[1] J WEI, L YANG, Z MA et al. Review of current high-ZT thermoelectric materials. Journal of Materials Science(2020).

[2] H T LIU, Q SUN, Y ZHONG et al. Enhanced thermoelectric performance of n-type Nb-doped PbTe by compensating resonant level and inducing atomic disorder. Materials Today Physics(2022).

[3] L SU, D WANG, S WANG et al. High thermoelectric performance realized through manipulating layered phonon-electron decoupling. Science(2022).

[4] J SUN, R WANG, W CUI et al. Percolation process-mediated rich defects in hole-doped PbSe with enhanced thermoelectric performance. Chemistry of Materials(2022).

[5] D AN, J WANG, J ZHANG et al. Retarding Ostwald ripening through Gibbs adsorption and interfacial complexions leads to high-performance SnTe thermoelectrics. Energy & Environmental Science(2021).

[6] J YANG, G LI, H ZHU et al. Next-generation thermoelectric cooling modules based on high-performance Mg3(Bi,Sb)2 material. Joule(2022).

[7] J CHU, J HUANG, R LIU et al. Electrode interface optimization advances conversion efficiency and stability of thermoelectric devices. Nature Communications(2020).

[8] R BJØRK. The universal influence of contact resistance on the efficiency of a thermoelectric generator. Journal of Electronic Materials(2015).

[9] Q H ZHANG, S Q BAI, L D CHEN. Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials(2019).

[10] X WU, Z HAN, Y ZHU et al. A general design strategy for thermoelectric interface materials in n-type Mg3Sb1.5Bi0.5 single leg used in TEGs. Acta Materialia(2022).

[11] X K HU, S M ZHANG, F ZHAO et al. Thermoelectric device: contact interface and interface materials. Journal of Inorganic Materials(2019).

[12] M SAKANO, M HIRAYAMA, T TAKAHASHI et al. Radial spin texture in elemental tellurium with chiral crystal structure. Physical Review Letters(2020).

[13] J R REITZ. Electronic band structure of selenium and tellurium. Physical Review(1957).

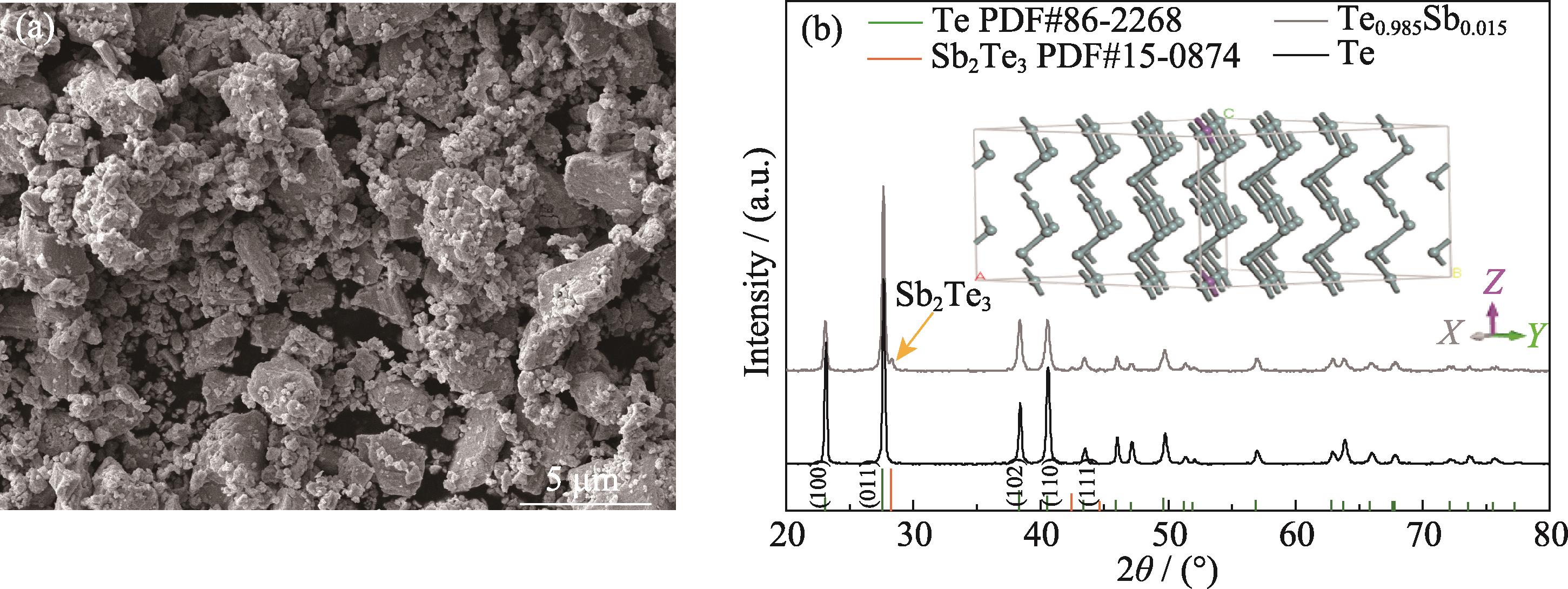

[15] S Q LIN, W LI, X Y ZHANG et al. Sb induces both doping and precipitation for improving the thermoelectric performance of elemental Te.. Inorganic Chemistry Frontiers(2017).

