Qi Yang, Pengfei Guo, Zhen Wang, Changshuai Zhai, Jianfeng Geng, Huijun Wang, Jun Yu, Xin Lin. Influence of Pulse Laser on Microstructure and Property of TiB2 /Inconel 718 Composite Fabricated by Laser Powder Bed Fusion[J]. Chinese Journal of Lasers, 2025, 52(8): 0802303

Search by keywords or author

- Chinese Journal of Lasers

- Vol. 52, Issue 8, 0802303 (2025)

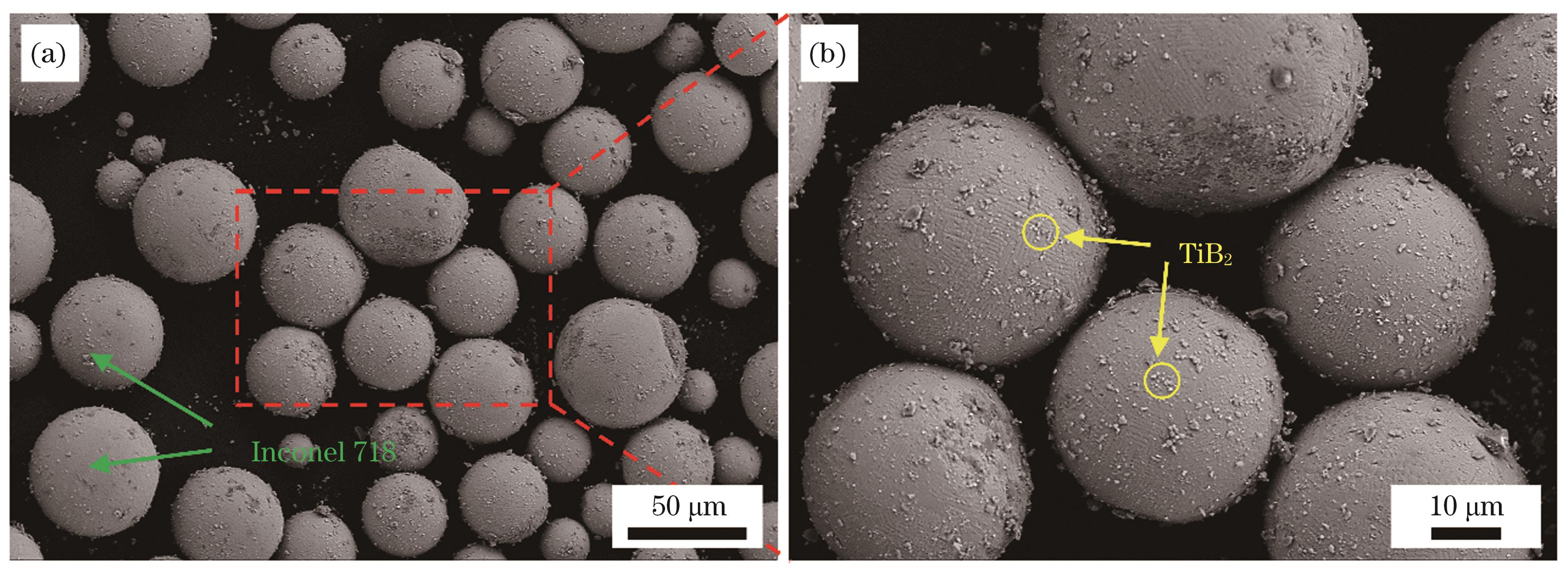

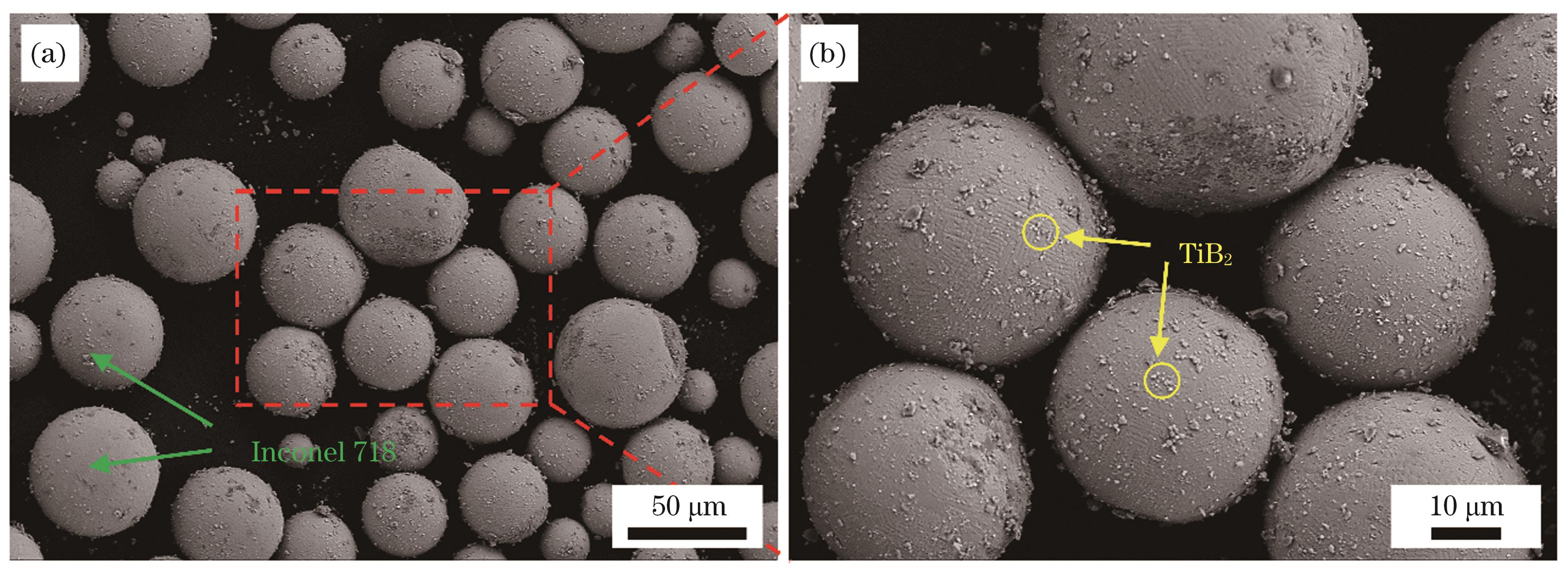

Fig. 1. SEM images of mixed powder. (a) Low magnification image; (b) high magnification image

Fig. 2. Schematic diagrams of P-LPBF. (a) Schematic diagram of P-LPBF process; (b) waveform of pulsed laser

Fig. 3. Density of P-LPBF formed TiB2/Inconel 718 composite versus laser volumetric energy density

Fig. 4. Defect distributions in vertical section and horizontal section of P-LPBF formed TiB2/Inconel 718 composite under OM. (a)(e) ε=190.5 J/mm3; (b)(f) ε=165.1 J/mm3; (c)(g) ε=139.7 J/mm3; (d)(h) ε=114.3 J/mm3

Fig. 5. P-LPBF formed TiB2/Inconel 718 composite under laser volumetric energy density of 222.9 J/mm³. (a) Macroscopic grain morphology in vertical section; (b) macroscopic grain morphology in horizontal section; (c) microstructure in vertical section; (d) microstructure in horizontal section

Fig. 6. Element segregation of P-LPBF formed TiB₂/Inconel 718 composite under laser volumetric energy density of 222.9 J/mm3.

