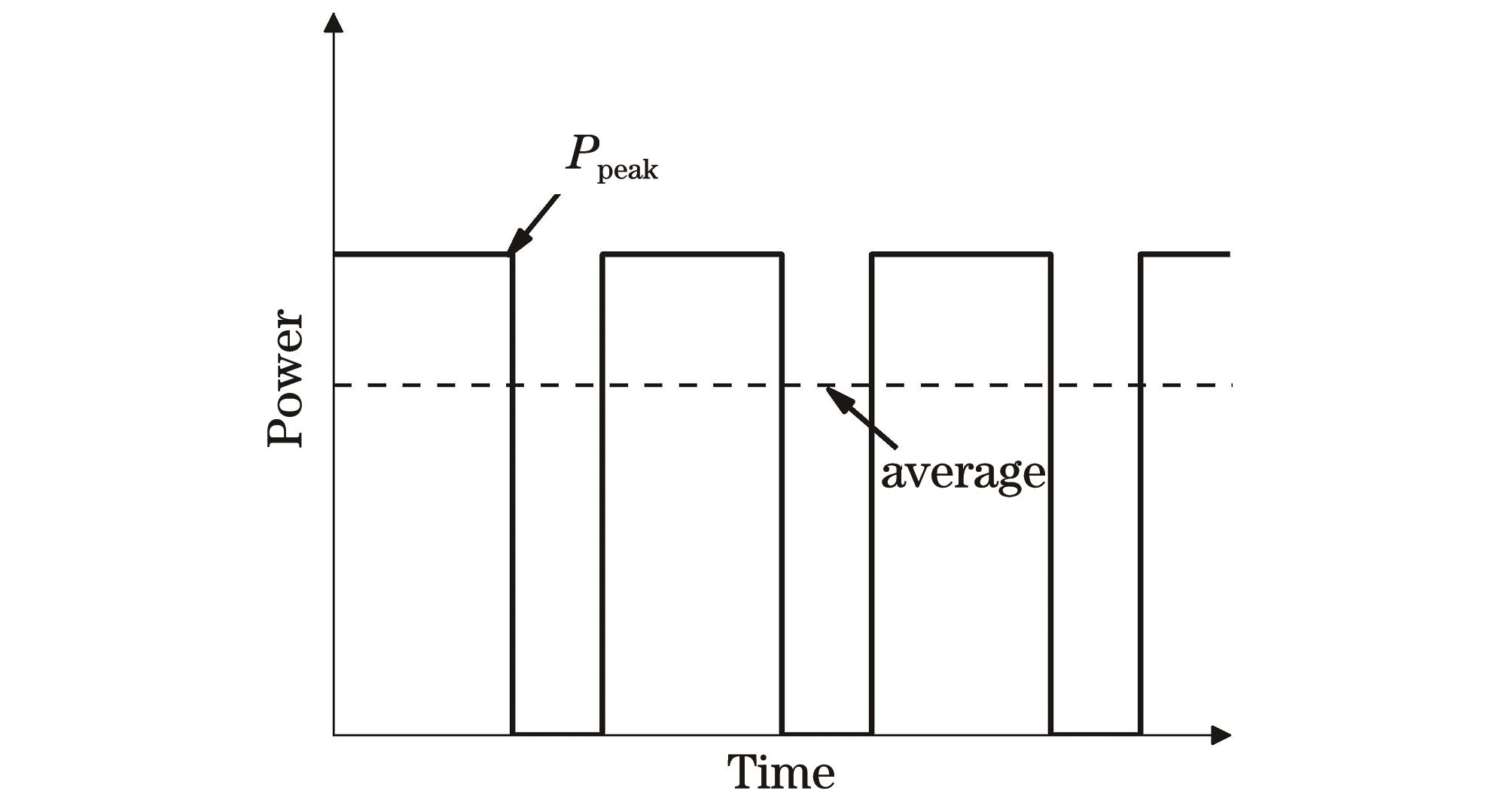

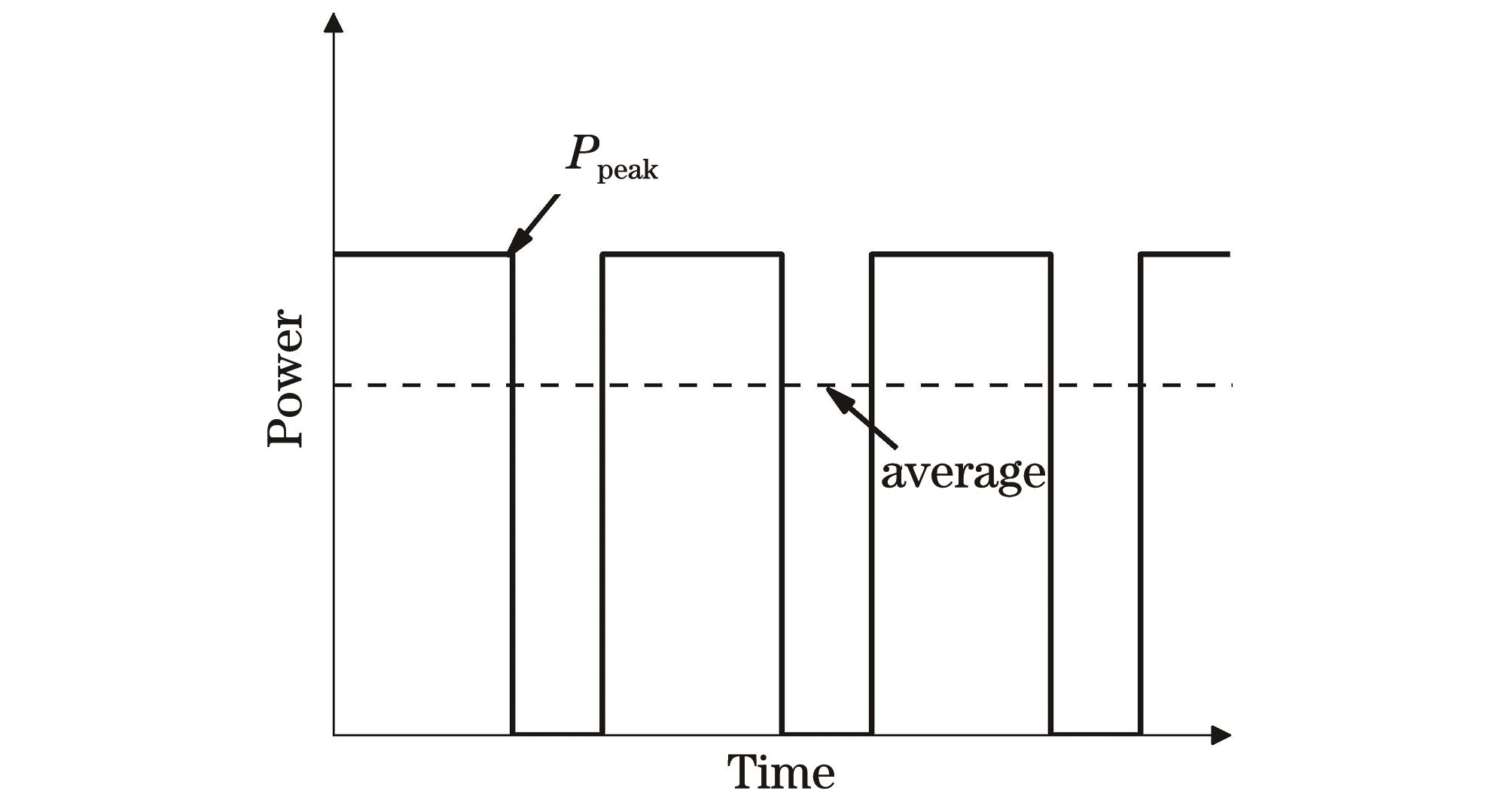

Fig. 1. Schematic diagram of QCW waveform

Fig. 2. Cross section and longitudinal section morphologies of weld seams. (a) CW; (b) QCW

Fig. 3. Diameter distribution and porosity of keyhole type pores in longitudinal section of weld seam under different welding processes.

Fig. 4. Distributions of pores in cross section and longitudinal section of weld seams under different QCW frequencies. (a) 5 Hz; (b) 10 Hz; (c) 20 Hz

Fig. 5. Diameter distribution and porosity of keyhole type pores in longitudinal section of weld seam under different QCW laser frequencies. (a) Box plot of diameter distribution of keyhole type pores; (b) porosity

Fig. 6. Keyhole and molten pool dynamic behavior during two welding processes. (a) CW; (b) QCW

Fig. 7. Tensile test results of welded joints. (a) Engineering stress-strain curves; (d) macro-morphologies of fractures

|

Table 1. Chemical compositions of high-pressure die-casting Al-Si alloy (mass fraction, %)

|

Table 2. Laser welding parameters

Set citation alerts for the article

Please enter your email address