[16] F RAO, K DING, Y ZHOU et al. Reducing the stochasticity of crystal nucleation to enable subnanosecond memory writing. Science(2017).

[17] J GUO, W FAN, Y WANG et al. Study on improving comprehensive property of Te-based thermoelectric joint. Journal of Alloys and Compounds(2021).

[19] Z HE, L G CHANG, Y LIN et al. Real-time visualization of solid-phase ion migration kinetics on nanowire monolayer. Journal of the American Chemical Society(2020).

[20] M TASHIRO, S SUKENAGA, K IKEMOTO et al. Interfacial reactions between pure Cu, Ni, and Ni-Cu alloys and p-type Bi2Te3 bulk thermoelectric material. Journal of Materials Science(2021).

[21] X R FERRERES, YAMINI S AMINORROAYA, M NANCARROW et al. One-step bonding of Ni electrode to n-type PbTe—a step towards fabrication of thermoelectric generators. Materials & Design(2016).

[22] J ZHANG, P WEI, H ZHANG et al. Enhanced contact performance and thermal tolerance of Ni/Bi2Te3 joints for Bi2Te3-based thermoelectric devices. ACS Applied Materials & Interfaces(2023).

[23] J CHEN, W FAN, Y WANG et al. Improvement of stability in a Mg2Si-based thermoelectric single-leg device

[24] Y WANG, J CHEN, Y JIANG et al. Suppression of interfacial diffusion in Mg3Sb2 thermoelectric materials through an Mg4.3Sb3Ni/Mg3.2Sb2Y0.05/Mg4.3Sb3Ni-graded structure. ACS Applied Materials & Interfaces(2022).

[25] S CHEN, J CHEN, W FAN et al. Improvement of contact and bonding performance of Mg2Si/Mg2SiNi3 thermoelectric joints by optimizing the concentration gradient of Mg.. Journal of Electronic Materials(2022).

[26] Y SUN, L YIN, Z ZHANG et al. Low contact resistivity and excellent thermal stability of p-type YbMg0.8Zn1.2Sb2/Fe-Sb junction for thermoelectric applications. Acta Materialia(2022).

[27] Z SUN, X CHEN, J ZHANG et al. Achieving reliable CoSb3 based thermoelectric joints with low contact resistivity using a high-entropy alloy diffusion barrier layer. Journal of Materiomics(2022).

[28] C M ARVHULT, C GUÉNEAU, S GOSSÉ et al. Thermodynamic assessment of the Ni-Te system. Journal of Materials Science(2019).

[29] C N LIAO, C H LEE, W J CHEN. Effect of interfacial compound formation on contact resistivity of soldered junctions between bismuth telluride-based thermoelements and copper. Electrochemical and Solid-State Letters(2007).

[30] H XIA, C L CHEN, F DRYMIOTIS et al. Interfacial reaction between Nb foil and n-type PbTe thermoelectric materials during thermoelectric contact fabrication. Journal of Electronic Materials(2014).

[31] C C LI, F DRYMIOTIS, L L LIAO et al. Interfacial reactions between PbTe-based thermoelectric materials and Cu and Ag bonding materials. Journal of Materials Chemistry C(2015).

[32] X WANG, M GU, J C LIAO et al. High temperature interfacial stability of Fe/Bi0.5Sb1.5Te3 thermoelectric elements. Journal of Inorganic Materials(2021).

[33] K TSUTOMU, T HIROMASA, H K SATO et al. Enhancement of average thermoelectric figure of merit by increasing the grain-size of Mg3.2Sb1.5Bi0.49Te0.01. Applied Physics Letters(2018).

[34] D AN, S CHEN, Z LU et al. Low thermal conductivity and optimized thermoelectric properties of p-type Te-Sb2Se3: synergistic effect of doping and defect engineering. ACS Applied Materials & Interfaces(2019).

[35] L NORÉN, V TING, R L WITHERS et al. An electron and X-ray diffraction investigation of Ni1+

[36] J S ANDERSON. Nonstoichiometric compounds: a critique of current structural views. Proceedings of the Indian Academy of Sciences - Chemical Sciences(1984).

[37] J CHEN, Y ZHANG, Z YU et al. Interface growth and void formation in Sn/Cu and Sn0.7Cu/Cu systems. Applied Sciences(2018).

[38] Y LIN, X WU, Y LI et al. Revealing multi-stage growth mechanism of Kirkendall voids at electrode interfaces of Bi2Te3-based thermoelectric devices with

[39] R LIU, Y XING, J LIAO et al. Thermal-inert and ohmic-contact interface for high performance half-Heusler based thermoelectric generator. Nature Communications(2022).

[40] R G J BALL, S DICKINSON, E H P CORDFUNKE et al. Thermochemical data acquisition. Part II. Luxembourg: Commission of the European Communities.

[41] I BARIN. Thermochemical data of pure substances.