Deep mineral resource exploration technology is affected by problems such as complex geological conditions and difficulties in remote detection, thus rendering it impossible to perform conventional mineral exploration in inaccessible areas. Therefore, remote detection methods must be developed urgently. Laser-induced breakdown spectroscopy (LIBS) offers the advantages of in-situ, noncontact, and multi-element simultaneous detection and can be applied broadly in remote material detection. However, the effects of the system parameters have not been comprehensively investigated, and most studies have focused on classification instead of quantitative analysis. The experimental parameters must be further optimized during remote detection to improve the remote detection capability. A remote LIBS detection system with variable focus based on a Galileo-type telescope is proposed to understand the effects of detection distance, delay time, and laser energy on plasma emission intensity. Subsequently, a parameter-optimization scheme is proposed. The quantitative performance of the remote LIBS system at different detection distances is evaluated using standard-curve and multivariate linear fitting methods. The results indicate improvement in the detection accuracy of remote LIBS measurements, which benefits field applications.

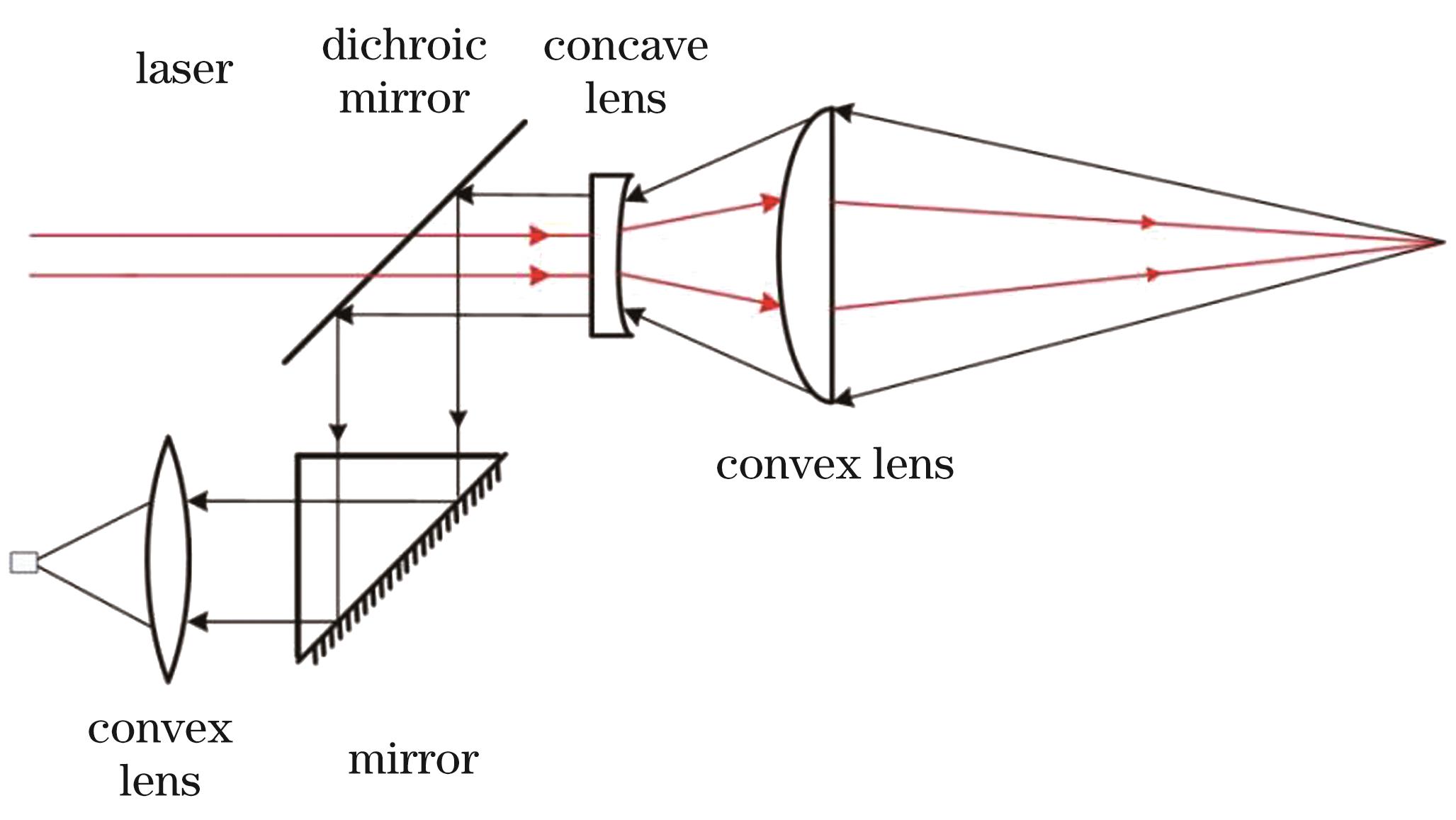

A remote LIBS detection system based on a Galileo-type telescope is designed. A coaxial optical path, in which laser focusing and signal acquisition share the same optical path, is utilized to render the system more compact. The focusing performance of the system is simulated using the Zemax software. The Nd∶YAG all-solid-state laser with a fundamental wavelength of 1064 nm and a pulse width of 10 ns is used as the excitation light source. The outgoing pulsed laser beam passes through a dichroic mirror into the Galileo-type telescope and is then focused onto the surface of the target to generate plasmas. The focus position of the laser is adjusted by varying the distance between the concave and convex lenses, thus enabling a detection range from 0.5 m to 5.0 m. The plasma emission obtained by the Galileo-type telescope, followed by the reflection through the dichroic mirror, is coupled to the transmission fiber through a convex lens with a focal length of 38.1 mm. Plasma spectra are obtained using a spectrometer with a wavelength range of 180?900 nm and a spectral resolution of 0.3 nm. The laser is operated in the internal trigger mode, and the spectrometer is triggered by the laser-pump synchronization signal, thus achieving timing control of the detection system. Aluminum alloy targets are selected for this experiment. Quantitative analyses are performed using the standard-curve method and multivariate linear fitting method; subsequently, the results are compared to determine the detection accuracy of the system.

Zemax simulations show that the laser-focusing spot size increases with the focusing distance (Table 1). Abundant spectral information is acquired from the typical LIBS spectral lines of copper?nickel?magnesium?aluminum alloy targets (Fig. 4). Time-resolved emission spectra of Ni I 352.45 nm, Al I 396.15 nm, Mg I 518.32 nm, and Cu I 521.82 nm at different detection distances are observed (Fig. 5). Although the line intensities are weak at a detection distance of 5.0 m, the characteristic emission spectra are clearly displayed (Fig. 6). Both the continuum background emission and characteristic emission of the spectra decrease with plasma evolution, resulting in a decreasing trend of plasma emission with a detection