Fig. 7. Comparison of macroscopic grain morphologies in vertical section of P-LPBF formed TiB2/Inconel 718 composite under different laser volumetric energy density values. (a) 266.7 J/mm3; (b) 241.3 J/mm3; (c) 222.9 J/mm3; (d) 201.6 J/mm3

Fig. 8. Comparison of microscopic dendritic morphologies in vertical section of P-LPBF formed TiB2/Inconel 718 composite under different laser volumetric energy density values. (a) 266.7 J/mm3; (b) 241.3 J/mm3; (c) 222.9 J/mm3; (d) 201.6 J/mm3

Fig. 9. Comparison of TiB2 particle distributions in P-LPBF formed TiB2/Inconel 718 composite under different laser volumetric energy density values. (a) 266.7 J/mm3; (b) 241.3 J/mm3; (c) 222.9 J/mm3; (d) 201.6 J/mm3

Fig. 10. Vickers hardness test results. (a) Hardness distributions; (b) hardness versus laser volumetric energy density

Fig. 11. Primary dendritic spacing distributions of each sample under different laser volumetric energy density values. (a) 266.7 J/mm3; (b) 241.3 J/mm3; (c) 222.9 J/mm3; (d) 201.6 J/mm3

Fig. 12. Relationship between λ1 of P-LPBF formed TiB2/Inconel 718 composite and El

Fig. 13. Distributions of flow fields inside molten pool[19]. (a) Continuous laser; (b) pulsed laser

|

Table 1. Experimental parameters of LPBF

Set citation alerts for the article

Please enter your email address