[1] Li Y Y, Si Y H, Xiong X B et al. Research and progress on three dimensional printing of ceramic materials[J]. Journal of the Chinese Ceramic Society, 45, 793-805(2017).

[2] Chen Z W, Li Z Y, Li J J et al. 3D printing of ceramics: a review[J]. Journal of the European Ceramic Society, 39, 661-687(2019).

[3] Bertrand P, Bayle F, Combe C et al. Ceramic components manufacturing by selective laser sintering[J]. Applied Surface Science, 254, 989-992(2007).

[5] Shahzad K, Deckers J, Zhang Z Y et al. Additive manufacturing of zirconia parts by indirect selective laser sintering[J]. Journal of the European Ceramic Society, 34, 81-89(2014).

[6] Zhao Y Y, Luo H C, Liang Z X et al. Micro-nano 3D printing based on photopolymerization and its development status and trends[J]. Chinese Journal of Lasers, 49, 1002703(2022).

[7] Huang B W. Study on the properties of SL5530 type photosensitive resin for stereolithography in 3D printing[C], 101-102(2015).

[8] Wang Z Y, Cai Z X, Liu G C et al. Laser 3D printing and properties of HAP-TCP composite bioceramic materials[J]. Materials Reports, 35, 104-107, 131(2021).

[9] Liu F H. Manufacturing porous multi-channel ceramics by laser gelling[J]. Ceramics International, 37, 2789-2794(2011).

[10] Mühler T, Gomes C M, Heinrich J et al. Slurry-based additive manufacturing of ceramics[J]. International Journal of Applied Ceramic Technology, 12, 18-25(2015).

[11] Yen H C, Tang H H. Study on direct fabrication of ceramic shell mold with slurry-based ceramic laser fusion and ceramic laser sintering[J]. The International Journal of Advanced Manufacturing Technology, 60, 1009-1015(2012).

[12] Tang H H, Liu F H, Lin W H. Rapid prototyping machine based on ceramic laser fusion[J]. The International Journal of Advanced Manufacturing Technology, 30, 687-692(2006).

[13] Tang H H, Yen H C. Slurry-based additive manufacturing of ceramic parts by selective laser burn-out[J]. Journal of the European Ceramic Society, 35, 981-987(2015).

[14] Ahn D, Kweon J H, Choi J et al. Quantification of surface roughness of parts processed by laminated object manufacturing[J]. Journal of Materials Processing Technology, 212, 339-346(2012).

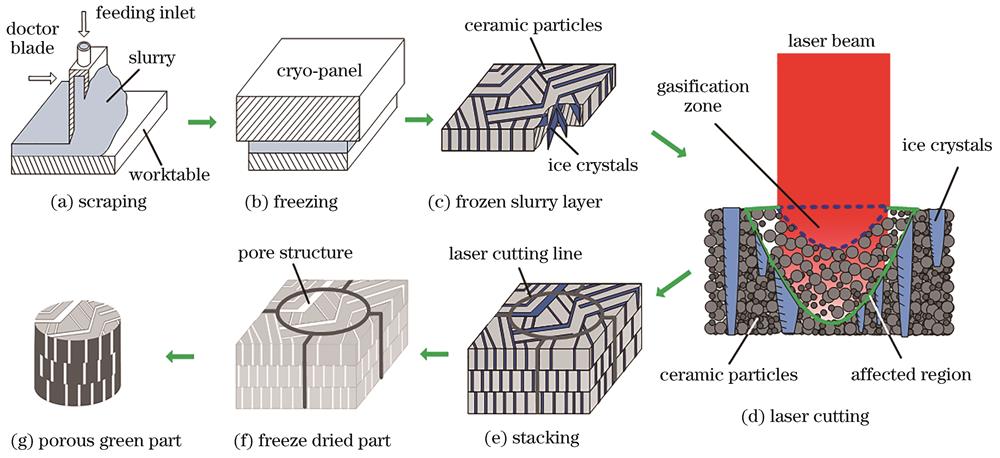

[15] Zhang G, Chen H, Yang S B et al. Frozen slurry-based laminated object manufacturing to fabricate porous ceramic with oriented lamellar structure[J]. Journal of the European Ceramic Society, 38, 4014-4019(2018).

[16] Li J H, An X J, Yao F P et al. Simulation on thermal stress cycle in laser cladding of H13 steel Ni-based coating[J]. Chinese Journal of Lasers, 48, 1002104(2021).