delay from 0 ns to 5000 ns (Fig. 7). An optimal detection delay of 200 ns is selected to obtain characteristic spectra with a high line intensity and favorable signal-to-noise ratio. The line intensity of each element increases with the laser energy. When the laser energy exceeds 80 mJ at a distance of 0.5 m, the line intensities saturate owing to the plasma shielding effect (Fig. 8). The spectral line intensity shows an approximate exponential attenuation as the detection distance increases from 0.5 m to 5.0 m at the laser energy of 80 mJ (Fig. 9). This is primarily because the focusing spot size increases with distance, which reduces the power density and degrades the laser ablation, thus weakening the obtained plasma signal intensity. Quantitative analyses are performed using the standard-curve method and multivariate linear fitting method, followed by a comparison of the prediction accuracy (Fig. 10). A mass fraction of 9% is selected for prediction and validation, and other mass fractions are used for training to establish calibration curves. The coefficients of determination (R2) of the calibration models at different distances exceed 0.989, and the average relative errors (AREs) of the predictions range from 5% to 8%. The AREs calculated using multivariate linear fitting method are less than 4%. This indicates that the prediction results obtained using multivariate linear fitting method are more similar to the reference values compared with those obtained using the standard-curve method. This study demonstrates the excellent qualitative and quantitative performances of a remote LIBS system, even at a detection distance of 5.0 m.

In this study, we investigate the qualitative and quantitative performances of metals using remote LIBS. A remote LIBS detection system using a coaxial optical path based on a Galileo-type telescope that can achieve substance component analysis within a distance of 0.5?5.0 m is designed. Zemax simulations of the focusing performance show that the laser-focusing spot increases with the focusing distance. The copper?nickel?magnesium?aluminum alloy target is selected to investigate the effects of the detection distance, delay time, and laser energy on the plasma emission intensity and the quantitative analytical capability of remote LIBS. The results show that the plasma emission decreases under a detection delay from 0 ns to 5000 ns, and that the line intensity of each element increases as the laser energy increases from 20 mJ to 250 mJ. The line intensities exhibit an approximately exponential attenuation with increasing detection distance. More importantly, the quantitative analytical performance of the LIBS system at different distances is evaluated based on six aluminum alloy targets using the standard-curve method and multivariate linear fitting method. A mass fraction of 9% is selected for prediction and validation, and other mass fractions are used for training to establish calibration curves. The R2values of the calibration models obtained at different distances exceed 0.989, and the AREs range between 5% and 8%. The AREs calculated using multivariate linear fitting method are less than 4%, thus proving that the system offers excellent qualitative and quantitative analytical capabilities within the detection range of 5.0 m. This study provides an experimental basis and data support for the optimization of remote LIBS equipment and demonstrates the significant potential of LIBS technology for remote qualitative and quantitative measurements.

AI Video Guide

AI Video Guide  AI Picture Guide

AI Picture Guide AI One Sentence

AI One Sentence