Mengjia Chen, Fuguang Chen, Zhi Chen, Meilin Gong, Xiaofeng Liu, Zhijun Ma. Research Progress on Mechanoluminescent Optical Fibers and Their Applications[J]. Laser & Optoelectronics Progress, 2023, 60(13): 1316009

Search by keywords or author

- Laser & Optoelectronics Progress

- Vol. 60, Issue 13, 1316009 (2023)

![Luminescence mechanism of mechanoluminescent materials[7, 40]. (a) Trap control type; (b) non-trap control type](/richHtml/lop/2023/60/13/1316009/img_01.jpg)

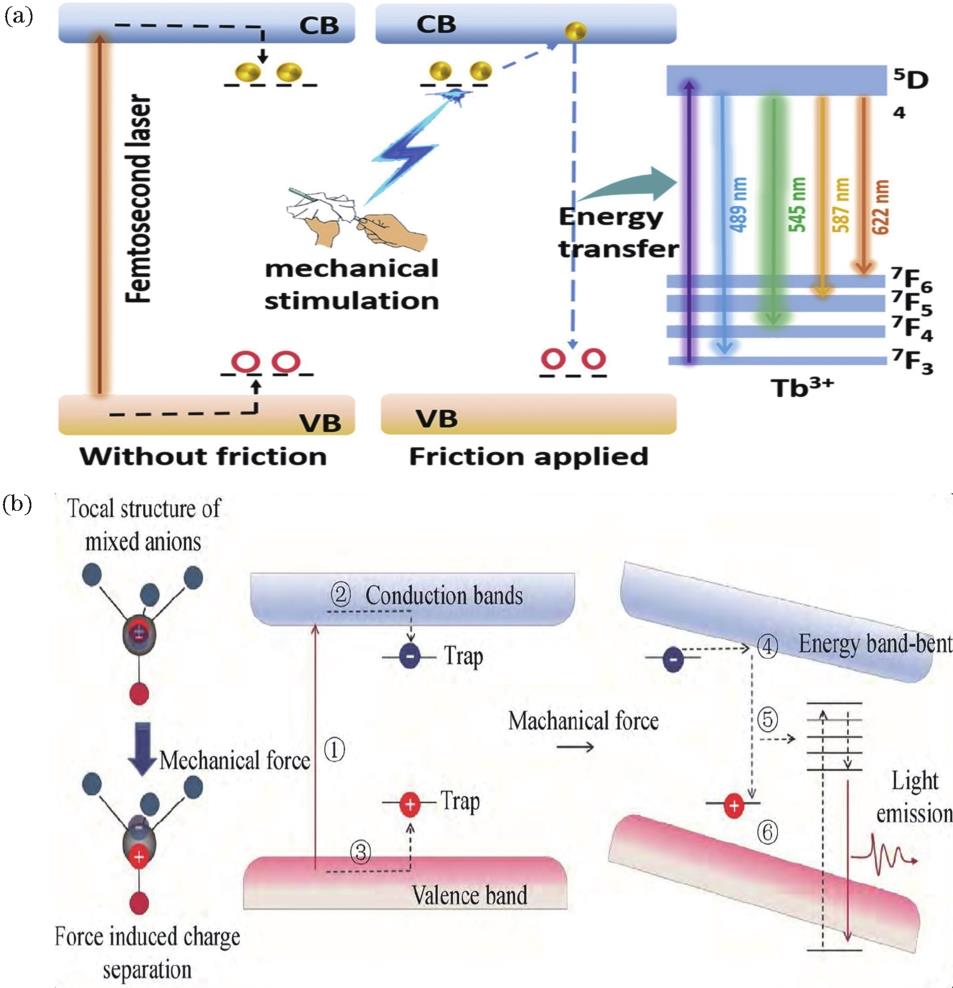

Fig. 1. Luminescence mechanism of mechanoluminescent materials[7, 40]. (a) Trap control type; (b) non-trap control type

![Core structure of mechanoluminescent fiber[9]. (a) Preparation and structure diagram of mechanoluminescent composite fiber; (b) (c) side SEM images of the mechanoluminescent fiber without outer PDMS at low and high magnification; (d) (e) cross section SEM images of the mechanoluminescent fiber at low and high magnification; (f) the change of mechanoluminescence intensity of mechanoluminescent fiber during repeated stretching and relaxation](/richHtml/lop/2023/60/13/1316009/img_02.jpg)

Fig. 2. Core structure of mechanoluminescent fiber[9]. (a) Preparation and structure diagram of mechanoluminescent composite fiber; (b) (c) side SEM images of the mechanoluminescent fiber without outer PDMS at low and high magnification; (d) (e) cross section SEM images of the mechanoluminescent fiber at low and high magnification; (f) the change of mechanoluminescence intensity of mechanoluminescent fiber during repeated stretching and relaxation

Fig. 3. Mechanoluminescent fiber based on cross-shaped elastic fiber[10]. (a) Preparation and structure diagram of mechanoluminescent fiber combined with ZnS∶Cu/PDMS and cross-shaped fiber; (b) SEM images of the cross-shaped fiber (top left) and the mechanoluminescent fiber (top right) and mechanoluminescence images during fiber stretching (bottom); (c) mechanoluminescence spectra of fiber stretched at different strain rates; (d) the change of mechanoluminescence intensity of fiber during cyclic stretching and release

Fig. 4. Schematic diagrams of mechanoluminescent fiber structure[46]. (a) Structure diagram of distributed organic mechanoluminescence fiber; (b) a dental retainer structure diagram of integrated mechanoluminescent fiber

Fig. 5. Ba2LaF7∶Tb3+ glass-ceramics mechanoluminescence fiber[40]. (a) Photo of glass-ceramics sample and its mechanoluminescence photo with knife scratching; (b) mechanoluminescence spectra and digital photos of glass-ceramics with different scraping forces; (c) photograph of the Ba2LaF7∶Tb3+ glass-ceramics fiber under ultraviolet light; (d) mechanoluminescence photos (left) and light intensity distribution (right) of glass-ceramics fiber after friction in different parts; (e) diagram of stress distribution detection using Ba2LaF7∶Tb3+ glass-ceramics fiber; (f) curve of light intensity ratio at both ends of fiber with friction position (left) and application diagram of railway traffic monitoring (right)

Fig. 6. Potential applications of mechanoluminescent fiber[40, 47-48]. (a) Underwater rescue; (b) road and bridge health and traffic monitoring; (c) tailor-made wearable mechanoluminescent textiles for human health and exercise monitoring; (d)-(f) smart textiles woven with SOEFS and spandex alternating as warp yarn and cotton as weft yarn for fabric display and motion sensing

Table 1. Summary and comparison of key parameters of representative mechanoluminescent optical fibers

Set citation alerts for the article

Please enter your email address