[1] Q FU, P ZHANG, L ZHUANG et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science & Technology(2022).

[2] G J ZHANG, D W NI, J ZOU et al. Inherent anisotropy in transition metal diborides and microstructure/property tailoring in ultra-high temperature ceramics—a review. Journal of the European Ceramic Society(2018).

[3] S K THIMMAPPA, B R GOLLA, VVB PPRASAD. Oxidation behavior of silicon-based ceramics reinforced diboride UHTC: a review. Silicon, 12049(2022).

[4] S MUNGIGUERRA, L SILVESTRONI, R SAVINO et al. Qualification and reusability of long and short fibre-reinforced ultra-refractory composites for aerospace thermal protection systems. Corrosion Science(2022).

[5] P ZHANG, Q G FU, C Y CHENG et al. Microstructure evolution of

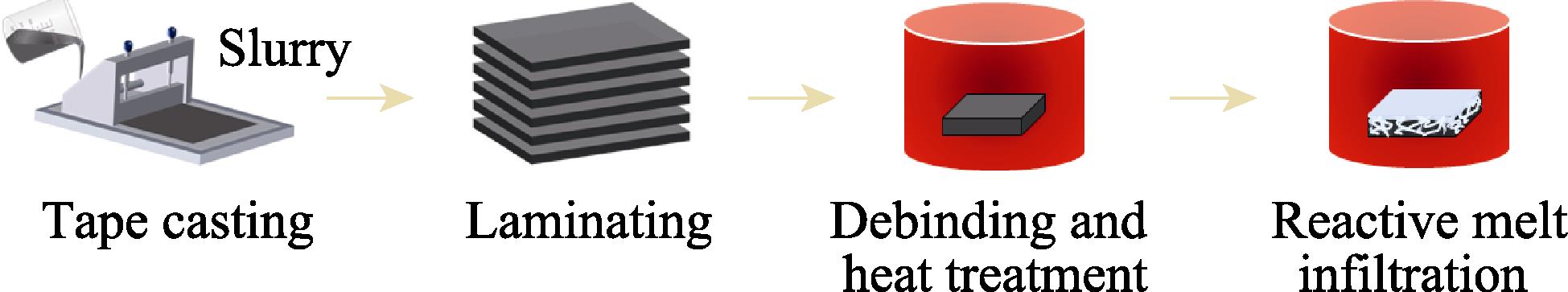

[6] A VINCI, L ZOLI, P GALIZIA et al. Reactive melt infiltration of carbon fibre reinforced ZrB2/B composites with Zr2Cu. Composites Part A: Applied Science and Manufacturing(2020).

[7] S R LEVINE, E J OPILA, M C HALBIG et al. Evaluation of ultra-high temperature ceramics for aeropropulsion use.. Journal of the European Ceramic Society(2002).

[8] B R GOLLA, A MUKHOPADHYAY, B BASU et al. Review on ultra-high temperature boride ceramics. Progress in Materials Science(2020).

[9] M M OPEKA, I G TALMY, J A ZAYKOSKI. Oxidation-based materials selection for 2000 ℃+hypersonic aerosurfaces: theoretical considerations and historical experience. Journal of Materials Science.

[10] S M ZHANG, S WANG, W LI et al. Microstructure and properties of W-ZrC composites prepared by the displacive compensation of porosity (DCP) method. Journal of Alloys and Compounds(2011).

[11] K Z LI, X T SHEN, H J LI et al. Ablation of the carbon/carbon composite nozzle-throats in a small solid rocket motor. Carbon(2011).

[12] Y L ZHANG, H HU, P F ZHANG et al. SiC/ZrB2-SiC-ZrC multilayer coating for carbon/carbon composites against ablation. Surface and Coatings Technology(2016).

[13] B YAN, Z F CHEN, J X ZHU et al. Effects of ablation at different regions in three-dimensional orthogonal C/SiC composites ablated by oxyacetylene torch at 1800 ℃. Journal of Materials Processing Technology.

[14] V VERMA, V CHEVERIKIN, R CÂMARA COZZA. Review: effect on physical, mechanical, and wear performance of ZrB2-based composites processed with or without additives. International Journal of Applied Ceramic Technology(2020).

[15] Y J LIU, Y F ZU, H L TIAN et al. Microstructure and mechanical properties of continuous carbon fiber-reinforced ZrB2-based composites

[16] A BALBO, D SCITI. Spark plasma sintering and hot pressing of ZrB2-MoSi2 ultra-high-temperature ceramics. Materials Science and Engineering: A(2008).

[17] W G FAHRENHOLTZ, G E HILMAS, I G TALMY et al. Refractory diborides of zirconium and hafnium. Journal of the American Ceramic Society(2007).

[18] J W ZIMMERMANN, G E HILMAS, W G FAHRENHOLTZ et al. Thermophysical properties of ZrB2 and ZrB2-SiC ceramics. Journal of the American Ceramic Society(2008).

[19] A REZAIE, W G FAHRENHOLTZ, G E HILMAS. Oxidation of zirconium diboride-silicon carbide at 1500 ℃ at a low partial pressure of oxygen. Journal of the American Ceramic Society(2006).

[20] J ZOU, G J ZHANG, C F HU et al. Strong ZrB2-SiC-WC ceramics at 1600 ℃. Journal of the American Ceramic Society(2012).

[21] E W NEUMAN, G E HILMAS, W G FAHRENHOLTZ. Mechanical behavior of zirconium diboride-silicon carbide-boron carbide ceramics up to 2200 ℃. Journal of the European Ceramic Society.

[22] L SILVESTRONI, H J KLEEBE, W G FAHRENHOLTZ et al. Super-strong materials for temperatures exceeding 2000 ℃. Scientific Reports(2017).

[23] L SILVESTRONI, D SCITI. Effects of MoSi2 additions on the properties of Hf- and Zr-B2 composites produced by pressureless sintering. Scripta Materialia(2007).

[24] L T ZHAO, C HOU, X C JIN et al. Oxidation behaviors of ZrB2-SiC ceramics with different porosity. Advanced Engineering Materials(2023).

[25] L SILVESTRONI, G MERIGGI, D SCITI. Oxidation behavior of ZrB2 composites doped with various transition metal silicides. Corrosion Science(2014).

[26] C D’AMICO, G BIANCHI, E PADOVANO et al. Effect of ZrB2 addition on the oxidation behavior of Si-SiC-ZrB2 composites exposed at 1500 ℃ in the air.. Journal of Applied Biomaterials & Functional Materials(2018).

[27] S H LEE, L FENG, C J BAE. Densification of ZrB2-SiC nanocomposites prepared using ZrSi2, B4C, and C additives. Journal of Materials Research(2017).

[28] A YOSHIASA, T TOBASE, H ARIMA-OSONOI et al. High-temperature diffraction experiments and phase diagram of ZrO2 and ZrSiO4. Zeitschrift Für Naturforschung B(2021).